This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Hexagon Flange Head Cap Screw, identified by part number 5274320, is a component manufactured by Cummins, a leader in the automotive and heavy-duty truck industry. This screw is significant in commercial truck maintenance due to its robust design and reliable performance. Cummins is renowned for its commitment to quality and innovation, making this part a trusted choice for professionals in the field.

Basic Concepts

A Hexagon Flange Head Cap Screw is a type of fastener characterized by its hexagonal head and flanged base. The hexagonal head allows for efficient tightening and loosening using a wrench, while the flange provides additional surface area to distribute load and prevent the screw from sinking into the material. In the context of truck components, this screw is used to secure various parts, ensuring they remain firmly in place under operational stress.

Purpose and Role in Truck Operation

The 5274320 Hexagon Flange Head Cap Screw plays a role in the operation and maintenance of commercial trucks by securing critical components. It is applied in various truck systems, including the engine, transmission, and chassis. By providing a secure fastening solution, it helps maintain the integrity and performance of these systems. Its design ensures that components remain aligned and stable, contributing to the overall reliability of the truck.

Key Features

The 5274320 Hexagon Flange Head Cap Screw features a hexagonal flange head design, which offers several advantages. The hexagonal shape allows for precise torque application, reducing the risk of over-tightening or stripping. The flange head provides additional bearing surface, enhancing the screw’s ability to withstand load and vibration. Additionally, the screw is typically made from high-strength materials, such as alloy steel, which contributes to its durability and resistance to corrosion 1.

Benefits

The 5274320 Hexagon Flange Head Cap Screw offers several benefits that enhance its performance in commercial truck applications. Its design provides improved fastening security, ensuring that components remain securely attached even under dynamic conditions. The screw’s resistance to vibration helps prevent loosening over time, reducing the need for frequent re-tightening. Additionally, the ease of installation and removal makes it a practical choice for maintenance tasks 2.

Installation and Usage

Proper installation of the 5274320 Hexagon Flange Head Cap Screw is crucial for optimal performance. It should be installed using the appropriate torque specifications to ensure a secure fit without over-tightening. Best practices include cleaning the installation surface to remove any debris or corrosion, which can affect the screw’s holding power. Using a torque wrench is recommended to achieve the correct tightening force, ensuring the screw is neither under-tightened nor over-tightened 3.

Troubleshooting and Maintenance

Common issues with the 5274320 Hexagon Flange Head Cap Screw may include loosening due to vibration or corrosion. Regular inspection and maintenance can help identify and address these issues promptly. If loosening is detected, re-tightening the screw to the specified torque is typically sufficient. In cases of corrosion, cleaning the affected area and applying a corrosion-resistant coating can help prolong the screw’s service life 4.

Safety Considerations

When working with the 5274320 Hexagon Flange Head Cap Screw, it is important to follow safety protocols to ensure a safe working environment. Proper handling involves using the correct tools to avoid damage to the screw or surrounding components. Storage should be in a dry, corrosion-resistant environment to maintain the screw’s integrity. Disposal should comply with local regulations for metal waste, ensuring environmental safety 5.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. Founded in 1919, Cummins has a long-standing reputation for quality and innovation. The company’s product range includes engines for on-highway and off-highway applications, as well as filtration and power generation systems. Cummins is committed to advancing technology and sustainability in the automotive industry, providing solutions that meet the evolving needs of its customers.

Cummins Engine Compatibility with Hexagon Flange Head Cap Screw

The Cummins part 5274320, a Hexagon Flange Head Cap Screw, is designed to fit seamlessly within the engine architecture of several Cummins engines. This particular screw is integral to the assembly and maintenance of these engines, ensuring secure fastening and reliability.

ISB4.5 CM2350 B104

The ISB4.5 CM2350 B104 engine benefits from the precision and strength of the 5274320 screw. This engine, known for its robust performance, utilizes the screw in various critical applications where secure fastening is paramount. The screw’s design ensures that it can withstand the operational stresses and environmental conditions typical of this engine’s use.

ISF2.8 CM2220 F129

Similarly, the ISF2.8 CM2220 F129 engine incorporates the 5274320 screw in its assembly. This engine, recognized for its efficiency and reliability, relies on the screw for maintaining the integrity of its components. The screw’s hexagonal flange head provides a secure grip, essential for the engine’s operational demands.

Common Applications

Both engines utilize the 5274320 screw in similar contexts, such as securing engine covers, mounting brackets, and other critical components. The screw’s design ensures that it can be easily installed and removed, facilitating maintenance and repair processes. Its use in these engines underscores its importance in maintaining the structural and operational integrity of the engine.

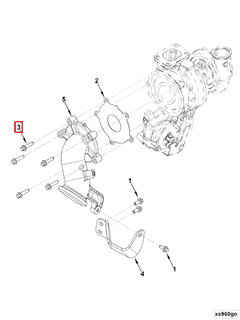

Part 5274320 Hexagon Flange Head Cap Screw Component Usage

The part 5274320 Hexagon Flange Head Cap Screw is integral in various applications within engine systems, particularly in ensuring secure connections and maintaining the integrity of components under high stress and temperature conditions.

Connection

In engine systems, the Hexagon Flange Head Cap Screw is often used to create robust connections between different components. Its design allows for a snug fit, which is essential for components that experience significant vibration and stress. For instance, it is commonly employed in securing brackets, mounts, and other structural elements that support the engine or its subsystems. The flange head provides additional surface area for distribution of clamping force, reducing the risk of stripping or damage to the connected parts.

Exhaust Outlet

At the exhaust outlet, the Hexagon Flange Head Cap Screw plays a significant role in securing the exhaust manifold to the engine block or cylinder head. This connection is vital for maintaining the seal and ensuring that exhaust gases are directed efficiently away from the engine. The screw’s flange head helps in distributing the clamping force evenly, which is important for preventing leaks and ensuring that the exhaust system operates within specified parameters. Additionally, the screw’s resistance to high temperatures and corrosion makes it suitable for this application, where it is exposed to the harsh environment of exhaust gases.

Conclusion

The 5274320 Hexagon Flange Head Cap Screw is a critical component in the maintenance and operation of commercial trucks and Cummins engines. Its robust design, ease of installation, and resistance to vibration and corrosion make it an essential part for securing various engine components. Proper installation and maintenance practices are vital to ensure the screw’s optimal performance and longevity.

-

Bonneau, D., Fatu, A., & Souchet, D. (2014). Internal Combustion Engine Bearings Lubrication in Hydrodynamic Bearings. Wiley-ISTE.

↩ -

Schuetz, T. (2016). Aerodynamics of Road Vehicles: Fifth Edition. SAE International.

↩ -

Dempsey, P. (2018). Troubleshooting and Repairing Diesel Engines, 5th Edition. McGraw-Hill.

↩ -

Taghavifar, H., & Mardani, A. (2017). Offroad Vehicle Dynamics Analysis Modelling and Optimization. Springer.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 5579941.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.