This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins Hexagon Flange Head Cap Screw, part number 4900448, is a specialized fastener designed for use in commercial truck maintenance. Cummins, a renowned manufacturer in the industry, produces this screw to meet the demanding requirements of heavy-duty applications. This part is integral to ensuring the reliability and performance of various truck components.

Basic Concepts

A Hexagon Flange Head Cap Screw is a type of bolt characterized by its hexagonal head and a flange—a flat, circular plate—underneath the head. This design allows for efficient torque application and provides a larger bearing surface, which helps distribute the load more evenly 1. In the context of truck components, these screws are used to secure parts that require high strength and resistance to loosening.

Purpose and Role in Truck Operation

This Cummins part plays a significant role in the operation of a truck by securing critical components that are subject to vibration and high stress. Its applications range from fastening engine parts to securing chassis components. The screw’s design ensures that these parts remain firmly in place, contributing to the overall stability and safety of the vehicle 2.

Key Features

The 4900448 boasts several key features that make it suitable for heavy-duty applications. Its hexagonal head allows for easy tightening using a wrench or socket, while the flange provides additional resistance to loosening. The screw is made from high-quality materials that offer excellent tensile strength and corrosion resistance, ensuring durability in harsh operating environments 3.

Benefits

One of the primary benefits of the 4900448 is its enhanced stability. The flange design helps distribute the load more evenly, reducing the risk of the screw loosening over time. Additionally, the hexagonal head allows for precise torque application, ensuring that the screw is tightened to the manufacturer’s specifications. The material properties of the screw also contribute to its resistance to corrosion and wear, extending its service life.

Installation and Usage

Proper installation of the 4900448 is crucial for ensuring its effectiveness. It is recommended to use the appropriate torque settings specified by Cummins to avoid over-tightening or under-tightening. The screw should be installed in applications where high strength and resistance to vibration are required, such as in engine components or chassis assemblies.

Troubleshooting and Maintenance

Common issues with the 4900448 include loosening and corrosion. Regular inspections can help identify these problems early. If loosening is detected, the screw should be re-tightened to the specified torque settings. In cases of corrosion, the affected screw should be replaced to maintain the integrity of the fastening. Routine maintenance, such as cleaning and inspecting the screws, can help ensure their longevity and performance.

Cummins Overview

Cummins is a well-established manufacturer with a strong reputation in the automotive and heavy-duty truck industries. The company has a history of innovation and commitment to quality, producing components that meet the rigorous demands of commercial applications. Cummins’ focus on research and development ensures that their products, including the 4900448, are at the forefront of technology and reliability.

Cummins Hexagon Flange Head Cap Screw 4900448 in Engine Applications

The Cummins Hexagon Flange Head Cap Screw, part number 4900448, is a critical component in the assembly and maintenance of various engine models. This screw is engineered to provide robust fastening solutions, ensuring the integrity and performance of the engine systems it is used in.

Application in A1400 and A1700 Engines

In the A1400 and A1700 engines, the 4900448 screw is utilized in several key areas. These engines, known for their reliability and efficiency, require precise fastening to maintain operational standards. The screw’s design allows for secure attachment of components, contributing to the overall stability and longevity of the engine.

Application in A2000 and A2300 Engines

Similarly, in the A2000 and A2300 engines, the 4900448 screw plays a vital role. These engines, which are part of a series designed for heavy-duty applications, benefit from the screw’s ability to withstand high stress and torque. The screw’s flange head provides a larger surface area for tightening, ensuring that connections remain firm under demanding conditions.

Grouping of Engines

The engines A1400 and A1700, along with A2000 and A2300, are grouped based on their similar design philosophies and operational requirements. The use of the 4900448 screw across these engines highlights its versatility and importance in maintaining the structural and functional integrity of the engine systems. This commonality in usage underscores the screw’s critical role in the performance and durability of these engines.

Role of Part 4900448 Hexagon Flange Head Cap Screw in Engine Systems

The part 4900448 Hexagon Flange Head Cap Screw is an essential component in various engine systems, providing secure fastening and reliable performance across multiple applications.

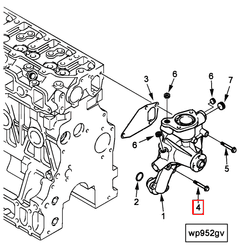

Fan Pilot Spacer

In the assembly of fan pilot spacers, the 4900448 screw ensures that the fan is correctly aligned and securely attached to the engine. This alignment is vital for the efficient operation of the cooling system, as it allows the fan to maintain optimal airflow over the radiator, ensuring the engine remains at an appropriate operating temperature.

Manifold

When used in manifold assemblies, the 4900448 screw plays a role in securing manifold components to the engine block or cylinder head. This secure attachment is important for maintaining the integrity of the manifold, which is responsible for distributing air and fuel mixture to the engine’s cylinders. Proper fastening prevents leaks and ensures consistent engine performance.

Exhaust

In exhaust systems, the 4900448 screw is utilized to fasten exhaust manifold components and catalytic converters to the engine. This secure connection is essential for maintaining the structural integrity of the exhaust system, preventing leaks that could lead to increased emissions and reduced engine efficiency.

Pump

For water pumps and other engine pumps, the 4900448 screw is used to attach the pump housing to the engine block. This secure attachment ensures that the pump operates efficiently, providing consistent coolant flow through the engine to prevent overheating.

Water System

In the broader water system of an engine, including components like the thermostat housing and water passages, the 4900448 screw ensures that all components are tightly secured. This is vital for maintaining the integrity of the cooling system, ensuring that coolant circulates effectively to regulate engine temperature.

Water Pump

Specifically for the water pump, the 4900448 screw is critical in attaching the pump to the engine block. This secure fastening ensures that the pump can operate without vibration or misalignment, which is essential for the reliable circulation of coolant throughout the engine.

Conclusion

Overall, the 4900448 Hexagon Flange Head Cap Screw is a versatile and reliable component that enhances the performance and durability of various engine systems by providing secure and stable fastening solutions.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.