This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

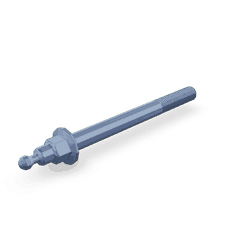

The 4900746 Captive Washer Cap Screw, manufactured by Cummins, is a specialized fastener designed for use in heavy-duty truck components. Cummins, a well-established name in the automotive industry, is known for its robust and reliable parts. This Cummins part is significant in the context of heavy-duty trucks due to its role in ensuring secure and efficient fastening in various mechanical systems.

Basic Concepts of Captive Washer Cap Screws

A Captive Washer Cap Screw is a type of fastener that includes an integrated washer, which is held in place by a collar or a step in the screw’s shaft. This design ensures that the washer remains in position during installation, reducing the risk of loss and ensuring consistent torque application 1. The screw typically consists of a head, a threaded shaft, and the captive washer. It functions by providing a secure fastening solution that distributes pressure evenly across the fastened materials, enhancing the integrity of the joint.

Purpose of the 4900746 Captive Washer Cap Screw

The 4900746 Captive Washer Cap Screw plays a role in the operation of a truck by securing critical components and assemblies. It is used in applications where consistent and reliable fastening is required, such as in engine mounts, chassis components, and various mechanical systems. By providing a secure attachment point, it helps maintain the structural integrity and performance of the truck.

Key Features

The 4900746 Captive Washer Cap Screw is designed with specific elements that contribute to its functionality and durability. It is typically made from high-strength materials, such as alloy steel, which provide resistance to corrosion and wear 2. The integrated washer is designed to distribute clamping force evenly, reducing the risk of damage to the fastened materials. Additionally, the screw features a hexagonal head for easy installation using standard tools.

Benefits

Using the 4900746 Captive Washer Cap Screw offers several advantages. Its design enhances reliability by ensuring that the washer remains in place, which is particularly important in high-vibration environments common in heavy-duty trucks 3. The ease of installation reduces the time required for maintenance tasks, and the durable construction contributes to long-term performance and reduced need for frequent replacements.

Installation Process

Proper installation of the 4900746 Captive Washer Cap Screw involves several steps to ensure optimal performance and longevity. First, the fastening area should be clean and free of debris. The screw should be aligned with the designated hole and started by hand to ensure proper engagement. Using a torque wrench, the screw should be tightened to the manufacturer’s specified torque setting to avoid over-tightening, which could damage the screw or the fastened materials.

Troubleshooting Common Issues

Typical problems with Captive Washer Cap Screws may include loosening due to vibration, corrosion, or damage from improper installation. To address these issues, regular inspections should be conducted to identify any signs of wear or loosening. If corrosion is present, the affected areas should be cleaned, and a corrosion-resistant coating may be applied. In cases of damage, the screw should be replaced with a new one to maintain the integrity of the fastening.

Maintenance Tips

To prolong the life of the 4900746 Captive Washer Cap Screw and ensure continued reliable operation, regular maintenance practices should be followed. This includes periodic inspections for signs of wear, corrosion, or loosening. Applying a corrosion-resistant coating can help protect the screw from environmental factors. Additionally, ensuring that the screw is tightened to the correct torque specification during installation will help maintain the integrity of the fastening.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the automotive industry, particularly in the heavy-duty truck sector. The company’s product range includes engines, powertrain components, and aftermarket parts, all of which are designed to deliver reliable performance and durability. Cummins’ commitment to innovation and quality has made it a trusted name among fleet operators and maintenance professionals.

Captive Washer Cap Screw (Part 4900746) in Cummins Engines

The Captive Washer Cap Screw, part number 4900746, is a critical component in several Cummins engine models. This part is designed to secure various engine components, ensuring they remain tightly fastened and properly aligned during operation. Its application spans across multiple engine series, providing a reliable fastening solution.

A1400 and A1700 Engines

In the A1400 and A1700 engines, the Captive Washer Cap Screw is utilized in several key areas. It is often found securing the cylinder head to the engine block, ensuring that the combustion chamber remains sealed. This is crucial for maintaining engine efficiency and preventing leaks. Additionally, this part is used in the mounting of ancillary components such as the alternator and various brackets, ensuring that these parts remain securely in place under the dynamic conditions of engine operation.

A2000 and A2300 Engines

For the A2000 and A2300 engines, the Captive Washer Cap Screw plays a similar role but is also employed in more complex assemblies. In these engines, it is used to secure the turbocharger housing, which is vital for maintaining the integrity of the forced induction system. The screw also finds use in the mounting of the exhaust manifold, where it helps to keep the manifold tightly fastened to the engine block, preventing any exhaust leaks that could compromise engine performance.

Common Applications

Across all these engines, the Captive Washer Cap Screw is a versatile component. It is often used in conjunction with a captive washer, which is designed to stay in place and prevent the screw from loosening due to vibration. This feature is particularly important in high-vibration environments such as those found in diesel engines. The screw’s design ensures that it can withstand the stresses of engine operation, providing a long-lasting and reliable fastening solution.

Role of Part 4900746 Captive Washer Cap Screw in Engine Systems

The 4900746 Captive Washer Cap Screw is integral to the assembly and secure functioning of various engine components. In the flywheel housing, this screw ensures that the housing remains firmly attached to the engine block, preventing any misalignment or movement that could affect the engine’s performance.

When considering the general housing components, the 4900746 screw plays a significant role in maintaining the structural integrity of these parts. It secures housing units to the engine, ensuring that all internal components are properly aligned and operate efficiently.

In the context of the flywheel, the 4900746 screw is used to attach the flywheel to the crankshaft. This connection is essential for the smooth transfer of power from the engine to the transmission system. The screw’s captive washer design helps in distributing the load evenly, reducing the risk of wear and tear on the flywheel.

For the motor assembly, the 4900746 screw is often employed to fasten motor mounts and other critical components. This ensures that the motor remains stable during operation, which is vital for consistent performance and longevity of the engine.

Lastly, in starting systems, the 4900746 screw is used to secure the starter motor to the engine block. This is important for the reliable engagement of the starter gear with the flywheel, ensuring that the engine starts smoothly and reliably.

Overall, the 4900746 Captive Washer Cap Screw is a key component in maintaining the structural and functional integrity of various engine systems.

Conclusion

The 4900746 Captive Washer Cap Screw is a vital component in the maintenance and operation of heavy-duty truck engines. Its design and features ensure reliable fastening in high-vibration environments, contributing to the overall performance and durability of the engine. Proper installation, regular maintenance, and timely replacement are essential to maximize the benefits of this Cummins part.

-

Andrew Brown Jr, Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles, National Academy of Sciences, 2010.

↩ -

John Dixon, Modern Diesel Technology: Heating, Ventilation, Air Conditioning, Refrigeration, 2nd Edition, Cengage Learning, 2014.

↩ -

Konrad Reif Ed, Diesel Engine Management Systems and Components, Springer Vieweg, 2014.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.