This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Preload Adjusting Screw 4967782 by Cummins is a specialized component designed for use in heavy-duty truck operations. This part plays a significant role in ensuring the proper functioning of various mechanical systems within these vehicles. Understanding its purpose and significance is vital for maintaining the efficiency and reliability of heavy-duty trucks.

Basic Concepts of Preload Adjusting Screws

Preload adjusting screws are mechanical components used to apply a specific amount of preload, or initial tension, to bearings or other rotating elements. This preload helps to maintain proper alignment and reduce the likelihood of excessive wear or failure. In general mechanical systems, these screws are crucial for optimizing performance and longevity 1.

Purpose and Role in Truck Operation

The Preload Adjusting Screw 4967782 is specifically designed to function within the engine or transmission system of heavy-duty trucks. Its role is to ensure that the components within these systems maintain the correct level of preload. This is particularly important in high-stress environments where precision and reliability are paramount. By maintaining the appropriate preload, the screw contributes to the smooth operation and durability of the truck’s mechanical systems 2.

Key Features

The Preload Adjusting Screw 4967782 boasts several key features that enhance its performance. These include a robust material composition designed to withstand high levels of stress and wear. The screw is also engineered with precise design specifications to ensure accurate preload application. Additionally, it may feature unique attributes such as corrosion resistance or ease of adjustment, which further contribute to its effectiveness in heavy-duty applications.

Benefits

Using the Preload Adjusting Screw 4967782 offers several benefits. These include improved efficiency in the mechanical systems it serves, enhanced durability due to its high-quality material and design, and performance enhancements that contribute to the overall reliability of the truck. The screw’s ability to maintain precise preload levels also helps to prevent unnecessary wear and tear on other components, extending their lifespan 3.

Installation Process

Proper installation of the Preload Adjusting Screw 4967782 is crucial for its effective function. The process involves several steps, including preparing the installation site, using the appropriate tools to ensure a secure fit, and following best practices to avoid common installation errors. Detailed instructions should be consulted to ensure that the screw is correctly fitted and functions as intended.

Troubleshooting Common Issues

Common issues with the Preload Adjusting Screw 4967782 may include improper preload levels, wear, or damage to the screw itself. Troubleshooting these problems involves checking the preload settings, inspecting the screw for signs of wear or corrosion, and making necessary adjustments or replacements. Regular monitoring and maintenance can help to identify and address these issues before they lead to more significant problems.

Maintenance Tips

To prolong the lifespan and ensure optimal performance of the Preload Adjusting Screw 4967782, regular maintenance is recommended. This includes periodic checks of the preload levels, cleaning the screw and surrounding components to prevent buildup of dirt or debris, and inspecting for any signs of wear or damage. Following these maintenance practices can help to maintain the efficiency and reliability of the truck’s mechanical systems.

Cummins: A Brief Overview

Cummins Inc. is a well-established manufacturer in the automotive industry, particularly known for its diesel engines and related components. With a rich history of innovation and a diverse product range, Cummins has built a reputation for quality and reliability. The company’s commitment to excellence is evident in its offerings, including the Preload Adjusting Screw 4967782, which exemplifies Cummins’ dedication to providing high-performance solutions for heavy-duty applications.

Cummins Part 4967782 Preload Adjusting Screw Compatibility

The Cummins part 4967782, a Preload Adjusting Screw, is designed to fit seamlessly with a range of Cummins engines, ensuring optimal performance and reliability. This part is integral to the maintenance and adjustment of engine components, particularly in the context of preload settings.

K19 Series Engines

The K19 series engines, including the K19 CM2350 K114 and K19 CM2350 K144G, benefit from the precise adjustments provided by the 4967782 Preload Adjusting Screw. This part is essential for maintaining the correct preload on various engine components, ensuring smooth operation and longevity.

QSK19 Series Engines

For the QSK19 series engines, the 4967782 Preload Adjusting Screw is compatible with the QSK19 CM500, QSK19 CM850 MCRS, and QSK19G models. This screw plays a crucial role in adjusting the preload on the engine’s components, which is vital for the engine’s performance and durability.

QST30 Series Engines

The QST30 CM552 engine also utilizes the 4967782 Preload Adjusting Screw. This part is essential for fine-tuning the preload settings, ensuring that the engine operates at peak efficiency and reliability.

By ensuring that the preload is correctly set, the 4967782 Preload Adjusting Screw helps to maintain the integrity of the engine’s components, reducing wear and tear and extending the engine’s lifespan.

Role of Part 4967782 Preload Adjusting Screw in Engine Systems

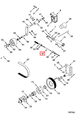

The Part 4967782 Preload Adjusting Screw is an essential component in maintaining the optimal performance of various engine systems. Its primary function is to ensure precise adjustments within the mechanical assemblies it is integrated into.

In the Belt Tensioner system, the Preload Adjusting Screw allows for fine-tuning the tension of the drive belt. This ensures that the belt operates within the specified parameters, reducing wear and tear, and enhancing the efficiency of power transmission to auxiliary components such as the alternator and water pump.

Within the Fan Drive mechanism, the screw plays a significant role in adjusting the preload, which directly influences the engagement and disengagement of the fan clutch. Proper preload ensures that the fan operates efficiently under varying engine loads, contributing to optimal cooling performance and reduced parasitic losses.

The Fan Drive Idle Assembly benefits from the precise adjustments afforded by the Preload Adjusting Screw. By fine-tuning the preload, engineers and mechanics can ensure that the fan operates smoothly during idle conditions, minimizing noise and vibration while maintaining adequate cooling.

Similarly, in the Fan Drive Idler Assembly, the screw’s role is to maintain the correct tension and alignment of the idler components. This is vital for the seamless operation of the fan drive system, ensuring that the fan engages and disengages as needed without undue stress on the system.

Lastly, in the Mounting of various engine components, the Preload Adjusting Screw helps in securing and aligning parts with high precision. This is particularly important in ensuring that all moving parts within the engine system operate harmoniously, reducing the likelihood of mechanical failures and enhancing overall engine reliability.

Conclusion

The Preload Adjusting Screw 4967782 by Cummins is a critical component in the maintenance and optimal performance of heavy-duty truck engines. Its role in ensuring precise preload adjustments across various engine systems contributes significantly to the efficiency, durability, and reliability of these vehicles. Proper installation, regular maintenance, and timely troubleshooting of this part are essential practices for maximizing its benefits and ensuring the longevity of the truck’s mechanical systems.

-

Daniel Williams, Generalized Vehicle Dynamics, SAE International, 2022.

↩ -

Haoran Hu, Simon J Baseley, and Xubin Song, Advanced Hybrid Powertrains for Commercial Vehicles Second Edition, SAE International, 2021.

↩ -

Robert Fischer, Ferit Kucukay, Gunter Jurgens, Rolf Najork, and Burkhard Pollak, The Automotive Transmission Book Powertrain, Springer, 2015.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.