5287028

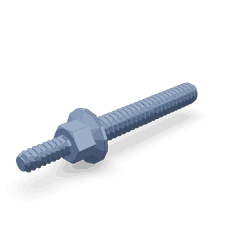

Studded Flange Cap Screw

Cummins®

IN STOCK

1 is currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Studded Flange Cap Screw, identified by part number 5287028, is a component manufactured by Cummins. This screw is significant in heavy-duty truck applications due to its role in securing various components within the truck’s mechanical system. Cummins, a reputable name in the automotive industry, is known for its commitment to quality and innovation in manufacturing truck components 1.

Basic Concepts

A Studded Flange Cap Screw is a type of fastener that includes a threaded stud and a flanged head. The stud extends through holes in the components being joined, and a nut is typically used on the opposite side to secure the assembly. The flanged head provides additional surface area for torque application, enhancing the screw’s ability to hold components firmly in place. In a truck’s mechanical system, these screws are used to secure parts that require a high level of stability and resistance to vibration 2.

Purpose and Role

This Cummins part serves to secure and maintain the integrity of various truck components. It is designed to withstand the rigors of heavy-duty applications, ensuring that parts remain firmly attached under significant stress and vibration. This screw plays a role in the structural integrity of the truck by providing a reliable fastening solution for critical components.

Key Features

The 5287028 is constructed from high-strength materials, ensuring durability and resistance to wear. Its design includes a studded section that threads through the components and a flanged head that allows for secure tightening. The screw’s material composition and design elements contribute to its performance and longevity in demanding environments.

Benefits

The use of the Studded Flange Cap Screw offers several benefits. It provides improved reliability by ensuring that components remain securely fastened, even under harsh conditions. Enhanced performance is achieved through its robust design, which resists loosening due to vibration. Additionally, the durability of this screw can lead to potential cost savings for fleet operators by reducing the need for frequent replacements 3.

Installation and Usage

Proper installation of this part involves aligning the stud with the holes in the components and using a nut to secure it from the opposite side. It is important to follow recommended torque specifications to ensure the screw is tightened to the correct level, providing optimal performance without over-tightening, which could damage the components or the screw itself. Best practices include using the appropriate tools and ensuring that all surfaces are clean and free of debris before installation.

Troubleshooting and Maintenance

Common issues with the Studded Flange Cap Screw may include loosening over time due to vibration or corrosion. Regular inspections can help identify these issues early. Maintenance tips include checking the tightness of the screw periodically and applying a thread locker if necessary to prevent loosening. Additionally, protecting the screw from corrosion by ensuring it is properly coated or treated can prolong its lifespan.

Safety Considerations

When working with the Studded Flange Cap Screw, it is important to follow proper handling procedures. This includes using the correct tools for installation and removal to avoid damage to the screw or the components it secures. Precautions should be taken to prevent accidents or injuries, such as wearing appropriate personal protective equipment and ensuring that the work area is safe and free of hazards.

Cummins Overview

Cummins is a well-established company in the automotive industry, known for its history of innovation and quality in manufacturing truck components. The company’s reputation is built on a commitment to delivering reliable and high-performance parts that meet the demands of heavy-duty applications. Cummins continues to invest in research and development to advance its product offerings and maintain its position as a leader in the industry.

Studded Flange Cap Screw (Part 5287028) in ISB Engines

The Studded Flange Cap Screw, part number 5287028, manufactured by Cummins, plays a role in the assembly and operation of the ISB engines. This part is integral to the ISB (Chrysler) and ISB CM850 engines, ensuring secure fastening and stability of various components.

ISB (Chrysler) Engine

In the ISB (Chrysler) engine, the Studded Flange Cap Screw is used to fasten components that require a robust and reliable connection. The studded design of the screw provides enhanced grip and resistance to loosening, which is essential for maintaining the integrity of the engine’s structure under high operational stresses.

ISB CM850 Engine

Similarly, in the ISB CM850 engine, the Studded Flange Cap Screw is employed in critical applications where secure fastening is paramount. The CM850 variant, known for its durability and performance, benefits from the reliability of this part in maintaining the alignment and stability of various engine components.

The use of part 5287028 in these engines underscores its importance in ensuring the longevity and efficiency of the ISB engine family. The studded flange cap screw’s design allows it to withstand the demanding conditions of engine operation, providing a dependable solution for securing flanges and other critical parts.

Role of Part 5287028 Studded Flange Cap Screw in Engine Systems

The Part 5287028 Studded Flange Cap Screw is a component in various engine systems, ensuring secure and reliable connections across multiple subsystems.

In the fuel system, this screw is often used to fasten the fuel filter to its housing, ensuring a leak-free connection that maintains fuel integrity and pressure. It also plays a role in securing the fuel gauge sender unit to the fuel tank, providing accurate readings of fuel levels.

Within the oil system, the screw is employed to attach the oil level gauge to the engine block or oil pan. This ensures precise measurement of oil levels, which is vital for maintaining proper lubrication and engine health. Additionally, it secures the oil level sensor, contributing to the accuracy of oil level readings displayed on the dashboard.

In the air intake system, the Part 5287028 screw is utilized to fasten components of the manifold to the engine, ensuring a tight seal that prevents air leaks. This is important for maintaining optimal air-fuel ratios and engine performance.

For the plumbing of engine coolant and other fluids, this screw ensures that connections remain secure under varying temperatures and pressures, preventing leaks that could lead to system failure.

Lastly, in the fuel injection system, the screw is used to secure injectors to the engine block or manifold. This ensures that injectors remain firmly in place, allowing for precise fuel delivery and combustion efficiency.

Overall, the Part 5287028 Studded Flange Cap Screw contributes to the integrity and functionality of various engine systems by providing secure, leak-proof connections.

Conclusion

The Studded Flange Cap Screw, part number 5287028, is a critical component in heavy-duty truck applications, particularly within Cummins’ ISB engines. Its robust design, high-strength materials, and flanged head contribute to its reliability and performance in securing various engine components. Proper installation, maintenance, and safety considerations are essential to maximize the benefits of this part, ensuring the longevity and efficiency of the engine systems it supports.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.