4996922

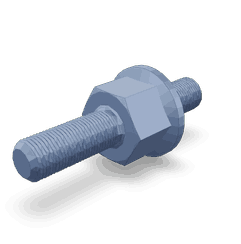

Studded Flange Cap Screw

Cummins®

IN STOCK

1 is currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Studded Flange Cap Screw, Part #4996922, manufactured by Cummins, is a specialized fastener designed for heavy-duty truck applications. Cummins, a renowned name in the automotive and heavy-duty truck industry, ensures that this component meets the rigorous demands of truck mechanics and operations. This screw is integral to the structural integrity and functionality of various truck components, highlighting Cummins’ commitment to quality and reliability.

Basic Concepts

A Studded Flange Cap Screw is a type of fastener that includes a threaded stud and a flanged head. The stud is designed to be inserted through holes in components and secured with a nut, while the flange provides additional surface area for torque application, enhancing the screw’s holding power. In a truck’s mechanical system, these screws are used to secure components that require strong, durable fastening solutions 1.

Purpose and Role in Truck Operation

This Cummins part plays a significant role in the operation of heavy-duty trucks by securing critical components that are subject to high stress and vibration. Its application areas include engine mounts, transmission housings, and other structural elements where reliable fastening is paramount. The screw contributes to maintaining the structural integrity and functionality of these components, ensuring the truck operates efficiently and safely 2.

Key Features

The 4996922 is characterized by several key features that enhance its performance and durability. It is made from high-strength materials, ensuring it can withstand the demanding conditions of heavy-duty truck applications. The design includes a flanged head that provides a larger surface area for torque application, improving the screw’s holding power. Additionally, the screw’s studded design allows for easy installation and removal, facilitating maintenance and repair processes.

Benefits

Using this part offers several advantages. Its robust construction and design contribute to improved reliability, reducing the likelihood of fastener failure under stress. The ease of installation, facilitated by the studded design, can lead to potential cost savings in labor during maintenance and repair operations. Furthermore, the screw’s durability ensures long-term performance, minimizing the need for frequent replacements.

Installation and Usage

Proper installation of the Studded Flange Cap Screw is crucial for ensuring optimal performance. It is recommended to follow manufacturer guidelines for torque settings to achieve the correct tension without over-tightening, which could damage the screw or the components being fastened. Special considerations should include ensuring the surfaces are clean and free of debris before installation to prevent corrosion and ensure a secure fit 3.

Troubleshooting and Maintenance

Common issues with the Studded Flange Cap Screw may include loosening over time due to vibration or corrosion. Regular inspections can help identify these issues early. Troubleshooting tips include checking for proper torque settings and ensuring that all surfaces are clean and free of contaminants. Maintenance practices such as applying an anti-seize compound can prolong the screw’s lifespan and ensure continued reliable operation.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the automotive and heavy-duty truck industry. The company’s extensive product range and commitment to excellence provide a solid foundation for the quality and reliability of the 4996922 Studded Flange Cap Screw.

Compatibility with Cummins Engines

This part is designed to fit a variety of Cummins engines. It is essential for securing flanges and ensuring a tight seal, which is crucial for the proper functioning of the engine’s components. Below is a detailed look at the compatibility of this part with various Cummins engines:

- 15N CM2380 M104B, D4.0 CM2620 D103B: Ensures secure fastening of flanges in the engine’s exhaust and intake systems.

- F3.8 CM2350 F128C, F3.8 CM2620 F137B, F4.5 CM2620 F139B: Withstands high pressures and temperatures within the engine, providing a reliable connection for flanges in the exhaust and intake manifolds.

- ISB (Chrysler), ISB6.7 CM2350 B101, ISB6.7 G CM2180 B118: Ensures that flanges are securely fastened, contributing to the engine’s overall efficiency and longevity.

- ISG12 CM2880 G107, ISL9 CM2150 SN, L9 CM2670 L128B: Provides a strong grip, which is essential for maintaining the structural integrity of the engine components.

- QSB4.5 CM2250 EC, QSB6.7 CM2250: Ensures that flanges are securely fastened in the exhaust and intake systems, crucial for maintaining the engine’s performance and preventing leaks.

- QSF3.8 CM2350 F107, QSG12/X12 CM2350 G110, QSL8.9 CM2150 L141, QSL9 CM850 (CM2850): Ensures that flanges are securely fastened, which is essential for maintaining the engine’s sealing and preventing leaks.

Role of Part 4996922 in Engine Systems

The Studded Flange Cap Screw is integral to the secure assembly and operation of various engine components. It ensures reliable connections and maintains the integrity of the engine system.

Air Intake Connection

In the air intake system, this part secures the connection between the air intake device and the engine. This connection is vital for maintaining the proper airflow into the engine, which is essential for optimal combustion and performance.

Noise Reduction

The screw is also used in components designed for noise reduction. By securely fastening noise reduction devices, it helps in maintaining the structural integrity of these components, ensuring they function effectively to reduce engine noise.

Gauge and Oil Level Monitoring

In systems involving gauges for oil level monitoring, the screw plays a role in securing the gauge to the engine. This ensures accurate readings and reliable monitoring of the oil level, which is important for engine health and performance.

Harness and Wiring Connections

For electronic control module (ECM) wiring harnesses and engine control wiring, the screw is used to secure connections. This is important for maintaining the integrity of the electrical connections, ensuring reliable communication between the ECM and various engine components.

Engine Control Module

In the engine control module, the screw helps in securing the module to the engine or its mounting bracket. This ensures that the ECM remains stable and securely connected, which is essential for its accurate operation and data processing.

Plumbing and Turbocharger

In plumbing applications within the engine system, such as those involving the turbocharger, the screw is used to secure connections. This is important for maintaining the integrity of the plumbing system, ensuring proper fluid flow and pressure within the engine.

Conclusion

The 4996922 Studded Flange Cap Screw is a critical component in the maintenance and operation of heavy-duty trucks and Cummins engines. Its robust design, ease of installation, and compatibility with a wide range of Cummins engines make it an essential part for ensuring the reliability and efficiency of truck and engine systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.