This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

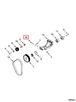

The Preload Adjusting Screw, part number 4948096, is a component manufactured by Cummins, a prominent entity in diesel engine technology. This part is integral to the operation of heavy-duty truck engines, ensuring optimal performance and longevity. Cummins, known for its commitment to innovation and quality, designs this part to meet the demanding requirements of commercial and industrial applications 1.

Basic Concepts of Preload Adjusting Screw

Preload refers to the initial tension applied to a mechanical system, which ensures components remain in proper contact under operational conditions 2. A preload adjusting screw is used to fine-tune this tension. In an engine, it operates by allowing technicians to adjust the clearance between moving parts, which is vital for maintaining efficiency and reducing wear. The screw’s role is to provide a means of calibration that can be adjusted as needed throughout the engine’s service life.

Purpose of the Preload Adjusting Screw

This Cummins part plays a role in the operation of a truck engine by allowing precise adjustments to the clearance between components, such as bearings or valve mechanisms. This adjustment is crucial for maintaining the engine’s performance and longevity. By ensuring that parts operate within specified tolerances, the screw helps to minimize friction and wear, which can lead to improved engine efficiency and reduced maintenance requirements 3.

Key Features

The Preload Adjusting Screw is designed with specific characteristics that enhance its functionality. It is typically made from high-strength materials to withstand the rigors of engine operation. The screw features a threaded design that allows for fine adjustments, and it may include a locking mechanism to secure the setting. These design elements contribute to the screw’s reliability and ease of use during maintenance procedures.

Benefits

Using the Preload Adjusting Screw offers several advantages. It contributes to improved engine efficiency by ensuring that components operate with minimal clearance, which can reduce energy loss due to friction. Additionally, by maintaining proper clearances, the screw helps to reduce wear on engine components, potentially extending the engine’s service life. The adjustability of the screw also simplifies maintenance, allowing for quick and precise adjustments without the need for specialized tools.

Installation Process

Installing the Preload Adjusting Screw requires careful attention to detail. The process typically involves loosening the locking mechanism, if present, and turning the screw to achieve the desired preload. Technicians may use a torque wrench to ensure that the screw is tightened to the manufacturer’s specifications. It is important to follow the engine’s service manual for precise instructions, as incorrect installation can lead to engine damage or reduced performance.

Troubleshooting Common Issues

Common issues with preload adjusting screws can include improper settings, which may lead to increased wear or reduced engine performance. If an engine exhibits unusual noise or vibration, it may indicate that the Preload Adjusting Screw requires recalibration. Technicians should consult the engine’s service manual for diagnostic procedures and ensure that all adjustments are made within the specified tolerances.

Maintenance Tips

Regular maintenance of the Preload Adjusting Screw is important for ensuring its longevity and optimal performance. This includes periodic checks to ensure that the screw’s setting has not changed due to engine operation. Lubrication of the screw and its surrounding components, as per the manufacturer’s recommendations, can also help to maintain smooth operation and prevent seizing.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, as well as related technologies. With a history spanning over a century, Cummins is recognized for its innovation, quality, and commitment to customer success. The company’s product range extends beyond engines to include filtration, emissions solutions, and power generation equipment, all designed to meet the needs of a variety of industries.

Conclusion

The Preload Adjusting Screw, part number 4948096, is a critical component in the maintenance and operation of Cummins diesel engines. Its role in adjusting the preload on various engine parts ensures optimal performance and longevity. By understanding and utilizing this part effectively, operators can maintain engine health, extend engine lifespan, and reduce the likelihood of unexpected downtime due to mechanical issues.

-

Singh, D. K. (2024). Dictionary of Mechanical Engineering. Springer Nature.

↩ -

Barton, D. C., & Fieldhouse, J. D. (2009). Automotive Chassis Engineering Powertrain Chassis System and Vehicle Body. Elsevier.

↩ -

Dixon, J. (2010). Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.