This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

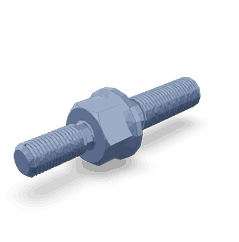

The Studded Flange Cap Screw, Part #4956179, manufactured by Cummins, is a specialized fastener designed for use in heavy-duty trucks. This component is integral to the mechanical systems of these vehicles, ensuring secure and reliable connections in various applications. Cummins, a well-established name in the automotive industry, is recognized for its commitment to quality and innovation, making this part a trusted choice for truck operators and maintenance professionals.

Basic Concepts

A Studded Flange Cap Screw is a type of fastener that includes a threaded stud and a flanged head. The stud is designed to be inserted through holes in the components being joined, while the flange provides a broad surface area for distribution of clamping force. This design allows for a secure and stable connection, essential in the demanding environments of heavy-duty trucks. The Studded Flange Cap Screw functions by threading into a corresponding nut or tapped hole, creating a strong bond between parts 1.

Purpose and Role

The 4956179 Studded Flange Cap Screw plays a significant role in the operation of heavy-duty trucks. It is commonly used in applications where high tensile strength and resistance to vibration are required. This includes securing engine components, transmission parts, and other critical systems where failure is not an option. The screw’s design ensures that it can withstand the rigors of heavy-duty use, providing a reliable connection in these vital areas 2.

Key Features

The 4956179 Studded Flange Cap Screw is crafted from high-quality materials, typically a grade of steel that offers excellent strength and durability. Its design includes a studded section that allows for easy installation and removal, as well as a flanged head that enhances the distribution of clamping force. Unique characteristics such as corrosion resistance and the ability to maintain integrity under high stress conditions further enhance its performance in heavy-duty applications 3.

Benefits

The benefits of using the 4956179 Studded Flange Cap Screw in truck operations are manifold. Its durable construction ensures long-term reliability, reducing the need for frequent replacements. The design of the screw contributes to efficient assembly and disassembly, saving time during maintenance procedures. Additionally, the secure connections it provides help to maintain the integrity of critical systems, contributing to the overall efficiency and safety of the truck.

Installation Process

Proper installation of the 4956179 Studded Flange Cap Screw is vital to ensure its effectiveness. The process involves threading the stud into a pre-tapped hole or corresponding nut, using the appropriate tools to achieve the recommended torque specifications. It is important to follow manufacturer guidelines to avoid over-tightening, which can lead to damage, or under-tightening, which may result in an insecure connection. Careful attention to alignment and the use of thread lubricants can facilitate a smooth installation.

Maintenance and Troubleshooting

Regular maintenance of the 4956179 Studded Flange Cap Screw is recommended to ensure its longevity and optimal performance. This includes periodic checks for signs of wear or corrosion, and tightening as necessary. Troubleshooting common issues such as loosening or damage can often be addressed by re-torquing the screw or, in more severe cases, replacing it. Keeping the screw and surrounding areas clean and free of debris can also prevent issues from arising.

Safety Considerations

When working with the 4956179 Studded Flange Cap Screw, it is important to adhere to safety guidelines. This includes wearing appropriate personal protective equipment, such as gloves and safety glasses, to protect against injury. Ensuring that the truck is securely supported and the engine is off during installation or maintenance procedures is also crucial. Following torque specifications and using the correct tools will help to prevent accidents and ensure a safe working environment.

Cummins Overview

Cummins is a renowned manufacturer in the automotive industry, known for its high-quality components and innovative solutions. With a strong reputation for reliability and performance, Cummins components are a preferred choice for heavy-duty applications. The company’s commitment to quality is evident in their rigorous testing and quality control processes, ensuring that each part, including the 4956179 Studded Flange Cap Screw, meets the high standards required for heavy-duty use.

Studded Flange Cap Screw 4956179 in Cummins Engines

The Studded Flange Cap Screw 4956179, manufactured by Cummins, is a critical component in several of their engine models. This part is essential for securing flanges and ensuring the integrity of the engine’s sealing and structural connections.

GTA38 G CMEICS G116C

In the GTA38 G CMEICS G116C engine, the Studded Flange Cap Screw 4956179 is used to fasten various flanges, maintaining the alignment and seal of critical engine components. Its robust design ensures that the flanges remain tightly secured under operational stresses.

QSK19 CM2350 K105 and QSK19 CM2350 K114

For the QSK19 CM2350 K105 and QSK19 CM2350 K114 engines, the Studded Flange Cap Screw 4956179 plays a pivotal role in securing the flanges that connect the engine’s exhaust and intake systems. This ensures that there are no leaks and that the engine operates efficiently.

QSK19 CM850 MCRS

In the QSK19 CM850 MCRS engine, the Studded Flange Cap Screw 4956179 is used to secure flanges in the engine’s cooling system. Proper fastening of these flanges is crucial for maintaining the engine’s temperature regulation and preventing coolant leaks.

Role of Part 4956179 Studded Flange Cap Screw in Engine Systems

The 4956179 studded flange cap screw is integral to the assembly and functionality of various engine components. It secures the air cleaner to the engine, ensuring a tight seal that prevents air leaks and maintains efficient airflow. This screw also plays a part in attaching the engine oil cover, which is essential for containing oil and protecting internal engine components from contaminants.

In the cam follower cover, the 4956179 screw ensures that the cover is properly sealed, safeguarding the cam followers from debris and ensuring smooth operation of the camshaft. It is also used in the front gear assembly, where it helps maintain the precise alignment and secure fit of the gears, which is vital for the transmission of power within the engine.

The screw is employed in the attachment of the fuel filter, where it ensures that the filter is correctly positioned and sealed, allowing for the efficient filtration of fuel before it reaches the engine. In the fuel harness and electronic control module (ECM) wiring system, the 4956179 screw secures wiring harnesses and modules, ensuring electrical connections remain intact and protected from vibration and environmental factors.

Lastly, in the engine monitoring system, this screw is used to attach sensors and monitoring components, ensuring they are firmly in place and able to provide accurate readings for engine performance and diagnostics. The consistent use of the 4956179 studded flange cap screw across these components highlights its versatility and importance in maintaining the integrity and performance of engine systems.

Conclusion

The 4956179 Studded Flange Cap Screw is a critical component in the maintenance and operation of heavy-duty trucks, particularly in Cummins engines. Its robust design, high-quality materials, and versatile applications make it an essential part for securing various engine components and ensuring the reliability and efficiency of the vehicle. Proper installation, maintenance, and adherence to safety guidelines are crucial for maximizing the performance and longevity of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.