This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

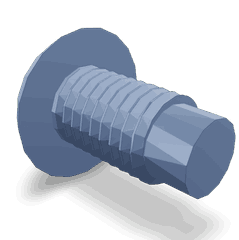

The Cummins 5304497 Drive Screw is a specialized component designed for use in commercial trucks. It serves a specific function within the truck’s mechanical system, contributing to the overall efficiency and reliability of the vehicle. Understanding its purpose and role is fundamental for maintaining and optimizing truck performance.

Basic Concepts of Drive Screws

A drive screw, also known as a lead screw or power screw, is a mechanical component that converts rotational motion into linear motion. It consists of a screw thread cut along the circumference of a cylinder, which engages with a corresponding nut. In automotive applications, drive screws are used in various systems to transmit force and motion, playing a role in mechanisms such as gear shifts, valve operations, and other functions 1.

Purpose of the 5304497 Drive Screw

The Cummins 5304497 Drive Screw is integral to the operation of commercial trucks. It functions within the truck’s mechanical system to facilitate the conversion of rotational motion into linear motion, which is necessary for the operation of certain components. Its role ensures that specific parts of the truck can move or adjust as required for optimal performance.

Key Features

The Cummins 5304497 Drive Screw is characterized by several key features that enhance its functionality and durability. It is constructed from high-quality materials, ensuring resistance to wear and corrosion. The design includes precise threading and a robust structure, which allows it to withstand significant loads and stresses. These features contribute to its reliability and efficiency in demanding commercial truck applications 2.

Benefits

Utilizing the Cummins 5304497 Drive Screw offers several advantages. Its durable construction ensures longevity, reducing the need for frequent replacements. The efficient design of the screw contributes to the overall performance of the truck, enhancing operational reliability. Additionally, its compatibility with specific truck models ensures seamless integration into the vehicle’s mechanical system 3.

Installation and Usage

Proper installation of the Cummins 5304497 Drive Screw is crucial for ensuring optimal performance. It should be installed according to the manufacturer’s guidelines, which may include specific torque settings and alignment requirements. Regular checks and maintenance are recommended to ensure that the screw remains in good condition and continues to function effectively within the truck’s system.

Troubleshooting and Maintenance

Common issues with the Cummins 5304497 Drive Screw may include wear, misalignment, or damage to the threading. Regular inspections can help identify these problems early, allowing for timely repairs or replacements. Maintenance tips include keeping the screw clean and free from debris, ensuring proper lubrication, and monitoring for signs of wear or damage that may affect its performance.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-performance components. The company’s extensive product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of commercial vehicles.

Role of Part 5304497 Drive Screw in Engine Systems

The 5304497 Drive Screw is integral to the functionality and efficiency of various engine components. Its primary role is to ensure secure and precise fastening, which is essential for the optimal performance of the engine.

Valve Cover Assembly

In the valve cover assembly, the 5304497 Drive Screw plays a significant role in maintaining a tight seal. This seal is vital for preventing oil leaks and ensuring that the valve cover remains securely attached to the engine block. The screw’s design allows for easy adjustment and re-torquing, which is necessary during maintenance or repair procedures.

Long Block Integration

When integrating the drive screw into the long block, it ensures that all components within the engine block are held firmly in place. This is particularly important for the crankshaft and camshaft, where precise alignment and secure fastening are required to prevent engine misfires and other performance issues. The drive screw’s robust construction helps withstand the high torque and vibrations generated during engine operation.

Agency Approval and Arrangement

For components that require agency approval, the 5304497 Drive Screw is often specified due to its reliability and consistency. Its use in the arrangement of various engine parts ensures that all elements are correctly positioned and fastened, which is essential for meeting regulatory standards and achieving agency approval. This screw is frequently employed in critical junctions where failure is not an option.

Overall Engine Performance

The consistent use of the 5304497 Drive Screw across different engine components contributes to the overall stability and performance of the engine. By providing a secure and reliable fastening solution, it helps maintain the integrity of the engine’s structure, ensuring that all parts work in harmony. This, in turn, leads to improved engine efficiency, reduced wear and tear, and extended component lifespan.

Conclusion

The Cummins 5304497 Drive Screw is a critical component in the operation of commercial trucks and various engine systems. Its role in ensuring secure and precise fastening contributes to the overall efficiency and reliability of the vehicle. Proper installation, regular maintenance, and understanding its key features and benefits are essential for optimizing truck and engine performance.

-

Thorsten Boger, Willard Cutler, “Reducing Particulate Emissions in Gasoline Engines,” SAE International, 2018.

↩ -

Hermann Hiereth, Peter Prenninger, and Klaus W Drexl, “Charging the Internal Combustion Engine,” Springer, 2010.

↩ -

Karsten Berns, Klaus Dressler, Patrick Fleischmann, Daniel Grges, Ralf Kalmar, Bernd Sauer, Nicole Stephan, Roman Teutsch, Martin Thul, “Proceedings of the 5th Commercial Vehicle Technology Symposium CVT,” Springer, 2018.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.