4924726

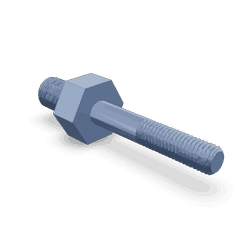

Studded Hexagon Cap Screw

Cummins®

AVAILABLE

7 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 4924726 Studded Hexagon Cap Screw is a specialized fastener produced by Cummins, a leading manufacturer in the commercial truck industry. This screw is designed for use in various applications within commercial trucks, ensuring secure and reliable fastening of components. Its robust construction and precise engineering make it suitable for the demanding conditions encountered in truck operations.

Basic Concepts of Studded Hexagon Cap Screws

Studded hexagon cap screws are a type of fastener characterized by a hexagonal head and a threaded shank that extends beyond the nut or component being fastened. These screws are commonly used in mechanical assemblies to secure components together. The hexagonal head allows for easy tightening and loosening using a wrench or socket, while the threaded shank provides a strong and durable connection. In applications where high strength and resistance to vibration are required, studded hexagon cap screws are often preferred 1.

Purpose of the 4924726 Studded Hexagon Cap Screw in Truck Operation

This Cummins part plays a significant role in the operation and maintenance of commercial trucks. It is utilized in various engine components and other critical areas where secure fastening is necessary. This screw helps maintain the integrity of engine assemblies, ensuring that parts remain firmly in place under the stress of operation. Its application extends to other areas of the truck, contributing to the overall reliability and performance of the vehicle.

Key Features

The 4924726 Studded Hexagon Cap Screw boasts several key features that enhance its performance and durability. Its design includes a hexagonal head for easy manipulation with standard tools. The screw is made from high-quality materials, typically alloy steel, which provides excellent strength and resistance to wear. The threading is precise, ensuring a secure fit and reducing the risk of loosening over time. Additionally, the screw may feature a studded end that extends beyond the nut, offering extra stability and preventing rotation during operation 2.

Benefits

This Cummins part offers numerous benefits that make it an ideal choice for commercial truck applications. Its improved fastening strength ensures that components remain securely attached, even under demanding conditions. The screw’s resistance to vibration helps prevent loosening, which is crucial in the dynamic environment of a truck. Furthermore, its longevity in harsh operating conditions ensures that it maintains performance over time, reducing the need for frequent replacements.

Installation Process

Proper installation of the 4924726 Studded Hexagon Cap Screw is vital to ensure secure and effective fastening. Begin by aligning the screw with the designated hole in the component. Using a wrench or socket, carefully tighten the screw until it reaches the specified torque. It is important to follow torque specifications provided by the manufacturer to avoid over-tightening, which can damage the screw or the component, or under-tightening, which can lead to insecure fastening. Best practices include using a torque wrench for precise application and ensuring that the screw is perpendicular to the surface to which it is being fastened.

Troubleshooting Common Issues

Common problems associated with studded hexagon cap screws include loosening, corrosion, and damage. To address loosening, ensure that the screw is properly torqued during installation and periodically check for tightness during maintenance. Corrosion can be mitigated by using screws made from corrosion-resistant materials and applying protective coatings where necessary. If damage is detected, such as stripped threads or a deformed head, the screw should be replaced to maintain the integrity of the fastening.

Maintenance Tips

Regular maintenance of studded hexagon cap screws is essential to ensure ongoing performance and reliability. Inspection procedures should include checking for signs of loosening, corrosion, or damage. Screws should be tightened to the specified torque if loosening is detected. Corrosion can be addressed by cleaning the screw and applying a protective coating. Replacement guidelines suggest that screws showing significant wear or damage should be replaced promptly to prevent failure.

Cummins: A Brief Overview

Cummins Inc. is a renowned manufacturer in the commercial truck industry, known for its commitment to quality and innovation. Founded in 1919, Cummins has a long history of producing reliable and high-performance engines and components. The company’s product range includes engines, powertrains, and related technologies, all designed to meet the rigorous demands of commercial trucking. Cummins’ reputation for excellence is built on its dedication to engineering excellence, customer satisfaction, and continuous improvement 3.

Studded Hexagon Cap Screw 4924726 in Cummins Engines

The Studded Hexagon Cap Screw 4924726, manufactured by Cummins, is a critical component in several of their engine models. This part is integral to the assembly and functionality of the engines, ensuring secure fastening and stability.

QSK50 CM2150 K107 and QSK50 CM2150 MCRS

In the QSK50 CM2150 K107 and QSK50 CM2150 MCRS engines, the Studded Hexagon Cap Screw 4924726 is utilized in various applications where robust fastening is required. These engines, known for their reliability and performance, depend on this screw to maintain the integrity of critical assemblies. The screw’s design ensures that it can withstand the operational stresses and environmental conditions these engines encounter.

QSK50 CM2350 K108

Similarly, in the QSK50 CM2350 K108 engine, the Studded Hexagon Cap Screw 4924726 plays a vital role. This engine, part of Cummins’ high-performance lineup, requires precise and durable components to function optimally. The screw’s studded hexagon head provides a secure grip, while its robust construction ensures it can handle the demanding conditions of heavy-duty operations.

The use of the Studded Hexagon Cap Screw 4924726 across these engines highlights its importance in maintaining the structural integrity and operational efficiency of Cummins’ engine designs.

Component Usage

This part is integral to the secure assembly and operation of various engine components. In the module, this screw ensures that the module housing is firmly attached to the engine block, providing a stable platform for the module’s electronics and sensors. Its studded design allows for a robust connection, which is essential for withstanding the vibrations and stresses encountered during engine operation.

Within the engine control system, the 4924726 screw plays a significant role in mounting the engine control unit (ECU) to the engine bay. This secure attachment is vital for maintaining the ECU’s position and ensuring that its connections to various sensors and actuators remain intact. The screw’s hexagonal head facilitates easy tightening and removal using standard tools, which is beneficial during maintenance or upgrades.

Additionally, the 4924726 screw is used in the attachment of sensor brackets and wiring harnesses to the engine block. This ensures that sensors are positioned accurately for optimal performance and that wiring is neatly organized and protected from engine heat and moving parts. The studded feature of the screw provides extra stability, reducing the risk of sensor misalignment or wire damage over time.

Conclusion

In summary, the 4924726 studded hexagon cap screw is a versatile fastener that contributes to the reliable operation and durability of engine components by providing secure and stable connections.

-

Van Gelder, Kirk T. Fundamentals of Automotive Technology Principles and Practice. Jones Bartlett Learning, 2018.

↩ -

Stiesch, Gunnar. Modeling Engine Spray and Combustion Processes. Springer Verlag, 2003.

↩ -

Hick, Hannes, Klaus Kupper, and Helfried Sorger. Systems Engineering for Automotive Powertrain Development. Springer, 2021.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.