This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

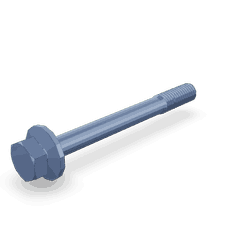

The 4974049 Captive Washer Cap Screw, manufactured by Cummins, is a specialized fastener designed for use in commercial truck maintenance and operation. Cummins, a well-established name in the commercial vehicle industry, produces a range of components that contribute to the efficiency and reliability of heavy-duty trucks. This Cummins part plays a significant role in the assembly and maintenance of these vehicles.

Basic Concepts of Captive Washer Cap Screws

A Captive Washer Cap Screw is a type of fastener that includes an integrated washer held captive on the screw’s shank. This design ensures that the washer remains in place during installation, eliminating the need for separate washer handling and reducing the risk of washer loss. Captive Washer Cap Screws are commonly used in mechanical assemblies where consistent and secure fastening is required. They are particularly beneficial in environments where access to the fastening area is limited or where the loss of washers could lead to operational issues 1.

Purpose of the 4974049 Captive Washer Cap Screw in Truck Operation

In the context of commercial truck operation, the 4974049 Captive Washer Cap Screw serves to secure various components, contributing to the structural integrity of the vehicle. It is often used in applications where vibration and dynamic loads are present, ensuring that parts remain firmly attached under varying conditions. By providing a reliable fastening solution, this screw helps maintain the operational safety and efficiency of the truck 2.

Key Features of the 4974049 Captive Washer Cap Screw

The 4974049 Captive Washer Cap Screw is engineered with specific design elements and material properties to meet the demands of heavy-duty applications. Its integrated washer is a key feature, offering consistent distribution of clamping force and protection against surface damage. The screw’s thread design is optimized for easy installation and removal, while its material durability ensures resistance to corrosion and wear, making it suitable for the harsh environments typical of commercial truck operations 3.

Benefits of Using the 4974049 Captive Washer Cap Screw

The use of the 4974049 Captive Washer Cap Screw offers several advantages. It streamlines the assembly process by eliminating the need for separate washers, which can be particularly beneficial in high-volume production or maintenance scenarios. Additionally, the captive washer design reduces the likelihood of washer loss during installation, enhancing the overall efficiency and reliability of the fastening process. The secure fastening provided by this screw contributes to the longevity and performance of the assembled components 4.

Installation Guidelines for the 4974049 Captive Washer Cap Screw

Proper installation of the 4974049 Captive Washer Cap Screw is vital to ensure optimal performance and longevity. It should be installed using the correct torque specifications to achieve the desired clamping force without over-tightening, which could lead to damage. The use of appropriate tools, such as torque wrenches, is recommended to maintain the integrity of the screw and the components being fastened. Careful alignment during installation will also help prevent cross-threading and ensure a secure fit.

Troubleshooting Common Issues with Captive Washer Cap Screws

Captive Washer Cap Screws, including the 4974049, may encounter issues such as loosening due to vibration or corrosion over time. Regular inspection and maintenance can help identify these problems early. If loosening is detected, re-tightening to the specified torque may resolve the issue. In cases of corrosion, cleaning the affected area and applying a suitable anti-corrosive treatment can prevent further degradation. Replacement may be necessary if the screw shows significant wear or damage.

Maintenance Tips for the 4974049 Captive Washer Cap Screw

To prolong the life of the 4974049 Captive Washer Cap Screw and maintain its effectiveness, regular inspection and care are recommended. This includes checking for signs of wear, corrosion, or loosening during routine maintenance checks. Applying a protective coating or lubricant, where appropriate, can enhance the screw’s resistance to environmental factors. Ensuring that all fasteners are tightened to the manufacturer’s specifications during maintenance procedures will also contribute to the screw’s longevity and performance.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration systems, and related technologies. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the commercial vehicle industry. The company’s commitment to advancing technology and meeting the needs of its customers is reflected in its diverse product range and the high standards of its components, such as the 4974049 Captive Washer Cap Screw.

Role of Part 4974049 Captive Washer Cap Screw in Engine Systems

The 4974049 captive washer cap screw is a critical component in the secure assembly of various engine systems. Its primary function is to provide a reliable fastening solution that ensures components remain firmly in place under operational conditions.

Arrangement of Engine Components

In the arrangement of engine components, the 4974049 captive washer cap screw plays a significant role. It is commonly used to fasten brackets, mounts, and other structural elements that support critical engine parts. By securing these components, it helps maintain the precise alignment and spacing required for optimal engine performance. This is particularly important in high-vibration environments where loose components can lead to misalignment and subsequent mechanical failures.

Lifting Mechanisms

When it comes to lifting mechanisms within engine systems, the 4974049 captive washer cap screw ensures that lifting points and attachment points are securely fastened. This is vital for the integrity of the lifting process, whether for maintenance, repair, or transportation of engine components. The captive washer feature of the screw prevents the washer from being lost during installation, which enhances the overall reliability and safety of the lifting operation.

In both arrangement and lifting applications, the 4974049 captive washer cap screw contributes to the stability and durability of engine systems, ensuring that all components function as intended under various operational stresses.

Conclusion

The 4974049 Captive Washer Cap Screw is a vital component in the maintenance and operation of commercial trucks and Cummins engines. Its design, featuring an integrated washer, ensures secure and reliable fastening, which is crucial for the structural integrity and performance of heavy-duty vehicles. Proper installation, regular maintenance, and understanding its role in engine systems are key to maximizing the effectiveness and longevity of this Cummins part.

-

Giles, T. (2019). Automotive Engines Diagnosis Repair and Rebuilding. Cengage Learning.

↩ -

Hiereth, H., Prenninger, P., & Drexl, K. W. (2010). Charging the Internal Combustion Engine. Springer.

↩ -

Huzij, R., Spano, A., & Bennett, S. (2014). Modern Diesel Technology Heavy Equipment Systems. Delmar Cengage Learning.

↩ -

Nunney, M. J. (2007). Light and Heavy Vehicle Technology, Fourth Edition. Butterworth-Heinemann.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.