This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 5301264 Studded Hexagon Cap Screw is a specialized fastener produced by Cummins, a well-established manufacturer in the commercial truck industry. This screw is designed for use in commercial trucks, where it contributes to the secure assembly of various components. Cummins is renowned for its commitment to quality and innovation, ensuring that their products meet the demanding requirements of heavy-duty applications 1.

Basic Concepts of Studded Hexagon Cap Screws

A studded hexagon cap screw is a type of fastener characterized by a hexagonal head and a threaded shank that extends beyond the nut or tapped hole it secures. This design allows for easy tightening and loosening using a wrench or socket. In mechanical applications, these screws are used to join components securely, providing a strong and reliable connection. They function by converting torque applied to the head into clamping force, which holds the joined parts together 2.

Role and Function in Truck Operation

The 5301264 Studded Hexagon Cap Screw plays a significant role in the operation and maintenance of commercial trucks. It is utilized in various application areas, including engine components, chassis assemblies, and other critical systems. By providing a secure and stable connection, this screw helps ensure the structural integrity and performance of the truck. Its reliable fastening capability is vital for maintaining the safety and efficiency of the vehicle under demanding conditions 3.

Key Features

The 5301264 Studded Hexagon Cap Screw boasts several key features that enhance its functionality and durability. Its design includes a hexagonal head for easy engagement with tools, a shank with precise threading for secure fastening, and a studded end that extends beyond the nut or tapped hole. The material composition typically includes high-strength steel, which provides excellent resistance to wear and corrosion. These attributes contribute to the screw’s ability to withstand the rigors of heavy-duty truck applications.

Benefits

The 5301264 Studded Hexagon Cap Screw offers numerous benefits that make it an ideal choice for commercial truck applications. Improved load distribution is achieved through its secure fastening, which helps prevent component misalignment and failure. Enhanced fastening security ensures that the joined parts remain firmly in place, even under dynamic loads and vibrations. Additionally, the screw’s resistance to vibration and longevity in harsh operating conditions contribute to its reliability and durability.

Installation Considerations

Proper installation of the 5301264 Studded Hexagon Cap Screw is crucial for ensuring a secure and effective fit. Guidelines and best practices include using the correct torque specifications to avoid over-tightening or under-tightening, which can lead to damage or loosening. Recommended tools, such as wrenches or sockets that match the screw’s hexagonal head, should be used to apply the appropriate torque. Following these steps will help achieve a reliable and durable connection.

Troubleshooting and Maintenance

Common issues that may arise with studded hexagon cap screws include loosening, corrosion, or damage. Troubleshooting steps may involve re-tightening the screw to the specified torque, inspecting for signs of corrosion or wear, and replacing the screw if necessary. Maintenance tips to prolong the lifespan of the screw include regular inspection for signs of wear or damage, ensuring proper torque is maintained, and protecting the screw from corrosive environments to prevent degradation.

Cummins: Manufacturer Overview

Cummins Inc. is a leading manufacturer in the automotive industry, with a strong reputation for quality and innovation. Founded in 1919, Cummins has a long history of producing reliable and high-performance components for commercial trucks and other heavy-duty applications. The company’s commitment to excellence is evident in its rigorous manufacturing processes, extensive research and development efforts, and dedication to customer satisfaction. Cummins’ products, including the 5301264 Studded Hexagon Cap Screw, are designed to meet the demanding requirements of the commercial truck industry, ensuring durability, performance, and reliability.

Integration of Studded Hexagon Cap Screw 5301264 in Cummins Engines

The Studded Hexagon Cap Screw 5301264, manufactured by Cummins, is a critical component in the assembly and maintenance of several Cummins engine models. This part is integral to ensuring the structural integrity and operational efficiency of the engines.

Cummins 4B3.9 and 6B5.9 Engines

In the Cummins 4B3.9 and 6B5.9 engines, the 5301264 screw is utilized in various applications where secure fastening is essential. These engines, known for their robust performance, require reliable components to maintain their operational standards. The studded hexagon cap screw is often employed in areas where high torque and durability are necessary, such as in the engine block, cylinder head, and other critical assemblies.

Cummins X12 CM2350 X119B Engine

For the Cummins X12 CM2350 X119B engine, the 5301264 screw is similarly vital. This engine, designed for heavy-duty applications, demands components that can withstand significant stress and pressure. The studded hexagon cap screw is used extensively in the engine’s construction to ensure that all parts are tightly secured, preventing any potential loosening or failure during operation. Its application spans across various engine components, including the engine block, turbo housing, and other critical assemblies.

The use of the 5301264 screw in these engines underscores its importance in maintaining the structural integrity and performance of Cummins engines. Its design and material properties make it an ideal choice for the demanding environments these engines operate in.

Part 5301264 Studded Hexagon Cap Screw Component Usage

The Part 5301264 Studded Hexagon Cap Screw is instrumental in ensuring the secure assembly and reliable operation of various engine components.

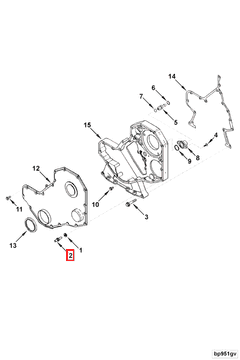

In the cover assembly, this screw plays a significant role in maintaining the integrity of the seal. It ensures that the cover remains firmly attached, preventing any potential leaks or misalignments that could compromise engine performance.

For the front gear, the studded hexagon cap screw is used to secure the gear in place. This is essential for maintaining the precise alignment and smooth operation of the gear, which is vital for the efficient transfer of power within the engine.

In the recirculation system, this screw helps in securing components that are part of the recirculation process. Proper fastening ensures that these parts function correctly, contributing to the overall efficiency and longevity of the engine.

Lastly, in the exhaust system, the Part 5301264 screw is utilized to secure exhaust components. This ensures that the exhaust system remains intact, reducing the risk of emissions leaks and maintaining the engine’s performance and environmental compliance.

Conclusion

The 5301264 Studded Hexagon Cap Screw is a vital component in the assembly and maintenance of commercial trucks and Cummins engines. Its design, material properties, and reliable fastening capability make it an ideal choice for heavy-duty applications. Proper installation, maintenance, and troubleshooting are essential to ensure the longevity and performance of this critical fastener.

-

Giancarlo Genta and Lorenzo Morello, The Automotive Chassis Volume 1 Components Design Mechanical Engineering Series 2nd Edition, Springer, 2019.

↩ -

Michael Trzesniowski, The Complete Vehicle, Springer Nature, 2023.

↩ -

Haoran Hu, Rudy Smaling, Simon Baseley, Heavy-Duty Wheeled Vehicles, SAE International, 2014.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.