5261712

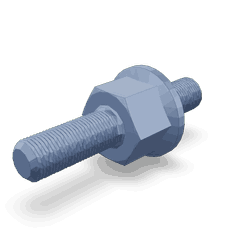

Studded Flange Cap Screw

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 5261712 Studded Flange Cap Screw by Cummins is a specialized fastener designed for heavy-duty truck applications. Its purpose is to provide secure and reliable fastening in various truck systems, ensuring components remain firmly in place under demanding conditions. The significance of this part lies in its ability to enhance the durability and reliability of truck operations, contributing to overall vehicle performance and longevity.

Basic Concepts

A Studded Flange Cap Screw is a type of fastener that includes a threaded stud and a flanged head. The stud is designed to be inserted through holes in components and secured with a nut, while the flanged head provides additional stability and prevents the screw from pulling through the material. In the context of heavy-duty trucks, these screws are used to fasten critical components, ensuring they remain securely attached despite the rigors of heavy-duty use.

Purpose and Role in Truck Operation

The 5261712 Studded Flange Cap Screw plays a role in the operation of a truck by securing various components within the vehicle’s systems. It is commonly used in applications such as engine mounts, exhaust systems, and chassis components. By providing a strong and stable connection, this screw helps maintain the integrity of these systems, ensuring they function correctly and withstand the stresses of heavy-duty use.

Key Features

The 5261712 Studded Flange Cap Screw features a robust design that includes a high-strength material composition, typically alloy steel, which offers excellent resistance to wear and corrosion. The flanged head design enhances stability and prevents the screw from pulling through the material. Additionally, the screw is engineered with precise threading to ensure a secure fit and easy installation.

Benefits

The benefits of using the 5261712 Studded Flange Cap Screw include improved durability, reliability, and efficiency in truck operations. Its high-strength material composition ensures it can withstand the demanding conditions of heavy-duty use, while its design enhances the stability of fastened components. This results in reduced maintenance requirements and increased overall vehicle performance.

Installation Process

Proper installation of the 5261712 Studded Flange Cap Screw involves several steps to ensure a secure fit. Begin by aligning the screw with the designated holes in the components. Insert the stud through the holes and secure it with a nut, ensuring it is tightened to the manufacturer’s specified torque settings. Use appropriate tools, such as a torque wrench, to achieve the correct tightness without over-tightening, which could damage the screw or the components.

Troubleshooting and Maintenance

Common issues with the 5261712 Studded Flange Cap Screw may include loosening over time due to vibration or corrosion. Regular inspection and maintenance can help identify and address these issues. If loosening is detected, re-tighten the screw to the specified torque settings. Additionally, applying a thread locker can help prevent future loosening. To prolong the lifespan of the screw, ensure it is protected from corrosion by applying a suitable coating or sealant.

Safety Considerations

When working with the 5261712 Studded Flange Cap Screw, it is important to follow proper handling procedures to ensure safety. Wear appropriate personal protective equipment, such as gloves and safety glasses, to protect against injury. Be aware of potential hazards, such as sharp edges or high torque settings that could cause the screw to strip or break. Always follow the manufacturer’s guidelines for installation and maintenance to avoid accidents.

Cummins Overview

Cummins is a renowned manufacturer with a long-standing reputation in the industry for producing high-quality truck components. The company is committed to innovation and excellence, consistently delivering products that meet the demanding requirements of heavy-duty applications. Cummins’ dedication to quality and performance ensures that their components, including the 5261712 Studded Flange Cap Screw, are reliable and effective in enhancing truck operations.

Compatibility with Cummins Engines

The Studded Flange Cap Screw, part number 5261712, manufactured by Cummins, is a critical component used in various Cummins engine models. This part is essential for securing flanges and ensuring a tight seal, which is crucial for the engine’s operational integrity. Below is a detailed overview of the engines with which this part is compatible:

ISC Series Engines

- ISC CM2150

- ISC CM850

- ISC8.3 CM2250

ISL Series Engines

- ISL CM2150

- ISL G CM2180

- ISL9 CM2150 SN

- ISL9 CM2250

- ISL9.5 CM2880 L138

L Series Engines

- L GAS PLUS CM556

- L8.9

- L8.9 CM2670 L134C

- L8.9 L121

- L8.9G CMOH2.0 L125B

- L9 CM2670 L128B

- L9.3 L105

QSC and QSL Series Engines

- QSC8.3 CM2880 C102

- QSC8.3 CM850 (CM2850)

- QSC9 CM2250 / QSL9 CM2250

- QSL8.9 CM2150 L141

- QSL9 CM2250

- QSL9 CM2350 L102

- QSL9 CM850 (CM2850)

- QSL9.3 CM2880 L113

The Studded Flange Cap Screw is a versatile component that ensures the secure attachment of flanges across a wide range of Cummins engines, contributing to the overall efficiency and durability of these engines.

Role of Part 5261712 Studded Flange Cap Screw in Engine Systems

The 5261712 studded flange cap screw is an essential component in securing various elements within engine systems. Its primary function is to provide a robust and reliable fastening mechanism that ensures the integrity and stability of the engine’s components.

Securing the Cover

In engine systems, the cover serves as a protective enclosure for internal components. The 5261712 studded flange cap screw plays a significant role in fastening the cover securely in place. This ensures that the cover remains tightly sealed, preventing any unauthorized access or accidental dislodgment during engine operation. The screw’s design allows for easy installation and removal, facilitating maintenance and inspection procedures.

Front Gear Assembly

The front gear is a vital component in the engine’s transmission system, responsible for transferring power from the engine to other parts of the machinery. The 5261712 studded flange cap screw is utilized to secure the front gear in its designated position. This fastening ensures that the gear remains aligned and stable, contributing to the smooth and efficient transfer of power. The screw’s studded flange provides additional surface area for a more secure grip, reducing the risk of gear misalignment or failure.

Gauge and Oil Level Monitoring

Accurate monitoring of the engine’s oil level is essential for maintaining optimal performance and preventing damage. The 5261712 studded flange cap screw is employed to secure gauges and sensors responsible for oil level measurement. By providing a stable and reliable fastening solution, the screw ensures that these components remain in their correct positions, allowing for precise and consistent oil level readings. This, in turn, enables engineers and mechanics to make informed decisions regarding oil changes and maintenance schedules.

Mounting and Gear Cover Integration

The mounting of various engine components is a complex process that requires precise alignment and secure fastening. The 5261712 studded flange cap screw is instrumental in mounting components such as the gear cover. The gear cover protects the internal gears and other sensitive parts of the engine. The screw’s design allows for a strong and durable connection, ensuring that the gear cover remains firmly in place during engine operation. This not only protects the internal components but also contributes to the overall stability and performance of the engine.

Conclusion

In summary, the 5261712 studded flange cap screw is a versatile and reliable fastening solution that plays a significant role in securing various components within engine systems. Its application in covering, front gear assembly, gauge and oil level monitoring, and mounting and gear cover integration demonstrates its importance in maintaining the integrity and performance of engine systems.

References

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.