4924729

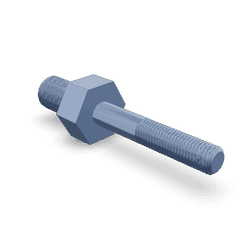

Studded Hexagon Cap Screw

Cummins®

AVAILABLE

More than 10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 4924729 Studded Hexagon Cap Screw is a specialized fastener produced by Cummins, a leading manufacturer in the commercial truck industry. This screw is designed for use in various applications within commercial trucks, providing reliable fastening solutions that contribute to the overall performance and durability of truck components.

Basic Concepts of Studded Hexagon Cap Screws

A studded hexagon cap screw is a type of fastener characterized by a hexagonal head and a threaded shank that extends beyond the nut or component it secures. These screws are commonly used in mechanical systems where a permanent or semi-permanent fastening is required. They function by converting torque applied to the hexagonal head into clamping force, which holds components together securely 1.

Purpose of the 4924729 Studded Hexagon Cap Screw in Truck Operations

The 4924729 Studded Hexagon Cap Screw plays a role in the operation and maintenance of commercial trucks by securing various components such as engine parts, transmission assemblies, and chassis elements. Its design allows for efficient assembly and disassembly, facilitating routine maintenance and repairs. The screw’s application in these critical areas ensures that truck components remain securely fastened under varying operational conditions 2.

Key Features of the 4924729 Studded Hexagon Cap Screw

The 4924729 Studded Hexagon Cap Screw is constructed with several design and construction features that enhance its performance. It is made from high-strength materials, typically alloy steel, which provides durability and resistance to wear. The screw features a coarse thread type, which allows for quick and secure fastening. Additionally, the studded design extends beyond the nut, offering increased leverage during installation and removal 3.

Benefits of Using the 4924729 Studded Hexagon Cap Screw

Using the 4924729 Studded Hexagon Cap Screw offers several advantages. Its high-strength material composition contributes to increased durability, making it suitable for heavy-duty applications. The screw’s design provides resistance to vibration, which helps maintain secure fastenings in dynamic environments. Furthermore, the hexagonal head allows for easy installation and removal using common tools, enhancing efficiency during maintenance procedures.

Installation and Usage Guidelines

Proper installation of the 4924729 Studded Hexagon Cap Screw involves several steps. Begin by ensuring that the mating surfaces are clean and free of debris. Use a torque wrench to apply the specified torque, which ensures that the screw is tightened to the manufacturer’s recommendations without overtightening. Recommended tools include a socket wrench with a hexagonal socket that matches the screw’s head size. Follow the torque specifications provided by Cummins to achieve optimal performance and longevity.

Troubleshooting Common Issues

Common issues with studded hexagon cap screws include loosening, corrosion, and damage. To address loosening, re-torque the screw to the specified value and ensure that the mating surfaces are clean and free of contaminants. Corrosion can be mitigated by applying an anti-seize compound during installation, which protects the screw from environmental factors. If damage is detected, replace the screw with a new one to maintain the integrity of the fastening.

Maintenance Tips

Regular maintenance of studded hexagon cap screws is important to ensure longevity and reliable performance. Inspect screws at recommended intervals for signs of wear, corrosion, or loosening. Cleaning procedures should include removing any buildup or contaminants from the screw and mating surfaces. Applying a protective coating or anti-seize compound during reinstallation can enhance the screw’s performance and lifespan.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company’s commitment to excellence is reflected in its diverse product range, which includes engines, powertrain components, and aftermarket parts designed to meet the demanding requirements of commercial trucking applications.

Integration of Studded Hexagon Cap Screw (Part 4924729) in Cummins Engines

The Studded Hexagon Cap Screw, part number 4924729, manufactured by Cummins, is a critical component in the assembly and maintenance of several Cummins engine models. This part is integral to the structural integrity and operational efficiency of the engines, ensuring secure fastening in various applications.

QSK60 CM850 MCRS and QSK95 CM2350 Engines

In the QSK60 CM850 MCRS and QSK95 CM2350 engines, the 4924729 Studded Hexagon Cap Screw is utilized in multiple critical areas. These engines, known for their robust design and high performance, require reliable fastening solutions to maintain the alignment and stability of engine components under extreme conditions. The studded hexagon cap screw provides the necessary strength and durability, ensuring that the engine parts remain securely fastened, thereby enhancing the overall performance and longevity of the engine.

QSK95 CM2350 K111 and K113 Variants

The QSK95 CM2350 K111 and K113 variants also benefit from the use of the 4924729 Studded Hexagon Cap Screw. These engines, which are part of the Cummins QSK series, are designed for heavy-duty applications and require components that can withstand high stress and frequent vibrations. The studded hexagon cap screw is strategically placed in areas where it needs to provide maximum support and resistance to loosening, ensuring that the engine operates smoothly and efficiently.

The use of this specific screw in these engines highlights Cummins’ commitment to quality and reliability. The studded hexagon cap screw’s design allows for easy installation and removal, which is crucial during maintenance and repair operations. Its robust construction ensures that it can handle the demanding environments these engines operate in, contributing to the overall durability and performance of the engine.

Role of Part 4924729 Studded Hexagon Cap Screw in Engine Systems

In the realm of engine systems, the 4924729 Studded Hexagon Cap Screw is instrumental in ensuring the secure assembly and reliable operation of various components. This screw is often utilized in the fastening of the Engine Control Module (ECM) and the Fuel Control Module (FCM), both of which are pivotal in the management and regulation of engine performance.

Engine Control Module (ECM)

The ECM is the brain of the engine system, responsible for processing data from various sensors and making real-time adjustments to optimize engine performance. The 4924729 Studded Hexagon Cap Screw plays a significant role in securing the ECM to its mounting bracket. This ensures that the module remains stable and vibration-free, which is essential for accurate sensor readings and consistent performance. The screw’s studded design provides additional grip, reducing the likelihood of loosening over time, even under the dynamic conditions of engine operation.

Fuel Control Module (FCM)

The FCM is another component where the 4924729 Studded Hexagon Cap Screw is commonly employed. This module regulates the fuel delivery system, ensuring that the engine receives the precise amount of fuel required for efficient combustion. Secure fastening of the FCM is vital to maintain the integrity of the fuel system. The studded hexagon cap screw ensures that the module is firmly attached to its housing, preventing any potential misalignment that could disrupt fuel flow and affect engine performance.

Conclusion

In summary, the 4924729 Studded Hexagon Cap Screw is a key component in the assembly and maintenance of critical engine modules. Its robust design and secure fastening capabilities contribute to the overall reliability and performance of the engine system.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.