5270231

Banjo Connector Screw

Cummins®

AVAILABLE

1 is currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 5270231 Banjo Connector Screw, manufactured by Cummins, is a critical component utilized in commercial truck systems. Cummins, a well-established name in the industry, produces a range of parts designed to enhance the performance and reliability of heavy-duty trucks. This part is significant due to its role in ensuring the efficient operation of fluid systems within these vehicles.

Basic Concepts of Banjo Connector Screws

A Banjo Connector Screw is a type of fitting used in fluid systems to connect hoses or pipes to various components. It typically consists of a bolt with an integrated fitting that allows for the secure attachment of a hose or pipe. In a truck’s hydraulic or fuel system, this component facilitates the transfer of fluids under pressure, ensuring that systems operate smoothly and efficiently 1.

Purpose of the 5270231 Banjo Connector Screw

The 5270231 Banjo Connector Screw is designed to play a specific role in the operation of a truck, particularly within its hydraulic or fuel lines. This component ensures a secure and leak-free connection between the hose and the system, contributing to the overall reliability and performance of the truck’s fluid systems.

Key Features

The 5270231 Banjo Connector Screw is characterized by several design and construction features. It is typically made from high-quality materials to ensure durability and resistance to corrosion. The screw features a specific thread type that matches the requirements of the system it is intended for, and it incorporates sealing mechanisms to prevent leaks. These features contribute to the connector’s effectiveness in demanding environments 2.

Benefits

Using the 5270231 Banjo Connector Screw offers several advantages. Its durable construction ensures long-term reliability, while its design helps to prevent leaks, maintaining the integrity of the fluid system. Additionally, the connector is designed for ease of installation, allowing for quick and efficient replacement or maintenance.

Installation Process

Proper installation of the 5270231 Banjo Connector Screw involves several steps. First, ensure that the mating surface is clean and free of debris. Align the connector with the fitting, then carefully thread it into place. It is important to follow torque specifications to ensure a secure fit without over-tightening, which could damage the connector or the fitting 3.

Maintenance and Troubleshooting

Regular maintenance of the 5270231 Banjo Connector Screw involves inspecting it for signs of wear or damage, such as corrosion or leaks. If issues are detected, it may be necessary to clean or replace the connector to ensure the continued reliability of the fluid system. Troubleshooting common problems, such as leaks, often involves checking the tightness of the connection and the condition of the sealing surfaces.

Compatibility and Applications

The 5270231 Banjo Connector Screw is designed for use in various truck models and systems, demonstrating its versatility. It is compatible with a range of Cummins engines and is often found in applications where secure and leak-free fluid connections are required.

Safety Considerations

When working with the 5270231 Banjo Connector Screw, it is important to observe safety protocols. This includes wearing appropriate personal protective equipment, ensuring that the system is depressurized before beginning work, and following all manufacturer guidelines for installation and maintenance. These precautions help to ensure a safe working environment 4.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and related technologies. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. The company’s extensive product range and commitment to customer satisfaction have made it a preferred choice for professionals in the field.

Cummins Engine Compatibility with Part 5270231

The Banjo Connector Screw, part number 5270231, manufactured by Cummins, is a critical component in the engine systems of various Cummins engines. This part is designed to ensure a secure and leak-free connection for fuel, oil, or coolant lines, which is essential for the proper functioning of the engine.

15N CM2380 M104B, F4.5 CM2620 F141C

The Banjo Connector Screw is compatible with the 15N CM2380 M104B and F4.5 CM2620 F141C engines. These engines are known for their robust design and reliability, often used in heavy-duty applications. The part ensures that the connections for fuel and other fluids remain tight and secure, preventing any potential leaks that could compromise engine performance.

ISB6.7 G CM2180 B118

The ISB6.7 G CM2180 B118 engine also benefits from the use of the Banjo Connector Screw. This engine is part of the Cummins ISB series, which is widely recognized for its power and efficiency. The screw is essential in maintaining the integrity of the connections in this engine, ensuring that all fluid lines are properly sealed and secure.

QSB3.3 CM2250 EC, QSB4.5 CM2250 EC

The QSB3.3 CM2250 EC and QSB4.5 CM2250 EC engines are another set of engines that utilize the Banjo Connector Screw. These engines are part of the Cummins QSB series, known for their versatility and performance in various applications. The screw plays a crucial role in maintaining the fluid connections in these engines, ensuring that they operate smoothly and efficiently.

Role of Part 5270231 Banjo Connector Screw in Engine Systems

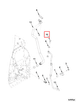

The 5270231 Banjo Connector Screw is an essential component in the efficient operation of various engine systems, particularly in the context of plumbing and turbocharger setups.

In plumbing systems, this screw plays a significant role in securing connections between pipes and fittings. It ensures a tight seal, which is vital for maintaining the integrity of the fluid transfer process. Whether it’s fuel, oil, or coolant, the secure fitting provided by the Banjo Connector Screw prevents leaks and ensures consistent flow, which is fundamental for the engine’s performance and longevity.

When it comes to turbocharger systems, the Banjo Connector Screw is equally important. Turbochargers require precise and secure connections for the oil feed and return lines to function correctly. The screw ensures that these connections are leak-free, allowing the turbocharger to receive the necessary lubrication. This lubrication is essential for the turbocharger’s bearings and other moving parts, directly influencing its efficiency and durability.

In turbocharger plumbing, the Banjo Connector Screw is often used in the oil supply and drain lines. Its role here is to maintain a secure connection that can withstand the high pressures and temperatures associated with turbocharger operation. This ensures that the oil supply to the turbocharger is consistent, which is necessary for optimal performance and to prevent damage from inadequate lubrication.

Conclusion

The 5270231 Banjo Connector Screw is a key component in ensuring the reliability and efficiency of engine systems by providing secure and leak-free connections in critical areas. Its compatibility with various Cummins engines underscores its importance in maintaining the performance and longevity of heavy-duty trucks.

-

Kershaw, John F. SAE International’s Dictionary for Automotive Engineers. SAE International, 2023.

↩ -

Peters, George, and Barbara J Peters. Automobile Vehicle Safety. CRC Press, 2002.

↩ -

Eret, Angelina. Dynamic and Fatigue Assessment of Heavy-Duty Engine Valves. Springer Nature, 2024.

↩ -

Kluczyk, Barry. How to Rebuild Any Automotive Engine. CarTech, 2008.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.