This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

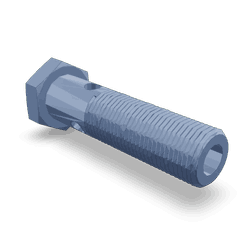

The 4940217 Banjo Connector Screw by Cummins is a specialized component used in commercial trucks. Manufactured by Cummins, a well-established name in the automotive industry, this part is integral to various fluid transfer systems within trucks. A banjo connector screw is a type of fitting used to connect hoses to other components in automotive systems, ensuring secure and leak-proof connections.

Basic Concepts of Banjo Connector Screws

Banjo connector screws are designed to facilitate the connection between hoses and fittings in fluid transfer systems. Their design typically includes a bolt with an integrated fitting that allows hoses to be clamped securely. This setup is commonly used in hydraulic, fuel, and brake systems where maintaining a sealed connection is vital. The banjo connector’s role is to provide a reliable interface that can withstand pressure and vibration, ensuring the efficient transfer of fluids 1.

Purpose of the 4940217 Banjo Connector Screw

The 4940217 Banjo Connector Screw is specifically designed for use in commercial trucks, where it plays a role in connecting various fluid systems. It is commonly applied in hydraulic, fuel, or brake systems, where it ensures secure and leak-proof connections. By providing a robust interface between hoses and fittings, this component helps maintain the integrity of the fluid transfer system, contributing to the overall performance and safety of the truck.

Key Features

The 4940217 Banjo Connector Screw boasts several key features that enhance its performance and durability. It is constructed from high-quality materials, ensuring resistance to corrosion and wear. The screw features a specific thread type that allows for secure fastening, and it is rated to withstand certain pressure levels, making it suitable for high-demand applications. Design enhancements may include sealing washers or O-rings to improve the seal integrity and prevent leaks.

Benefits

Using the 4940217 Banjo Connector Screw offers several advantages. It contributes to improved system reliability by ensuring secure and leak-proof connections. The design of the screw facilitates ease of installation, reducing downtime during maintenance procedures. Its resistance to corrosion extends the component’s lifespan, leading to long-term cost savings due to reduced maintenance needs. Additionally, the robust construction of the screw ensures it can withstand the harsh conditions typical in commercial truck operations.

Installation Process

Proper installation of the 4940217 Banjo Connector Screw is essential to ensure a secure and efficient connection. The process involves using the appropriate tools to attach the screw to the fitting, ensuring the hose is correctly aligned. Torque specifications should be followed to achieve the proper tightness without over-tightening, which could damage the fitting or the screw. Best practices include inspecting the connection for leaks after installation and periodically checking the tightness to maintain a secure fit.

Troubleshooting and Maintenance

Common issues with banjo connector screws include leaks, corrosion, and wear. Regular maintenance practices can help prolong the lifespan of the connector. This includes inspecting the connection for signs of leaks, checking for corrosion, and looking for any signs of wear on the screw or fitting. Addressing these issues promptly can prevent more significant problems and ensure the continued reliability of the fluid transfer system.

Safety Considerations

When working with banjo connector screws, it is important to follow safety guidelines to prevent accidents. This includes proper handling of the component to avoid injury, using personal protective equipment such as gloves and safety glasses, and performing system pressure checks to ensure the connection is secure before operating the vehicle. Adhering to these safety practices helps maintain a safe working environment and prevents potential hazards associated with fluid leaks or system failures.

Cummins Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its commitment to quality and innovation. With a rich history of producing reliable automotive components, Cummins has established a strong reputation for excellence. The company’s product range includes engines, powertrains, and various automotive parts, all designed to meet the demanding requirements of commercial truck operations. Cummins’ dedication to quality is evident in its manufacturing processes and the performance of its products, making it a trusted name in the industry.

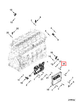

Role of the 4940217 Banjo Connector Screw in Engine Systems

The 4940217 Banjo Connector Screw is integral to the efficient operation of various engine components. Its primary function is to facilitate secure and leak-proof connections in hydraulic and fuel systems.

Connection to Oil Pressure Switch

In the context of an oil pressure switch, the Banjo Connector Screw ensures a reliable connection between the switch and the engine’s oil gallery. This connection is vital for accurate oil pressure readings, which are essential for the Engine Control Module (ECM) to make real-time adjustments to engine performance.

Integration with Sensor Adapter

When used with a sensor adapter, the Banjo Connector Screw plays a key role in maintaining the integrity of the sensor’s connection to the engine. This is particularly important in high-pressure environments where any leak could result in inaccurate sensor readings, potentially leading to suboptimal engine performance.

Application in Pressure Switch Kit

Within a pressure switch kit, the Banjo Connector Screw is employed to connect the switch to the engine’s hydraulic lines. This connection is fundamental for the switch to monitor and regulate pressure levels, ensuring the engine operates within safe parameters.

Role in Engine Control Systems

In engine control systems, the Banjo Connector Screw is often used to connect various sensors and switches to the engine. Its robust design ensures that these connections remain secure under varying engine conditions, contributing to the overall reliability and performance of the engine control system.

General Usage in Engine Systems

Across different engine systems, the 4940217 Banjo Connector Screw is a common component due to its ability to provide a secure, leak-proof connection in high-pressure environments. Its application extends beyond specific components, playing a supportive yet significant role in the overall functionality and efficiency of engine systems.

Conclusion

The 4940217 Banjo Connector Screw by Cummins is a critical component in the maintenance and operation of commercial trucks. Its design and features ensure secure, leak-proof connections in various fluid systems, contributing to the overall performance and safety of the vehicle. Proper installation, regular maintenance, and adherence to safety guidelines are essential to maximize the benefits of this component.

-

Ferrari, Alessandro, and Pietro Pizzo. Injection Technologies: Mixture Formation Strategies. SAE International, 2022.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.