5269996

Studded Flange Cap Screw

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 5269996 Studded Flange Cap Screw by Cummins is a specialized fastener designed for heavy-duty truck applications. Its purpose is to provide secure and reliable fastening in various truck components, ensuring the integrity and performance of the mechanical system. This screw is significant in maintaining the structural and functional stability of heavy-duty trucks, contributing to their overall efficiency and durability.

Basic Concepts

A Studded Flange Cap Screw is a type of fastener that includes a threaded stud and a flanged head. The stud is designed to be inserted through holes in the components being joined, while the flanged head provides a broad surface area for distribution of clamping force. This design allows for secure fastening and resistance to loosening under vibration and stress, which are common in heavy-duty truck environments. The 5269996 model by Cummins is engineered to meet the demanding requirements of truck applications, ensuring reliable performance in critical areas.

Purpose and Role

The 5269996 Studded Flange Cap Screw plays a role in the operation of a truck by securing various components together. It is commonly used in applications such as engine mounts, transmission housings, and chassis assemblies. By providing a strong and stable connection, this screw helps maintain the alignment and integrity of these components, which is vital for the truck’s performance and safety. Its applications extend to areas where high tensile strength and resistance to vibration are required.

Key Features

The 5269996 Studded Flange Cap Screw features a robust material composition, typically made from high-strength alloy steel. This ensures durability and resistance to wear and corrosion. The threading on the screw is precision-machined to provide a secure fit and easy installation. The flanged head design distributes clamping force evenly, reducing the risk of component damage. Additionally, the screw is designed to meet specific torque specifications, ensuring consistent performance across applications.

Benefits

The benefits of using the 5269996 Studded Flange Cap Screw include enhanced durability, reliability, and performance. Its high-strength material composition and precise threading contribute to a secure and long-lasting connection. The flanged head design provides additional stability, reducing the likelihood of loosening under dynamic conditions. These features collectively enhance the overall performance and longevity of the truck’s mechanical system.

Installation Process

Proper installation of the 5269996 Studded Flange Cap Screw involves several steps. First, ensure that the components to be joined are clean and free of debris. Insert the stud through the holes in the components, ensuring it is aligned correctly. Use a torque wrench to tighten the screw to the specified torque value, which ensures a secure connection without over-tightening. It is important to follow the manufacturer’s guidelines for torque settings to avoid damage to the screw or components.

Troubleshooting and Maintenance

Common issues associated with the 5269996 Studded Flange Cap Screw include loosening due to vibration and corrosion. Regular inspection and maintenance can help identify and address these issues. If loosening is detected, re-torque the screw to the specified value. In cases of corrosion, clean the affected areas and apply a suitable anti-corrosion treatment. Following these practices ensures the longevity and optimal performance of the screw.

Safety Considerations

When handling and installing the 5269996 Studded Flange Cap Screw, it is important to observe several safety guidelines. Wear appropriate personal protective equipment, such as gloves and safety glasses, to protect against injury. Ensure that the work area is clean and free of hazards. Follow the manufacturer’s torque specifications to avoid over-tightening, which can lead to component damage. Additionally, be aware of the potential for sharp edges on the screw and components, and handle them with care.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and reliability in the automotive and heavy-duty truck industry. The company’s commitment to excellence is reflected in its wide range of products, including the 5269996 Studded Flange Cap Screw, which is designed to meet the rigorous demands of heavy-duty applications.

Studded Flange Cap Screw (Part 5269996) Compatibility with Cummins Engines

The Studded Flange Cap Screw (Part 5269996) manufactured by Cummins is a critical component used in various engine configurations. This part is designed to ensure secure fastening of flanges, which is essential for maintaining the integrity of engine connections. Here is a detailed description of its compatibility with different Cummins engines:

B6.7 Series

- B6.7 CM2670

- ISB6.7 CM2250

- ISB6.7 CM2350 B101

- ISB6.7 G CM2180 B118

- QSB6.7 CM2250

- QSB6.7 CM2350 B105

- QSB6.7 CM850 (CM2850)

- QSB6.7 M CM2250

The Studded Flange Cap Screw is integral to the B6.7 series engines, ensuring robust connections in high-stress environments. These engines are known for their durability and performance, and the screw’s design supports these characteristics by providing reliable fastening.

