5291100

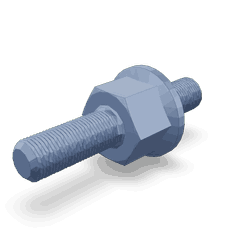

Studded Flange Cap Screw

Cummins®

AVAILABLE

7 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 5291100 Studded Flange Cap Screw is a component manufactured by Cummins, a well-established name in the commercial truck industry. This screw is designed for use in commercial trucks, where it plays a role in securing various parts and assemblies. Its robust construction and precise engineering make it suitable for the demanding conditions encountered in heavy-duty applications 1.

Basic Concepts

A Studded Flange Cap Screw is a type of fastener that combines the features of a cap screw and a flange bolt. It is characterized by a threaded shank that allows it to be screwed into a tapped hole, and a flange at one end that provides a larger bearing surface. This design enables the screw to distribute clamping force more effectively and resist loosening under vibration. In mechanical systems, studded flange cap screws are used to secure components that require a high degree of stability and resistance to dynamic loads 2.

Purpose of the 5291100 Studded Flange Cap Screw

In the operation of a truck, this Cummins part serves to secure critical components and assemblies. It is commonly used in applications where vibration and dynamic loads are present, such as in the engine compartment, transmission, and chassis. By providing a secure and stable connection, this screw helps maintain the integrity of the truck’s mechanical systems, ensuring reliable performance and safety.

Key Features

The 5291100 Studded Flange Cap Screw boasts several key features that enhance its functionality. It is made from high-strength materials, ensuring durability under heavy loads. The threading type is designed to provide a strong grip, while the flange design offers additional resistance to loosening. These attributes make the screw well-suited for the rigors of commercial truck applications.

Benefits

Using the 5291100 Studded Flange Cap Screw offers several advantages. Its durable construction ensures long-term reliability, while its resistance to vibration helps maintain a secure fit in dynamic environments. The screw’s design also facilitates ease of installation, reducing downtime during maintenance procedures. Additionally, its robust nature simplifies maintenance, as it is less likely to require frequent replacement or adjustment.

Installation Process

Proper installation of the 5291100 Studded Flange Cap Screw involves several steps to ensure a secure fit. Begin by cleaning the mating surfaces to remove any debris or contaminants. Use the appropriate tools to insert the screw into the tapped hole, ensuring it is aligned correctly. Tighten the screw to the specified torque setting to achieve the desired clamping force without over-tightening, which could damage the threads or the flange.

Troubleshooting Common Issues

Common issues with the 5291100 Studded Flange Cap Screw may include loosening, corrosion, or damage. To address loosening, check for proper torque settings and ensure the mating surfaces are clean and free of contaminants. Corrosion can be mitigated by applying a suitable anti-corrosion coating or using screws made from corrosion-resistant materials. If damage is detected, replace the screw with a new one to maintain system integrity.

Maintenance Tips

Regular maintenance of the 5291100 Studded Flange Cap Screw can prolong its lifespan and ensure continued reliable performance. Inspect the screw periodically for signs of wear, corrosion, or damage. Clean the mating surfaces as needed to prevent contamination. Apply a light coating of lubricant to the threads to facilitate easy removal during future maintenance procedures. Following these practices will help maintain the screw’s effectiveness in securing critical components.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation for quality and innovation in the commercial truck industry. The company’s product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of heavy-duty applications. Cummins’ commitment to excellence and customer satisfaction has made it a trusted name in the industry.

Studded Flange Cap Screw (Part 5291100) in Cummins Engines

The Studded Flange Cap Screw, identified by part number 5291100, is a critical component in various Cummins engines. This part is designed to secure flanges, ensuring a tight and reliable seal, which is essential for maintaining engine integrity and performance. Here is a detailed look at how this part fits into different Cummins engines:

15N CM2380 M104B, B6.7 CM2350 B135B, ISB (Chrysler), ISB6.7 CM2350 B101

The Studded Flange Cap Screw is used in these engines to secure various flanges, including those on the exhaust system, turbocharger, and other critical components. Its robust design ensures that the flanges remain tightly fastened, preventing leaks and maintaining optimal engine performance.

ISB6.7 G CM2180 B118, ISBE CM2150, ISBE4 CM850

In these engines, the studded flange cap screw is employed to secure flanges on the intake and exhaust systems. The studded design provides a secure grip, which is essential for maintaining the integrity of the engine’s sealing surfaces. This is particularly important in high-stress environments where vibrations and thermal expansion can otherwise cause flanges to loosen.

ISL G CM2180, QSB6.7 CM2250

For the ISL G CM2180 and QSB6.7 CM2250 engines, the studded flange cap screw is used to secure flanges on the turbocharger and other critical components. The studded design ensures that the flanges remain tightly fastened, which is crucial for maintaining the efficiency and reliability of the engine’s turbocharging system.

X12 CM2350 X119B, X12N CMMDG1 X143B, X15 CM2350 X116B

In these engines, the studded flange cap screw is used to secure flanges on the intake and exhaust systems, as well as other critical components. The studded design provides a secure grip, ensuring that the flanges remain tightly fastened and preventing leaks. This is particularly important in engines that operate under high stress and varying conditions.

The studded flange cap screw is a versatile and essential component in Cummins engines, ensuring that flanges remain securely fastened and preventing leaks. Its robust design and secure grip make it a critical part in maintaining the integrity and performance of the engine.

Role of Part 5291100 Studded Flange Cap Screw in Engine Systems

The 5291100 Studded Flange Cap Screw is instrumental in securing and maintaining the integrity of various components within engine systems. Its application spans across multiple areas, ensuring that connections remain tight and secure under operational conditions.

Compressor Air Inlet and Connection

In the compressor air inlet system, the 5291100 screw is used to fasten the flange connections, ensuring a leak-free seal. This is vital for maintaining the efficiency of air compression and preventing any loss of pressurized air, which could affect the overall performance of the compressor.

Water Outlet and Exhaust Recirculation Cooler Kit

For the water outlet and exhaust recirculation cooler kit, the 5291100 screw plays a significant role in securing the plumbing connections. This ensures that coolant and recirculated exhaust gases are properly managed, contributing to the effective cooling of engine components and reducing emissions.

Hardware Kit and Harness

Within the hardware kit, the 5291100 screw is often utilized to secure various brackets and mounts. Additionally, in the harness assembly, it helps in fastening electronic control module wiring, ensuring that all connections are stable and resistant to vibration, which is common in engine environments.

Manifold and Exhaust

In the manifold and exhaust systems, the 5291100 screw is employed to secure flanges and connections, ensuring that exhaust gases are directed efficiently without leaks. This not only enhances engine performance but also ensures that emissions are properly managed.

Engine Control and Plumbing

For engine control modules and plumbing systems, the 5291100 screw is essential in maintaining the integrity of connections related to compressor coolant, exhaust recirculation air, and exhaust recirculation water. This ensures that all fluid dynamics within the engine are optimally managed, contributing to both performance and durability.

Recirculation and Exhaust

Finally, in recirculation systems, the 5291100 screw helps in securing components that manage the flow of recirculated exhaust gases. This is important for reducing emissions and improving fuel efficiency, as well as for maintaining the overall health of the engine by ensuring that all recirculated gases are properly handled.

Conclusion

The 5291100 Studded Flange Cap Screw is a critical component in the maintenance and operation of commercial trucks and Cummins engines. Its robust design, resistance to vibration, and ease of installation make it an invaluable part in securing various components and assemblies. Regular maintenance and proper installation are essential to ensure the longevity and reliability of this part, contributing to the overall performance and safety of the vehicle.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.