This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

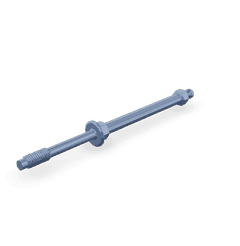

The 5296000 Round Head Cap Screw is a specialized fastener designed by Cummins for use in commercial trucks. This screw is integral to the assembly and maintenance of various truck components, ensuring secure and reliable connections in demanding environments.

Basic Concepts of Round Head Cap Screws

A Round Head Cap Screw is a type of fastener characterized by its rounded head and threaded shaft. It is commonly used in mechanical assemblies to secure components together. The rounded head provides a larger surface area for distribution of clamping force, reducing the risk of damage to the fastened material. Additionally, the head design allows for easy installation and removal using standard tools 1.

Purpose of the 5296000 Round Head Cap Screw in Truck Operations

The 5296000 Round Head Cap Screw plays a significant role in the operation and maintenance of commercial trucks. It is utilized in various truck systems, including the engine, transmission, and chassis. By securely fastening components, it ensures the structural integrity and performance of these systems. Its applications range from attaching engine covers to securing critical chassis components, contributing to the overall reliability of the truck 2.

Key Features of the 5296000 Round Head Cap Screw

The 5296000 Round Head Cap Screw is engineered with specific design and manufacturing specifications to meet the rigorous demands of commercial truck applications. It is typically made from high-strength steel, offering durability and resistance to wear. The screw features a fine thread, which provides a strong grip and reduces the likelihood of loosening under vibration. The rounded head is designed to distribute clamping force evenly, minimizing the risk of damage to the fastened material 3.

Benefits of Using the 5296000 Round Head Cap Screw

The 5296000 Round Head Cap Screw offers several advantages for commercial truck applications. Its high-strength material composition ensures durability and longevity, even under heavy loads and harsh conditions. The fine thread design enhances its resistance to loosening, maintaining secure connections over time. Additionally, the rounded head facilitates easy installation and removal, reducing maintenance time and effort 4.

Installation Guidelines

Proper installation of the 5296000 Round Head Cap Screw is crucial for optimal performance and longevity. To install the screw, begin by ensuring the mating surfaces are clean and free of debris. Use a torque wrench to tighten the screw to the manufacturer’s specified torque settings, avoiding over-tightening which can lead to damage. It is also recommended to apply a thread locker to prevent loosening due to vibration.

Troubleshooting Common Issues

Common issues associated with Round Head Cap Screws include loosening and corrosion. To address loosening, ensure the screw is properly torqued during installation and consider using a thread locker. If corrosion is observed, clean the affected area thoroughly and apply a corrosion-resistant coating to prevent further degradation. Regular inspection and maintenance can help identify and resolve these issues promptly.

Maintenance Tips

Regular maintenance practices can prolong the life of the 5296000 Round Head Cap Screw. Inspect the screws periodically for signs of wear, corrosion, or loosening. Replace any screws that show significant damage or degradation. Additionally, ensure that all mating surfaces remain clean and free of debris to maintain optimal performance.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is committed to quality, innovation, and customer satisfaction. The company’s product range includes engines for on-highway and off-highway applications, as well as filtration and power generation solutions. Cummins’ dedication to excellence is evident in its rigorous testing and quality control processes, ensuring that its products meet the highest standards of performance and reliability.

Cummins Part 5296000: Round Head Cap Screw in Engine Applications

The Cummins part 5296000, a Round Head Cap Screw, is a critical component in the assembly and maintenance of several engine models. This part is integral to the structural integrity and operational efficiency of the engines it is used in.

Application in ISF2.8 CM2220 Engines

The Round Head Cap Screw is used in the ISF2.8 CM2220 F117 and ISF2.8 CM2220 F129 engines. These engines are known for their reliability and performance in various applications. The screw is employed in securing various engine components, ensuring that they remain tightly fastened and properly aligned during operation. This is crucial for maintaining the engine’s performance and longevity.

Application in R2.8 CM2220 R101B Engine

Similarly, in the R2.8 CM2220 R101B engine, the Round Head Cap Screw plays a vital role. It is used to secure key engine parts, ensuring that they are held firmly in place under the high stresses and vibrations typical of engine operation. This helps in preventing any potential loosening or misalignment that could lead to engine failure or reduced efficiency.

Common Usage Across Models

Across these engine models, the Round Head Cap Screw is utilized in several critical areas. It is often found in the engine block, cylinder head, and other structural components where it provides the necessary fastening to keep the engine together. The screw’s design, with its round head and threaded shaft, allows for easy installation and removal, making it a preferred choice for maintenance and repair work.

The use of the Round Head Cap Screw in these engines underscores its importance in ensuring the engines’ structural integrity and operational efficiency. Its consistent application across different engine models highlights its versatility and reliability in demanding environments.

Part 5296000 Round Head Cap Screw Component Usage

The part 5296000 Round Head Cap Screw is integral to the assembly and maintenance of various engine components, ensuring secure fastening and reliable performance.

In the context of engine covers, the Round Head Cap Screw is utilized to fasten the cover securely to the engine block. This ensures that the cover remains in place under operational conditions, protecting internal components from contaminants and maintaining the engine’s integrity. The screw’s design allows for easy installation and removal, facilitating routine maintenance and inspections.

For valve covers, the Round Head Cap Screw plays a similar role. It secures the valve cover to the cylinder head, creating a seal that prevents oil leaks and maintains the proper pressure within the valve train. This is essential for the efficient operation of the valve system, which is responsible for the intake and exhaust processes in the engine.

In applications involving valve assemblies, the Round Head Cap Screw is often used to secure various components within the valve train. This includes fastening valve springs, retainers, and other accessories that are critical to the valve’s function. The screw’s robust design ensures that these components remain in place under the high stresses and vibrations experienced during engine operation.

Overall, the part 5296000 Round Head Cap Screw is a versatile fastener that contributes to the secure assembly and reliable performance of multiple engine components. Its application in covers and valve systems underscores its importance in maintaining the structural and functional integrity of the engine.

Conclusion

The 5296000 Round Head Cap Screw is a critical component in the assembly and maintenance of commercial truck engines. Its design and features ensure secure fastening, durability, and ease of maintenance. Proper installation and regular maintenance are essential to maximize its performance and longevity. Cummins’ commitment to quality and innovation is reflected in the design and application of this part, ensuring the reliability and efficiency of the engines it is used in.

-

Hilgers, Michael. Entire Vehicle: Second Edition. Springer Nature, 2023.

↩ -

Kasab, John, and Andrea Strzelec. Automotive Emissions Regulations and Exhaust Aftertreatment Systems. SAE International, 2020.

↩ -

Lakshminarayanan, P. A., and Avinash Kumar Agarwal. Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer, 2019.

↩ -

Bennett, Sean. Modern Diesel Technology: Light Duty Diesels. Cengage Learning, 2012.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.