5270031

Hexagon Flange Head Cap Screw

Cummins®

AVAILABLE

8 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Hexagon Flange Head Cap Screw, identified by part number 5270031, is a component manufactured by Cummins, a prominent name in the commercial truck industry. This screw plays a significant role in the assembly and operation of commercial trucks, ensuring the secure fastening of various components. Cummins, known for its robust and reliable parts, provides this screw as part of its extensive range of truck components.

Basic Concepts

A Hexagon Flange Head Cap Screw is a type of fastener characterized by its hexagonal head and a flange beneath the head. The hexagonal head allows for efficient torque application using standard tools, while the flange provides additional surface area to distribute the load and prevent the screw from sinking into the material. In the context of a truck’s assembly, this screw is used to secure components that require a strong, vibration-resistant connection.

Purpose and Role in Truck Operation

This Cummins part is designed to secure critical components within a truck’s assembly. It is commonly used in applications where components are subjected to significant stress and vibration, such as in the engine compartment, transmission housing, and chassis. By providing a secure and stable connection, this screw helps maintain the integrity and performance of the truck’s various systems.

Key Features

The Hexagon Flange Head Cap Screw features a hexagonal head that allows for easy and precise torque application. The flange beneath the head provides additional surface area, which helps distribute the load and prevents the screw from sinking into the material. Additionally, the screw is made from high-quality materials that offer excellent durability and resistance to corrosion, ensuring long-lasting performance in demanding environments.

Benefits

Using this part offers several advantages. Its durable construction ensures longevity, even in harsh operating conditions. The screw’s resistance to vibration helps maintain a secure connection over time, reducing the need for frequent re-tightening. Additionally, the hexagonal head design allows for easy installation and removal using standard tools, making it a convenient choice for both maintenance and repair tasks.

Installation Process

Proper installation of the Hexagon Flange Head Cap Screw is crucial for ensuring optimal performance and longevity. Begin by cleaning the installation area to remove any debris or contaminants. Use a torque wrench to apply the recommended torque specification, ensuring the screw is tightened to the manufacturer’s guidelines. It is important to avoid over-tightening, as this can lead to damage or stripping of the screw or the surrounding material.

Troubleshooting Common Issues

Common issues associated with Hexagon Flange Head Cap Screws include loosening due to vibration, corrosion, and damage from improper installation. To address these issues, regularly inspect the screws for signs of loosening or corrosion. If a screw appears loose, re-tighten it to the recommended torque specification. In cases of corrosion, consider replacing the screw to prevent further degradation. Ensuring proper installation techniques can help mitigate damage and extend the lifespan of the screw.

Maintenance Tips

Regular maintenance of the Hexagon Flange Head Cap Screw is important for continued reliable performance. Inspect the screws periodically for signs of wear, corrosion, or loosening. Clean the installation area as needed to remove any buildup that could affect the screw’s performance. Follow the manufacturer’s guidelines for torque specifications during installation and re-tightening to ensure the screw remains secure. Replace any screws that show significant wear or damage to maintain the integrity of the truck’s assembly.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation for quality and reliability in the commercial truck industry. The company offers a wide range of products and services designed to meet the needs of customers in various sectors, including transportation, construction, and agriculture. Cummins’ commitment to innovation and customer satisfaction has made it a trusted name in the industry.

Cummins Engine Part 5270031: Hexagon Flange Head Cap Screw

The Cummins part number 5270031, a Hexagon Flange Head Cap Screw, is a critical component in various Cummins engine models. This screw is designed to provide secure fastening in applications where high strength and durability are essential. Below is a detailed description of how this part integrates with specific Cummins engines.

Integration with Cummins Engines

15N Series Engines

- 15N CM2380 M104B

- 15N CM2380 B152B

The Hexagon Flange Head Cap Screw is used in the 15N series engines to secure various components, ensuring that parts remain tightly fastened under operational stresses.

B5.6 and B5.9 Series Engines

- B5.6 CM2670 B152B

- B5.9 CM2670 B166C

In the B5.6 and B5.9 series engines, the part 5270031 is employed in several critical areas, including securing engine covers and housings, ensuring the integrity of the engine’s structure.

