This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

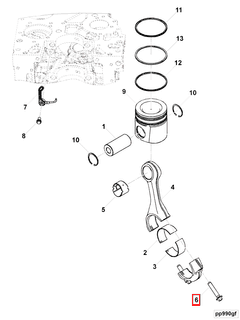

Connecting rod cap screws are vital components in the operation of heavy-duty truck engines, ensuring the secure attachment of the connecting rod to the crankshaft. This discussion focuses on the 5263944 connecting rod cap screw by Cummins, exploring its function, design, and benefits within the context of heavy-duty truck engines.

Basic Concepts of Connecting Rod Cap Screws

Connecting rod cap screws are designed to fasten the connecting rod to the crankshaft in an internal combustion engine. This connection is crucial for transmitting the force generated by the combustion process from the piston to the crankshaft, converting linear motion into rotational motion. The integrity of this connection directly influences the engine’s efficiency and reliability 1.

Role of the 5263944 Connecting Rod Cap Screw in Truck Engines

The 5263944 connecting rod cap screw by Cummins is engineered to maintain the structural integrity of the connecting rod-crankshaft assembly in heavy-duty truck engines. By securely fastening the connecting rod cap to the rod, it ensures that the forces exerted during engine operation are effectively transmitted to the crankshaft. This screw’s design and material properties are tailored to withstand the high stresses and temperatures encountered in heavy-duty applications 2.

Key Features of the 5263944 Connecting Rod Cap Screw

The 5263944 connecting rod cap screw boasts several design and material characteristics that enhance its performance and durability. Crafted from high-strength materials, it offers superior resistance to wear and fatigue. Its precise threading and torque specifications ensure a secure and consistent connection, minimizing the risk of loosening under engine stress. Additionally, the screw’s design may include features such as locking mechanisms to prevent unintended loosening, further enhancing engine reliability 3.

Benefits of Using the 5263944 Connecting Rod Cap Screw

Utilizing the 5263944 connecting rod cap screw in heavy-duty truck engines provides several advantages. Its robust construction and precise engineering contribute to improved engine reliability, allowing for consistent performance under demanding conditions. The screw’s durability extends the service life of the engine components, reducing the need for frequent replacements and maintenance. Furthermore, the enhanced connection it provides can lead to more efficient power transmission, potentially improving overall engine performance 4.

Troubleshooting and Maintenance

Common issues associated with connecting rod cap screws include loosening, wear, and failure due to fatigue or improper installation. Symptoms of these issues may include unusual engine noises, decreased performance, or visible damage to the screw or surrounding components. Regular maintenance, including torque checks and inspections for signs of wear or damage, is recommended to ensure optimal performance. Proper installation techniques, such as using the correct torque specifications and ensuring the screw is free from contaminants, are crucial for maintaining the integrity of the connecting rod-crankshaft assembly 5.

Compatibility of Connecting Rod Cap Screw Part 5263944 with Cummins Engines

The Connecting Rod Cap Screw part number 5263944, manufactured by Cummins, is designed to fit a variety of Cummins engines. This screw is a critical component in securing the connecting rod cap to the connecting rod, ensuring the stability and efficiency of the engine’s operation.

F2.8 CM2620 F135B

The part 5263944 is compatible with the F2.8 CM2620 F135B engine. This engine variant is known for its robust design and reliability, making the screw an essential part of its assembly.

ISF2.8 CM2220 F117, ISF2.8 CM2220 F129

The ISF2.8 CM2220 F117 and ISF2.8 CM2220 F129 engines also utilize the 5263944 Connecting Rod Cap Screw. These engines are part of the ISF series, which is recognized for its durability and efficiency in various applications.

QSF2.8 CM2880 F104, QSF2.8 CM2880 F105, QSF2.8 CM2880 F108, QSF2.8 CM2880 F114

The QSF2.8 CM2880 series engines, including the F104, F105, F108, and F114 variants, are designed for high-performance applications. The 5263944 screw is integral to these engines, ensuring the connecting rod cap remains securely fastened under high stress conditions.

R2.8 CM2220 R101B

Lastly, the R2.8 CM2220 R101B engine is another model that benefits from the use of the 5263944 Connecting Rod Cap Screw. This engine is engineered for reliability and efficiency, making the screw a key component in its assembly and operation.

Understanding the Role of Part 5263944 Connecting Rod Cap Screw in Engine Systems

In the intricate dance of an internal combustion engine, the Connecting Rod Cap Screw (part 5263944) plays a significant role in maintaining the structural integrity and operational efficiency of several key components.

Integration with the Connecting Rod and Piston

The connecting rod cap screw is essential in securing the connecting rod to the piston. This connection is vital as it transmits the force generated by the combustion process from the piston to the crankshaft. The screw ensures that the connecting rod remains firmly attached to the piston, allowing for smooth and consistent power transfer.

Function within the Engine Connecting Rod

As part of the engine connecting rod assembly, the connecting rod cap screw helps to maintain the alignment and balance of the rod. This is particularly important during the high-speed rotation of the crankshaft, where even minor misalignments can lead to increased wear, reduced efficiency, and potential engine damage. The screw’s precise fit and secure hold contribute to the overall durability and performance of the connecting rod.

Interaction with the Piston

The relationship between the connecting rod cap screw and the piston is foundational to the engine’s operation. By ensuring a tight and reliable connection, the screw helps to prevent piston slap—a condition where the piston rocks within the cylinder, leading to noise, increased friction, and potential damage. This secure attachment is essential for maintaining the piston’s optimal movement within the cylinder, enhancing engine performance and longevity.

Role in the Overall Engine System

In the broader context of the engine system, the connecting rod cap screw is a small yet indispensable component. Its role in securing the connecting rod to the piston ensures that the engine’s moving parts operate in harmony. This contributes to the engine’s overall efficiency, power output, and reliability. The screw’s ability to withstand high stresses and temperatures is a testament to its importance in the engine’s complex mechanism.

Conclusion

The 5263944 connecting rod cap screw by Cummins is a critical component in the operation of heavy-duty truck engines. Its robust design, precise engineering, and compatibility with various Cummins engines make it an essential part for maintaining engine reliability and performance. Regular maintenance and proper installation techniques are crucial for ensuring the longevity and efficiency of this component.

-

Huzij, R., Spano, A., & Bennett, S. (2014). Modern Diesel Technology Heavy Equipment Systems. Delmar Cengage Learning.

↩ -

Quigley, J. M. (2023). SAE International’s Dictionary of Testing, Verification and Validation. SAE International.

↩ -

SAE International. (2013). Composite Materials Handbook Volume 4 Metal Matrix Composites. SAE International.

↩ -

Hu, H., Smaling, R., & Baseley, S. (2014). Heavy-Duty Wheeled Vehicles. SAE International.

↩ -

Cummins Inc. (n.d.). Company Overview. Retrieved from Cummins Official Website.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.