This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

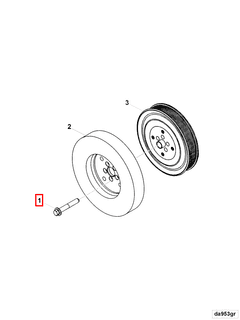

The Hexagon Flange Head Cap Screw, identified by part number 5292779, is a specialized fastener produced by Cummins, a renowned manufacturer in the heavy-duty truck industry. This screw is designed to meet the rigorous demands of heavy-duty truck applications. Its unique design and robust construction make it suitable for various fastening needs within the automotive sector. The screw’s hexagonal head and flange design contribute to its effectiveness and reliability in securing components under significant stress and vibration.

Basic Concepts

The Hexagon Flange Head Cap Screw is engineered with a specific structure that includes a hexagonal head and a flanged base. The hexagonal head allows for efficient torque application using standard tools, while the flange provides additional surface area for load distribution and resistance to rotation. Typically, these screws are made from high-strength materials such as alloy steel, which ensures durability and resistance to wear and corrosion. The flange head design offers several advantages, including improved grip on the fastened material and enhanced stability during operation 1.

Purpose and Role in Truck Operation

In heavy-duty trucks, the Hexagon Flange Head Cap Screw plays a significant role in securing various components and systems. It is commonly used in applications where high torque and secure fastening are required, such as in engine assemblies, transmission systems, and chassis components. The screw’s design ensures that it can withstand the dynamic loads and vibrations inherent in truck operation, maintaining secure fastening over time.

Key Features

Several key features contribute to the effectiveness of the Hexagon Flange Head Cap Screw. The hexagonal head allows for precise torque application, reducing the risk of over-tightening or stripping. The flange design provides additional surface area, which enhances load distribution and prevents the screw from rotating during operation. The material properties, typically high-strength alloy steel, ensure durability and resistance to corrosion, making it suitable for demanding environments. These features collectively contribute to the screw’s reliability and longevity in truck applications 2.

Benefits

Using the Hexagon Flange Head Cap Screw in truck maintenance and assembly offers several benefits. The design allows for enhanced torque application, ensuring that components are securely fastened without the risk of damage. The flange provides improved load distribution, reducing stress on the fastened material and enhancing overall stability. Additionally, the screw’s resistance to loosening and corrosion ensures reliable performance over the lifespan of the truck, minimizing the need for frequent maintenance.

Installation and Usage

Proper installation of the Hexagon Flange Head Cap Screw is critical to ensure secure fastening and longevity. It is recommended to use the appropriate torque wrench to apply the specified torque, avoiding over-tightening which can lead to damage. The screw should be installed in a clean, dry environment to prevent corrosion. Common applications within truck assemblies include securing engine components, transmission parts, and chassis elements where high torque and secure fastening are required.

Troubleshooting and Maintenance

To ensure the longevity and reliable performance of the Hexagon Flange Head Cap Screw, regular maintenance and troubleshooting are necessary. Common issues such as loosening or corrosion can be addressed by periodically checking the torque and ensuring that the screw remains securely fastened. If corrosion is detected, it is advisable to clean the affected area and apply a suitable anti-corrosion treatment. Regular inspections and maintenance will help prevent issues and ensure the screw continues to perform effectively.

Cummins: Manufacturer Overview

Cummins Inc. is a leading manufacturer known for its high-quality automotive components, including the Hexagon Flange Head Cap Screw. With a strong reputation for innovation and reliability, Cummins has established itself as a trusted name in the heavy-duty truck industry. The company’s commitment to producing durable and efficient components ensures that their products meet the demanding requirements of heavy-duty applications, providing customers with reliable and long-lasting solutions 3.

Cummins Hexagon Flange Head Cap Screw Part 5292779 in Engine Applications

The Cummins part number 5292779, a Hexagon Flange Head Cap Screw, is a critical component in the assembly and maintenance of various Cummins engines. This screw is designed to provide secure fastening in high-stress environments, ensuring the integrity and performance of the engine systems.

ISL G CM2180 Engines

In the ISL G CM2180 engines, the Hexagon Flange Head Cap Screw part 5292779 is utilized in several key areas. It is often employed in securing components that require robust fastening, such as engine mounts, brackets, and various housings. The screw’s design allows for precise torque application, which is essential for maintaining the alignment and stability of these parts under operational conditions.

Grouping of Engine Applications

The part 5292779 is not limited to a single engine model but is integral to the assembly of multiple Cummins engines. Its application extends across various engine groups where high-strength fastening is necessary. This includes securing critical engine components in both the ISL G CM2180 and other similar engine models, ensuring that these parts remain tightly fastened and properly aligned during operation.

Role of Part 5292779 Hexagon Flange Head Cap Screw in Engine Systems

The part 5292779 Hexagon Flange Head Cap Screw is instrumental in ensuring the secure assembly and reliable operation of various engine components. Its design allows for a robust connection, which is essential in environments where vibrations and dynamic loads are prevalent.

Integration with Dampers

In engine systems, dampers are employed to absorb and reduce vibrations, ensuring smoother operation and prolonging the lifespan of connected components. The Hexagon Flange Head Cap Screw plays a significant role here by providing a stable and firm attachment point for dampers to the engine block or other structural elements. This secure fastening helps maintain the damper’s effectiveness over time, even under the constant stress of engine vibrations.

Vibration Management

Engines inherently produce vibrations during operation, which, if not properly managed, can lead to increased wear and potential failure of components. The Hexagon Flange Head Cap Screw contributes to vibration management by ensuring that all bolted connections remain tight and secure. This is particularly important for components that are directly exposed to engine vibrations, such as mounting brackets, sensor housings, and ancillary equipment.

By maintaining a consistent and reliable connection, the screw helps in minimizing the transfer of unwanted vibrations to sensitive engine parts, thereby enhancing overall engine performance and durability.

Conclusion

The Hexagon Flange Head Cap Screw (part number 5292779) by Cummins is a vital component in the heavy-duty truck industry, offering robust fastening solutions for various applications. Its unique design, high-strength material, and reliable performance make it an essential part in securing critical components in engine assemblies, transmission systems, and chassis elements. Proper installation, regular maintenance, and understanding its role in vibration management contribute to the longevity and efficiency of heavy-duty trucks.

-

Watson, B. (2011). Mobile Equipment Hydraulics A Systems and Troubleshooting Approach. Cengage Learning.

↩ -

Bonneau, D., Fatu, A., & Souchet, D. (2014). Internal Combustion Engine Bearings Lubrication in Hydrodynamic Bearings. Wiley-ISTE.

↩ -

Zhao, H. (2010). Advanced Direct Injection Combustion Engine Technologies and Development Volume 2 Diesel Engines. CRC Press.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.