D4.0 and F Series Engines

- D4.0 CM2620 D103B

- F3.8 CM2350 F120B

- F3.8 CM2620 F137B

- F4.5 CM2620 F139B

- F4.5 CM2620 F141C

For the D4.0 and F series engines, the Hexagon Flange Head Cap Screw is utilized in fastening various engine components, including but not limited to, cylinder heads, intake manifolds, and exhaust systems. This ensures that these parts are securely held in place, contributing to the engine’s overall performance and longevity.

ISB Series Engines

- ISB3.9 CM2220 B107

- ISB5.9 CM2880 B127

In the ISB series engines, the part 5270031 is used in securing components such as engine blocks, cylinder heads, and other critical parts, ensuring that the engine maintains its structural integrity under high operational loads.

ISF Series Engines

- ISF2.8 CM2220 F129

- ISF3.8 CM2220 AN

- ISF3.8 CM2350 F109

The ISF series engines also utilize the Hexagon Flange Head Cap Screw in various applications, including securing engine covers and other structural components, ensuring that the engine operates smoothly and efficiently.

ISG Series Engines

- ISG12 CM2880 G107

In the ISG series engines, this screw is used to fasten components that require high strength and durability, contributing to the engine’s overall performance.

L9 Series Engines

- L9 CM2670 L128B

The L9 series engines use the part 5270031 in securing various engine components, ensuring that the engine operates reliably under different conditions.

QSB Series Engines

- QSB5.9 CM2880 B139

- QSB7 CM2880 B117

In the QSB series engines, the Hexagon Flange Head Cap Screw is used in securing critical components, ensuring the engine’s structural integrity and performance.

QSF Series Engines

- QSF3.8 CM2350 F107

- QSF3.8 CM2880 F112

The QSF series engines utilize the part 5270031 in securing various engine components, ensuring that the engine operates efficiently and reliably.

QSK Series Engines

- QSK50 CM2350 K108

In the QSK series engines, the Hexagon Flange Head Cap Screw is used in securing critical components, ensuring the engine’s structural integrity and performance.

X13 Series Engines

- X13 CM2670 X122B

The X13 series engines use the part 5270031 in securing various engine components, ensuring that the engine operates reliably under different conditions.

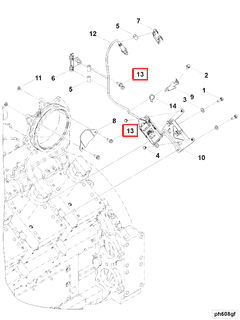

Role of Part 5270031 Hexagon Flange Head Cap Screw in Engine Systems

This part is integral in securing various components within engine systems, ensuring stability and proper function. It is commonly used in the fastening of accessories, which may include electrical components and heat shields. Its application extends to the arrangement and secure attachment of the heat shield, which is vital for managing engine temperatures and protecting nearby components from excessive heat.

In the context of the exhaust system, this screw plays a significant role in the connection between the exhaust outlet and the exhaust recirculation air module. This ensures a sealed and efficient flow of gases, contributing to the reduction of nitrogen oxide emissions. The screw’s location in these systems is strategically chosen to maintain the integrity of the plumbing and the overall exhaust recirculation process.

Furthermore, the part 5270031 is utilized in the engine control module’s shielding, providing a robust connection that safeguards sensitive electronic components from environmental factors and mechanical vibrations. Its application in the turbocharger area is also noteworthy, where it helps in securing components that are subject to high stress and temperature variations.

Overall, the Hexagon Flange Head Cap Screw is a fundamental fastening element in engine systems, contributing to the secure and efficient operation of various components.

Conclusion

The 5270031 Hexagon Flange Head Cap Screw is a vital component in the assembly and operation of Cummins engines, ensuring the secure fastening of various critical components. Its durable construction, resistance to vibration, and ease of installation make it an essential part for maintaining the integrity and performance of engine systems. Proper installation, regular maintenance, and timely replacement of worn or damaged screws are crucial for the continued reliable operation of commercial trucks.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.