4982305

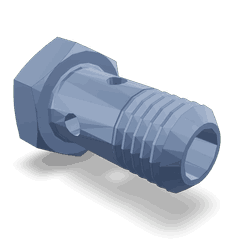

Banjo Connector Screw

Cummins®

IN STOCK

7 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 4982305 Banjo Connector Screw, manufactured by Cummins, is a component used in commercial trucks. It serves a specific function within the truck’s system, facilitating the connection between various fluid lines and components. This part is integral to maintaining the integrity and efficiency of the truck’s fluid systems.

Basic Concepts of Banjo Connector Screws

A banjo connector screw is a type of fitting used in fluid systems to connect hoses or pipes to components such as filters, pumps, or valves. It typically consists of a bolt with a banjo fitting attached, which has a hollow body and two bolt holes. When tightened, the banjo connector screw compresses a gasket or O-ring, creating a seal that prevents fluid leaks. The design allows for easy connection and disconnection of fluid lines, making it a popular choice in automotive and industrial applications 1.

Purpose of the 4982305 Banjo Connector Screw

This Cummins part plays a role in the operation of a truck by connecting specific fluid systems and managing the flow of fluids between components. It is commonly used in hydraulic and fuel systems, where it ensures a secure and leak-proof connection. The screw helps maintain the pressure and flow necessary for the proper functioning of these systems 2.

Key Features

The 4982305 is designed with several features that enhance its performance and durability. It is constructed from high-quality materials, typically steel or stainless steel, which provide strength and resistance to corrosion. The screw features a specific thread type that ensures a secure fit and proper sealing. Additionally, it may include unique attributes such as a hex head for easy tightening or a built-in gasket for enhanced sealing capabilities 3.

Benefits of Using the 4982305 Banjo Connector Screw

Incorporating this part into truck systems offers several advantages. Its reliable design ensures a secure connection, reducing the risk of leaks and maintaining system efficiency. The screw is easy to install, with straightforward threading and sealing methods. It is also compatible with a wide range of components, making it a versatile choice for various applications.

Installation Process

Proper installation of the 4982305 involves several steps to ensure a secure and leak-proof connection. Begin by cleaning the mating surfaces to remove any debris or contaminants. Apply a suitable sealant to the threads if required, following the manufacturer’s recommendations. Insert the screw into the banjo fitting and align it with the component. Tighten the screw to the specified torque using a torque wrench to avoid over-tightening, which could damage the fitting or gasket. Finally, inspect the connection for leaks and make any necessary adjustments.

Troubleshooting Common Issues

Common problems associated with banjo connector screws include leaks, thread damage, and connection integrity issues. To troubleshoot leaks, inspect the gasket or O-ring for wear or damage and replace it if necessary. Ensure the screw is tightened to the correct torque to prevent over-tightening, which can cause thread damage. If the connection appears loose, re-tighten the screw and check for proper alignment. In cases of severe thread damage, the screw or fitting may need to be replaced.

Maintenance Tips

Regular maintenance of the 4982305 is important to ensure longevity and optimal performance. Inspect the screw and connection periodically for signs of wear, corrosion, or leaks. Clean the screw and mating surfaces as needed to remove dirt and debris. Replace the gasket or O-ring according to the manufacturer’s recommendations or if it shows signs of wear. Following these maintenance tips will help maintain the integrity and efficiency of the fluid system.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for quality, innovation, and reliability. The company is committed to advancing technology and providing solutions that meet the evolving needs of its customers. Cummins’ extensive product range includes engines, powertrains, and components designed to enhance the performance and efficiency of commercial vehicles.

Cummins Banjo Connector Screw 4982305 in Engine Applications

The Cummins Banjo Connector Screw, part number 4982305, is a critical component in the fuel and hydraulic systems of various engines. This part is designed to secure the banjo fitting, ensuring a tight seal and preventing leaks in high-pressure systems.

B3.3 Engines

In B3.3 engines, the 4982305 is utilized in the fuel delivery system. It ensures that the connections between the fuel lines and the injectors are secure, maintaining the integrity of the fuel system and preventing any fuel leaks that could compromise engine performance.

ISB5.9 CM2880 B110 and QSB5.9 CM2880 B115 Engines

For the ISB5.9 CM2880 B110 and QSB5.9 CM2880 B115 engines, the 4982305 plays a vital role in both the fuel and hydraulic systems. In the fuel system, it secures the connections to the injectors, ensuring that the fuel delivery is consistent and reliable. In the hydraulic system, it is used to secure connections to various hydraulic lines, maintaining the system’s pressure and preventing leaks that could affect the engine’s hydraulic functions.

The use of the 4982305 in these engines highlights its importance in maintaining the performance and reliability of both fuel and hydraulic systems. Its design ensures that the connections remain tight and secure, even under the high pressures and stresses encountered in these engines.

Role of Part 4982305 Banjo Connector Screw in Fuel System Components

The 4982305 is integral to the secure and efficient operation of various fuel system components. In fuel filter plumbing, this component ensures a tight seal between the fuel lines and the filter housing, preventing leaks and maintaining consistent fuel pressure.

Within the broader plumbing system, the Banjo Connector Screw facilitates the connection between different sections of fuel lines, enhancing the overall integrity of the fuel delivery system.

When specifically applied to fuel lines, this screw plays a significant role in maintaining the structural stability of the connections, which is essential for the safe and reliable transport of fuel from the tank to the engine.

Additionally, in the context of fuel filter connections, the Banjo Connector Screw ensures that the filter is properly sealed, allowing for effective filtration without the risk of fuel bypassing the filter or leaking from the connection points.

This component’s reliable performance is fundamental to the efficient and safe operation of the entire fuel system.

Conclusion

The 4982305 Banjo Connector Screw is a vital component in the fluid systems of commercial trucks, ensuring secure and leak-proof connections in both fuel and hydraulic systems. Its robust design, ease of installation, and compatibility with various components make it a reliable choice for maintaining the efficiency and performance of truck systems. Regular maintenance and proper installation are key to maximizing the longevity and effectiveness of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.