This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 5271297 Studded Flange Cap Screw is a specialized fastener designed for heavy-duty truck applications. Manufactured by Cummins, a well-established company known for its high-quality automotive components, this screw is integral to ensuring secure and reliable fastening in various truck components, contributing to the overall performance and durability of heavy-duty vehicles.

Basic Concepts of Studded Flange Cap Screws

A studded flange cap screw is a type of fastener that combines the features of a stud and a cap screw. It consists of a threaded shaft with a flange at one end, which provides additional surface area for load distribution and resistance to loosening. Unlike standard cap screws, which are fully threaded and require a nut for fastening, studded flange cap screws are partially threaded and can be directly screwed into a tapped hole. This design offers advantages in applications where space is limited or where a nut cannot be used 1.

Purpose and Role in Truck Operation

The 5271297 Studded Flange Cap Screw plays a significant role in the operation of heavy-duty trucks by providing secure fastening in critical components. It is commonly used in applications where high tensile strength and resistance to vibration are required, such as in engine mounts, transmission housings, and chassis components. The flange design helps distribute loads more evenly and prevents the screw from loosening over time, ensuring the integrity of the fastened components 2.

Key Features

The 5271297 Studded Flange Cap Screw boasts several key features that enhance its performance and reliability. It is made from high-strength alloy steel, which provides excellent tensile strength and durability. The screw has a coarse thread pitch, allowing for quick and easy installation. The flange at the end of the screw is designed to provide additional surface area for load distribution, reducing the risk of stripping or damage to the fastened material. Additionally, the screw is coated with a corrosion-resistant finish to protect against rust and environmental factors 3.

Benefits

Using the 5271297 Studded Flange Cap Screw offers several benefits in heavy-duty truck applications. Its high-strength material composition ensures durability and resistance to wear and tear. The flange design enhances load distribution, reducing the risk of damage to the fastened components. The screw’s resistance to vibration and loosening ensures secure fastening over time, even in demanding operating conditions. Additionally, the corrosion-resistant coating protects the screw from rust and environmental factors, prolonging its lifespan and maintaining reliable performance.

Installation Guidelines

Proper installation of the 5271297 Studded Flange Cap Screw is crucial to ensure secure fastening and optimal performance. Follow these step-by-step guidelines for installation:

- Prepare the Hole: Ensure the tapped hole is clean and free of debris. Use a tap to create or clean the threads if necessary.

- Align the Screw: Position the screw so that the flange is aligned with the surface of the component being fastened.

- Insert the Screw: Carefully screw the 5271297 Studded Flange Cap Screw into the tapped hole by hand to avoid cross-threading.

- Tighten the Screw: Use a torque wrench to tighten the screw to the specified torque value. Refer to the manufacturer’s guidelines for the recommended torque specification.

- Check for Security: Ensure the screw is securely fastened and the flange is flush with the surface of the component.

Troubleshooting and Maintenance

Common issues with studded flange cap screws include loosening, corrosion, and damage to the threads. To troubleshoot these issues:

- Loosening: If the screw loosens over time, check for proper torque and ensure the flange is in contact with the surface. Re-tighten if necessary.

- Corrosion: Inspect the screw for signs of rust or corrosion. Clean the screw and apply a corrosion-resistant coating if needed.

- Thread Damage: If the threads are damaged, use a tap to repair or replace the screw if necessary.

Regular maintenance, such as periodic inspection and re-tightening, can help prolong the lifespan of the screw and ensure continued reliable performance.

Cummins: Manufacturer Overview

Cummins is a renowned manufacturer with a long-standing reputation in the automotive industry. Founded in 1919, Cummins has been at the forefront of innovation and quality in engine and component manufacturing. The company is committed to delivering high-performance, reliable products that meet the demanding requirements of heavy-duty applications. Cummins’ dedication to quality, innovation, and customer satisfaction has established them as a trusted name in the industry, making them a preferred choice for automotive components, including the 5271297 Studded Flange Cap Screw.

Integration of Studded Flange Cap Screw in Cummins Engines

The Studded Flange Cap Screw, part number 5271297, manufactured by Cummins, is a critical component in the assembly and maintenance of several Cummins engine models. This part is integral to ensuring the secure fastening of flanges, which are essential for sealing and connecting various parts within the engine system.

F3.8 CM2620 F137B and F4.5 CM2620 F139B

In the F3.8 CM2620 F137B and F4.5 CM2620 F139B engines, the Studded Flange Cap Screw is utilized in multiple applications where flanges need to be tightly secured. These engines, part of the CM2620 series, are known for their robust design and reliability in demanding applications. The screw’s studded design provides a strong grip, preventing loosening due to vibrations and thermal expansion, which is crucial for maintaining the integrity of the engine’s sealing and structural components.

ISF3.8 CM2220 AN

The ISF3.8 CM2220 AN engine also incorporates the Studded Flange Cap Screw in its assembly. This engine model, part of the CM2220 series, is designed for high-performance and durability. The use of this screw in the ISF3.8 CM2220 AN engine ensures that all flange connections are securely fastened, which is vital for the engine’s operational efficiency and longevity. The studded feature of the screw provides additional resistance to loosening, which is particularly beneficial in the high-stress environments these engines often operate in.

The Studded Flange Cap Screw’s role in these engines is to provide a reliable and secure fastening solution, ensuring that all flange connections remain tight and secure throughout the engine’s operational life. This is crucial for maintaining the engine’s performance, preventing leaks, and ensuring the safety and reliability of the engine system.

Role of Part 5271297 Studded Flange Cap Screw in Engine Systems

In the context of engine systems, the part 5271297 Studded Flange Cap Screw is instrumental in ensuring the secure assembly and operation of various components. Specifically, it plays a significant role in the arrangement and functionality of turbochargers.

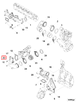

Turbocharger Arrangement

Within the turbocharger arrangement, the Studded Flange Cap Screw is utilized to fasten critical components together, providing the necessary tension and stability. This ensures that the turbocharger’s components, such as the turbine and compressor, remain securely attached during operation. The screw’s design allows it to withstand high temperatures and pressures, which are common in turbocharger environments.

Turbocharger

In the turbocharger itself, the Studded Flange Cap Screw is often used to secure the turbocharger housing to the engine block or exhaust manifold. This connection is vital for maintaining the integrity of the turbocharger’s seals and ensuring that exhaust gases flow efficiently through the turbine. The screw’s studded flange provides additional surface area for a more robust connection, reducing the risk of leaks and enhancing overall performance.

By integrating the Studded Flange Cap Screw into these engine components, engineers and mechanics can achieve a more reliable and efficient turbocharger system, ultimately contributing to the engine’s performance and durability.

Conclusion

The 5271297 Studded Flange Cap Screw is a critical component in heavy-duty truck applications, providing secure and reliable fastening in various engine and chassis components. Its high-strength material, flange design, and corrosion-resistant coating ensure durability and performance in demanding environments. Proper installation and maintenance are essential to maximize the benefits of this Cummins part, contributing to the overall reliability and efficiency of heavy-duty vehicles.

-

Richards, P., & Barker, J. (2023). Automotive Fuels Reference Book. SAE International.

↩ -

Boger, T., & Cutler, W. (2018). Reducing Particulate Emissions in Gasoline Engines. SAE International.

↩ -

Brach, R. M. (2023). SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.