This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 4936436 Studded Hexagon Cap Screw is a specialized fastener produced by Cummins, a well-established manufacturer known for its high-quality components in the automotive industry. This screw is specifically designed for use in commercial trucks, where it plays a role in securing various components and assemblies. Its robust design and reliable performance make it a preferred choice for maintaining the integrity and functionality of truck systems.

Basic Concepts of Studded Hexagon Cap Screws

A studded hexagon cap screw is a type of fastener characterized by a hexagonal head and a threaded shank that extends beyond the head, allowing it to be used with a nut. These screws are commonly employed in mechanical assemblies to secure components together. They function by providing a strong, stable connection that can withstand significant stress and vibration, ensuring that parts remain firmly in place during operation 1.

Role in Truck Operation

The 4936436 Studded Hexagon Cap Screw is integral to the operation and maintenance of commercial trucks. It is used in various truck systems, including the engine, transmission, and chassis. By securing critical components, it helps maintain the structural integrity and performance of the truck. Its applications range from fastening engine mounts to securing transmission components, ensuring that all parts function as intended under demanding conditions 2.

Key Features

The 4936436 Studded Hexagon Cap Screw boasts several key features that enhance its performance. Its design includes a hexagonal head, which allows for easy tightening and loosening using a wrench. The screw is made from high-strength materials, typically alloy steel, which provides excellent durability and resistance to wear. Additionally, the extended shank allows for greater flexibility in assembly, enabling it to be used with a variety of nuts and washers to suit different applications.

Benefits

The 4936436 Studded Hexagon Cap Screw offers several benefits that make it an ideal choice for commercial truck applications. Its high-strength material composition ensures improved durability, allowing it to withstand the rigors of heavy-duty use. The screw’s design also provides resistance to vibration, which is crucial in maintaining secure fastenings in dynamic environments. Furthermore, its ease of installation, thanks to the hexagonal head, simplifies the assembly process and reduces the risk of damage to the screw or surrounding components.

Installation Process

Proper installation of the 4936436 Studded Hexagon Cap Screw is crucial for ensuring secure fastening. The process involves several steps: First, ensure that the mating surfaces are clean and free of debris. Next, align the screw with the designated hole and begin threading it by hand to avoid cross-threading. Once the screw is started, use a wrench to tighten it to the specified torque, ensuring a secure fit without over-tightening, which could damage the screw or the component being fastened. It is also advisable to use a thread locker to enhance the screw’s resistance to vibration.

Troubleshooting Common Issues

Common issues with studded hexagon cap screws include loosening due to vibration, corrosion, and damage from over-tightening. To address these problems, regular inspections should be conducted to check for signs of wear or corrosion. If a screw is found to be loose, it should be re-tightened to the specified torque, and a thread locker should be applied if not already used. In cases of corrosion, the affected screw should be replaced to prevent further degradation. Over-tightened screws may require replacement if they are damaged.

Maintenance Tips

To ensure the longevity and reliable performance of the 4936436 Studded Hexagon Cap Screw, regular maintenance is recommended. This includes periodic inspections to check for signs of wear, corrosion, or loosening. Any screws showing signs of damage should be replaced promptly to maintain the integrity of the assembly. Additionally, applying a thread locker during installation can help prevent loosening due to vibration, further enhancing the screw’s performance over time.

Cummins: Manufacturer Overview

Cummins is a renowned manufacturer with a rich history in the automotive industry, particularly in the production of high-quality components for commercial vehicles. The company is known for its commitment to innovation, quality, and reliability. Cummins’ extensive range of products, including the 4936436 Studded Hexagon Cap Screw, reflects its dedication to providing solutions that meet the demanding requirements of commercial truck applications.

Integration of Studded Hexagon Cap Screw (Part 4936436) in Cummins Engines

The Studded Hexagon Cap Screw, part number 4936436, manufactured by Cummins, is a critical component in the assembly and maintenance of several Cummins engine models. This part is integral to the structural integrity and operational efficiency of the engines, ensuring that various components are securely fastened and aligned.

Application in QSC8.3 CM850 (CM2850) Engines

In the QSC8.3 CM850 (CM2850) engines, the 4936436 Studded Hexagon Cap Screw is utilized in multiple applications. It is often employed in securing the engine block to the cylinder head, ensuring that the combustion chamber is properly sealed. Additionally, this screw is used in fastening various engine mounts and brackets, which are essential for maintaining the engine’s position within the vehicle and reducing vibration.

Application in QSC9 CM2250/QSL9 CM2250 Engines

Similarly, in the QSC9 CM2250 and QSL9 CM2250 engines, the 4936436 Studded Hexagon Cap Screw plays a pivotal role. It is used extensively in the assembly of the engine block, where it helps to secure the block to the engine’s foundation. This screw is also critical in fastening the engine’s ancillary components, such as the alternator, water pump, and various brackets, ensuring that these parts remain securely in place under operational stresses.

The use of the 4936436 Studded Hexagon Cap Screw in these engines underscores its importance in maintaining the structural integrity and operational efficiency of the engines. Its robust design and reliable performance make it an essential component in the assembly and maintenance of Cummins engines.

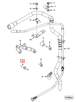

Role of Part 4936436 Studded Hexagon Cap Screw in Engine Systems

The 4936436 studded hexagon cap screw is integral to the assembly and maintenance of various engine components, ensuring secure fastening and reliable operation.

In the breather system, this screw is employed to fasten the breather cap to the crankcase. The breather system is designed to allow air to enter and exit the crankcase, maintaining atmospheric pressure and preventing the buildup of harmful gases. The secure attachment provided by the 4936436 screw ensures that the breather cap remains firmly in place, which is essential for the efficient functioning of the breather system.

Within the crankcase, the 4936436 screw is used to attach various components such as inspection covers, oil level indicators, and other accessories. The crankcase houses the crankshaft and connecting rods, and it is vital that all attached components are securely fastened to prevent leaks and ensure the structural integrity of the engine. The studded design of the hexagon cap screw provides additional stability and resistance to vibration, which is particularly important in the dynamic environment of an engine.

Overall, the 4936436 studded hexagon cap screw plays a significant role in maintaining the integrity and functionality of the breather and crankcase systems, contributing to the overall performance and reliability of the engine.

Conclusion

The 4936436 Studded Hexagon Cap Screw is a vital component in the automotive industry, particularly for commercial trucks and Cummins engines. Its robust design, reliable performance, and ease of installation make it an essential part for securing various components and assemblies. Regular maintenance and proper installation are crucial for ensuring the longevity and reliable operation of this screw, contributing to the overall efficiency and safety of the vehicle.

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.