This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

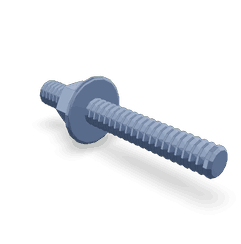

The Studded Flange Cap Screw, identified by Part #5290541, is a component manufactured by Cummins, a renowned name in the automotive and heavy-duty truck industry. This part plays a significant role in the mechanical systems of heavy-duty trucks, contributing to the secure fastening of various components and ensuring the structural integrity of the vehicle.

Basic Concepts

A Studded Flange Cap Screw is a type of fastener characterized by its studded design and flange cap. The studded design allows for a secure fit within threaded holes, while the flange cap provides a broad surface area for distribution of load and torque. Within a truck’s mechanical system, this part functions by securely fastening components, ensuring they remain in place under various operational conditions.

Purpose and Role

The Studded Flange Cap Screw serves a vital function in the operation of a truck. It is primarily used for securing components, such as engine parts, transmission elements, and chassis components. By providing a strong and reliable fastening solution, it helps maintain the structural integrity of the truck, ensuring that components remain securely in place during operation.

Key Features

The Studded Flange Cap Screw boasts several key features that contribute to its functionality. Its studded design allows for a secure fit in threaded holes, while the flange cap provides a broad surface area for load and torque distribution. The material composition of the screw, typically a durable metal alloy, ensures it can withstand the rigors of heavy-duty truck applications.

Benefits

Utilizing a Studded Flange Cap Screw offers several advantages. Its design enhances durability, allowing it to withstand the demanding conditions of heavy-duty truck applications. The broad flange cap improves load distribution, reducing the risk of component failure. Additionally, the screw is designed for ease of installation and removal, facilitating maintenance and repair processes.

Installation Process

Proper installation of the Studded Flange Cap Screw is crucial for ensuring its effectiveness. The process involves selecting the appropriate screw size for the application, using the correct tools for installation, and applying the recommended torque specifications to ensure a secure fit. It is important to follow manufacturer guidelines to prevent damage to the screw or the components being fastened.

Maintenance and Troubleshooting

To ensure the longevity and performance of the Studded Flange Cap Screw, regular maintenance is recommended. This includes checking for signs of wear or damage, ensuring it remains securely fastened, and replacing it if necessary. Common issues may include loosening of the screw or damage to the flange cap, which can often be addressed through re-tightening or replacement.

Safety Considerations

When working with the Studded Flange Cap Screw, it is important to adhere to safety guidelines. This includes proper handling of the screw to prevent injury, using the correct tools and torque specifications during installation, and considering environmental factors that may affect the screw’s performance. Always refer to manufacturer guidelines for specific safety information.

Cummins Overview

Cummins is a well-established manufacturer in the automotive and heavy-duty truck industry, known for its commitment to quality and innovation. With a rich history of producing reliable and high-performance components, Cummins has built a reputation for excellence. Their products, including the Studded Flange Cap Screw, are designed with precision and durability in mind, ensuring they meet the demanding requirements of heavy-duty applications.

Cummins Engine Compatibility with Studded Flange Cap Screw Part 5290541

The Studded Flange Cap Screw part number 5290541, manufactured by Cummins, is designed to fit a variety of Cummins engines, ensuring secure fastening in critical applications. This part is engineered to meet the stringent requirements of Cummins’ engine systems, providing reliable performance and durability.

Engines Compatible with Part 5290541

15N CM2380 M104B

This engine variant is compatible with the Studded Flange Cap Screw part number 5290541. The screw’s design ensures a tight and secure fit, crucial for maintaining the integrity of the engine’s flange connections.

B4.5 CM2350 B129B and B6.7 CM2350 B135B

Both the B4.5 CM2350 B129B and B6.7 CM2350 B135B engines are designed to work seamlessly with the part number 5290541. The studded flange cap screw provides the necessary strength and stability for these engine models, ensuring that flanges remain securely fastened under operational stresses.

F4.5 CM2620 F139B and ISB4.5 CM2350 B104

The F4.5 CM2620 F139B and ISB4.5 CM2350 B104 engines also benefit from the use of the Studded Flange Cap Screw part number 5290541. This screw is integral in maintaining the structural integrity of flange connections, which is vital for the overall performance and longevity of these engines.

ISB6.7 G CM2180 B118

The ISB6.7 G CM2180 B118 engine is another model that is compatible with the part number 5290541. The screw’s studded design ensures a robust fastening solution, critical for the engine’s operation and maintenance.

ISG12 CM2880 G107 and QSG12/X12 CM2350 G110

Lastly, the ISG12 CM2880 G107 and QSG12/X12 CM2350 G110 engines are also designed to work with the Studded Flange Cap Screw part number 5290541. This part’s compatibility with these engines highlights its versatility and importance in securing flange connections across various engine models.

Role of Part 5290541 Studded Flange Cap Screw in Various Engine Systems

Air Compressor

In an air compressor system, the Part 5290541 Studded Flange Cap Screw is instrumental in securing the compressor housing to the mounting bracket. This secure attachment ensures that the compressor operates efficiently by maintaining proper alignment and minimizing vibrations. The studded flange design allows for a robust connection, which is essential for handling the dynamic loads and pressures generated during the compression process. Additionally, the screw’s design facilitates easy maintenance and replacement, ensuring the compressor’s longevity and reliability.

Crankcase Breather

Within the crankcase breather system, the Part 5290541 Studded Flange Cap Screw plays a significant role in attaching the breather housing to the engine block. This connection is vital for managing the pressure within the crankcase, which is essential for maintaining engine lubrication and performance. The screw’s studded flange provides a stable and leak-proof seal, preventing any unwanted air or contaminants from entering the crankcase. This ensures that the breather system functions correctly, contributing to the overall health and efficiency of the engine.

Engine Oil Cooler

In the engine oil cooler system, the Part 5290541 Studded Flange Cap Screw is used to secure the oil cooler to the engine or the vehicle’s chassis. This secure attachment is essential for maintaining the structural integrity of the oil cooler, which is subjected to high temperatures and pressures. The studded flange design of the screw ensures a tight and durable connection, which is crucial for the efficient transfer of heat from the engine oil to the cooling fins. This, in turn, helps in maintaining optimal oil temperature, enhancing engine performance and longevity.

Conclusion

The Studded Flange Cap Screw part number 5290541, manufactured by Cummins, is a critical component in the mechanical systems of heavy-duty trucks and various engine applications. Its design, featuring a studded flange and durable material composition, ensures secure fastening and reliable performance under demanding conditions. Proper installation, maintenance, and adherence to safety guidelines are essential for maximizing the effectiveness and longevity of this part. Its compatibility with a range of Cummins engines underscores its versatility and importance in ensuring the structural integrity and efficiency of engine systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.