ISB Series

- ISB (Chrysler)

- ISB CM2150

- ISB CM850

- ISB/ISD4.5 CM2150 B119

- ISB/ISD6.7 CM2150 SN

- ISB5.9G CM2180

- ISB6.7 CM2350 B101

- ISB6.7 G CM2180 B118

- ISBE CM2150

- ISBE4 CM850

The ISB series engines benefit from the Studded Flange Cap Screw’s ability to withstand significant mechanical stress. This screw is used in various configurations within the ISB lineup, ensuring that flanges are securely fastened, which is crucial for maintaining engine performance and longevity.

QSB Series

- QSB4.5 CM2250 EC

- QSB4.5 CM850 (CM2850)

- QSB6.7 CM2250

- QSB6.7 CM2350 B105

- QSB6.7 CM850 (CM2850)

- QSB6.7 M CM2250

- QSB7 CM2880 B117

The QSB series engines, particularly those with the 4.5 and 6.7 liter displacements, rely on the Studded Flange Cap Screw for critical flange connections. This screw’s design ensures that flanges are tightly secured, which is vital for the efficient operation of these engines.

Other Series

- F2.8 CM2620 F135B

- ISF2.8 CM2220 F129

- QSF2.8 CM2880 F104

- QSL9 CM2350 L102

- X12 CM2350 X119B

The Studded Flange Cap Screw is also used in the F2.8 and QSF2.8 series engines, as well as the QSL9 and X12 engines. These engines, while differing in specifications, all benefit from the screw’s ability to provide a secure and reliable flange connection. This ensures that the engines operate efficiently and safely under various conditions.

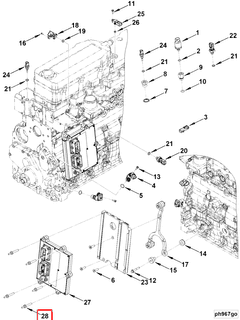

Role of Part 5269996 Studded Flange Cap Screw in Engine Systems

The part 5269996 Studded Flange Cap Screw is integral in securing and maintaining the integrity of various engine components. Its application spans across multiple systems, ensuring that each part functions cohesively within the engine arrangement.

In the turbocharger system, this screw is utilized to fasten the turbocharger to the engine, ensuring a secure connection that can withstand the high pressures and temperatures generated during operation.

Within the cooler system, it plays a role in attaching the cooler to its mounting brackets, facilitating efficient heat exchange and maintaining optimal engine temperatures.

For the engine oil system, the screw is employed in securing oil passages and fittings, guaranteeing a leak-free environment and consistent oil flow to lubricate moving parts.

In the drive system, it is used to attach components such as the fan, ensuring that the drive mechanism operates smoothly and efficiently.

The fuel filter mounting relies on this screw to secure the fuel filter in place, which is essential for clean fuel delivery to the engine.

In the harness and engine control wiring, the screw is instrumental in securing wiring looms and connectors, protecting the electrical components from vibrations and ensuring reliable signal transmission.

For the long block and long block kit, it is used in various mounting points to ensure the structural integrity of the engine assembly.

In the module and engine control systems, the screw is crucial for attaching control modules and sensors, ensuring they are correctly positioned and securely fastened.

The fuel filter and pump systems also benefit from this screw, as it is used to secure the fuel filter and pump components, ensuring a stable fuel supply.

In the auxiliary systems, such as the ignition system, the screw is employed to attach ignition components, ensuring precise and reliable ignition timing.

Overall, the part 5269996 Studded Flange Cap Screw is a versatile component that enhances the reliability and performance of various engine systems by providing secure and stable connections.

Conclusion

The 5269996 Studded Flange Cap Screw by Cummins is a critical component in heavy-duty truck applications, providing secure and reliable fastening for various engine components. Its robust design, high-strength material, and precise threading ensure durability, reliability, and performance. Proper installation and maintenance are essential to maximize its benefits and ensure the longevity of the truck’s mechanical system. Cummins’ commitment to quality and innovation is evident in the design and functionality of this part, making it a valuable asset in the automotive and heavy-duty truck industry.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.