This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

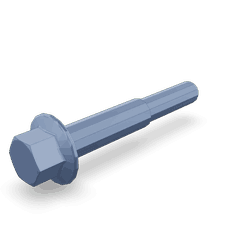

The Hexagon Flange Head Cap Screw, identified by part number 5268870, is a component manufactured by Cummins, a well-established name in the automotive industry. This screw plays a significant role in the maintenance and operation of commercial trucks. Its design and functionality are tailored to meet the demanding requirements of heavy-duty applications 4.

Basic Concepts

A Hexagon Flange Head Cap Screw is a type of fastener characterized by its hexagonal head and a flange beneath the head. The hexagonal head allows for efficient torque application using common hand tools, while the flange provides additional surface area to distribute the load and prevent the screw from sinking into the material 1. In the context of truck components, this screw is used to secure various parts, ensuring they remain firmly in place under operational stress.

Purpose and Role in Truck Operation

The 5268870 Hexagon Flange Head Cap Screw is designed to secure components within a truck’s structure. It is commonly used in applications where a high degree of fastening strength and resistance to loosening is required. This includes securing engine components, chassis parts, and other critical assemblies. Its role is to maintain the integrity of these connections, ensuring the truck operates safely and efficiently 2.

Key Features

The 5268870 Hexagon Flange Head Cap Screw features a hexagonal head that facilitates easy and precise tightening with standard tools. The flange beneath the head enhances the screw’s ability to distribute load and resist sinking into softer materials. Additionally, the screw is made from high-quality materials that offer excellent durability and resistance to corrosion, making it suitable for the harsh environments often encountered in commercial trucking 3.

Benefits

This screw provides several benefits, including enhanced durability due to its material properties. The hexagonal head design allows for improved torque application, ensuring secure fastening. Furthermore, the flange feature contributes to resistance against loosening, which is crucial in dynamic and vibrating environments like those found in truck operations.

Installation Guidelines

Proper installation of the 5268870 Hexagon Flange Head Cap Screw involves several steps to ensure optimal performance. Begin by cleaning the installation surface to remove any debris or contaminants. Use a torque wrench to apply the specified torque, ensuring the screw is tightened to the manufacturer’s recommendations. It is also advisable to periodically check the tightness of the screw, especially after the initial installation, to prevent any loosening over time.

Troubleshooting and Maintenance

Common issues with the 5268870 Hexagon Flange Head Cap Screw may include loosening or corrosion. To address loosening, re-tighten the screw to the specified torque. If corrosion is observed, clean the affected area and consider applying a corrosion-resistant coating to prevent further degradation. Regular inspections and maintenance can help ensure the longevity and performance of the screw.

Cummins: Manufacturer Overview

Cummins is a renowned manufacturer in the automotive industry, known for its commitment to quality and innovation. With a rich history of producing reliable and high-performance components, Cummins has established a strong reputation for excellence. Their focus on research and development ensures that their products, including the 5268870 Hexagon Flange Head Cap Screw, meet the rigorous demands of commercial trucking applications 4.

Cummins Engine Compatibility with Hexagon Flange Head Cap Screw Part 5268870

The Cummins part 5268870, a Hexagon Flange Head Cap Screw, is designed to fit a variety of Cummins engines. This screw is integral in securing various components within the engine assembly, ensuring structural integrity and operational efficiency. Below is a detailed description of its compatibility across different engine models.

B4.5 CM2350 Series

The B4.5 CM2350 engines, including the B4.5 CM2350 B129B and ISB4.5 CM2350 B104, utilize the Hexagon Flange Head Cap Screw part 5268870 for securing critical components. This screw is essential in maintaining the alignment and stability of the engine’s internal parts.

F3.8 CM2350 Series

The F3.8 CM2350 engines, such as the F3.8 CM2350 F120B, F3.8 CM2350 F128C, QSF3.8 CM2350 F107, and ISF3.8 CM2350 F109, also incorporate the part 5268870. This screw is used in various applications within these engines, ensuring that components are tightly secured and properly aligned.

F3.8 CM2620 Series

The F3.8 CM2620 F137B engine uses the Hexagon Flange Head Cap Screw part 5268870 for securing specific components. This screw is crucial in maintaining the structural integrity of the engine.

F3.8 F102 Series

The F3.8 F102 engine employs the part 5268870 for securing certain parts within its assembly. This screw ensures that these components are held firmly in place, contributing to the engine’s overall performance and durability.

F4.5 CM2620 Series

The F4.5 CM2620 engines, including the F4.5 CM2620 F139B and F4.5 CM2620 F141C, use the Hexagon Flange Head Cap Screw part 5268870. This screw is vital for securing various components within these engines, ensuring proper alignment and stability.

ISF3.8 CM2220 Series

The ISF3.8 CM2220 engines, such as the ISF3.8 CM2220 AN and ISF3.8 CM2220 F103, incorporate the part 5268870. This screw is used in securing specific components within these engines, contributing to their structural integrity.

ISF4.5 CM2220 Series

The ISF4.5 CM2220 F123 engine uses the Hexagon Flange Head Cap Screw part 5268870 for securing certain parts within its assembly. This screw ensures that these components are held firmly in place, contributing to the engine’s overall performance and durability.

QSF3.8 CM2880 Series

The QSF3.8 CM2880 F112 engine employs the part 5268870 for securing specific components within its assembly. This screw ensures that these components are held firmly in place, contributing to the engine’s overall performance and durability.

Each of these engines relies on the Hexagon Flange Head Cap Screw part 5268870 to maintain the integrity and performance of their assemblies. This screw is a critical component in ensuring that the engine operates efficiently and reliably.

Hexagon Flange Head Cap Screw in Engine Systems

The part 5268870 Hexagon Flange Head Cap Screw is integral to the assembly and securement of various components within engine systems. Its robust design ensures reliable fastening, which is essential for maintaining the integrity and performance of the engine.

Application in Oil Cooler Systems

In oil cooler systems, the Hexagon Flange Head Cap Screw is used to fasten the oil cooler housing to the engine block or other structural components. This secure attachment is vital for maintaining the structural stability of the oil cooler, which is responsible for regulating the temperature of the engine oil. Proper fastening ensures that the oil cooler remains in place under the dynamic conditions of engine operation, thereby facilitating efficient heat exchange and prolonging the life of the engine oil.

Integration with Lubricating Oil Cooler Module

Within the lubricating oil cooler module, the Hexagon Flange Head Cap Screw plays a key role in securing the module to the engine. This module is designed to cool the lubricating oil, ensuring it remains at an optimal temperature for effective lubrication of engine components. The screw’s flange head provides additional surface area for a tighter and more secure fit, reducing the risk of vibration-induced loosening, which could compromise the cooling efficiency and lead to increased wear on engine parts.

Role in Engine Oil Cooler Assemblies

In engine oil cooler assemblies, the Hexagon Flange Head Cap Screw is employed to attach the cooler to the engine’s oil passages. This connection is essential for the proper flow of engine oil through the cooler, where it is cooled before being recirculated back into the engine. The screw’s design allows for easy installation and removal, facilitating maintenance and replacement of the cooler as needed.

Securing the Engine Oil Cooler

The engine oil cooler, a component dedicated to cooling the engine oil, relies on the Hexagon Flange Head Cap Screw for secure attachment to the engine. This ensures that the cooler remains firmly in place, allowing for consistent and efficient cooling of the engine oil. The screw’s hexagonal head provides a convenient interface for tools, enabling precise torque application during installation, which is important for maintaining the cooler’s sealing integrity and operational efficiency.

Contribution to Cooler Housing Stability

Finally, in the context of cooler housing, the Hexagon Flange Head Cap Screw is used to attach the housing to the engine or other supporting structures. This attachment is crucial for the housing’s stability, ensuring that it can withstand the pressures and temperatures associated with the cooling process. The screw’s design enhances the housing’s resistance to loosening, which is important for the long-term reliability of the cooling system.

Conclusion

The 5268870 Hexagon Flange Head Cap Screw by Cummins is a critical component in the maintenance and operation of commercial trucks. Its robust design, featuring a hexagonal head and flange, ensures reliable fastening and resistance to loosening, making it suitable for heavy-duty applications. Proper installation and maintenance of this screw are essential for ensuring the longevity and performance of truck components, particularly in engine systems where it plays a vital role in securing critical assemblies.

-

Ling, F. F. (2011). The Automotive Body. Springer Science.

↩ -

Denton, T., & Pells, H. (2022). Automotive Technician Training Theory. Routledge.

↩ -

Wright, G. (2015). Fundamentals of Medium-Heavy Duty Diesel Engines. Jones & Bartlett Learning.

↩ -

Reif, K. (2014). Diesel Engine Management Systems and Components. Springer.

↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.