This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Studded Flange Cap Screw, Part #5311308 by Cummins, is a specialized fastener designed for heavy-duty truck applications. Cummins, a renowned manufacturer in the commercial vehicle industry, produces this component to meet the demanding requirements of truck operations. This screw plays a role in ensuring the secure assembly of various truck components, contributing to the overall reliability and performance of the vehicle.

Basic Concepts of Studded Flange Cap Screws

Studded flange cap screws are a type of fastener used in mechanical assemblies to secure components together. They feature a threaded shank and a flanged head, which provides a larger bearing surface and helps distribute the load more evenly across the fastened parts. These screws are commonly used in applications where high tensile strength and resistance to vibration are required. They function by threading into a pre-tapped hole and tightening to create a secure connection between components 1.

Purpose of the 5311308 Studded Flange Cap Screw in Truck Operations

This Cummins part is specifically designed for use in commercial trucks. It plays a role in securing critical components, such as engine parts, transmission assemblies, and chassis elements. Its application areas include fastening engine blocks, securing transmission housings, and attaching various brackets and supports. The functional importance of this screw lies in its ability to provide a strong, vibration-resistant connection that ensures the integrity of the truck’s mechanical systems 2.

Key Features of the 5311308 Studded Flange Cap Screw

The Studded Flange Cap Screw boasts several distinctive characteristics that enhance its performance and durability. It is made from high-strength materials, typically alloy steel, which provides excellent tensile strength and resistance to wear. The screw features a coarse threading type, which allows for quick and secure fastening. Its flanged head design offers a larger bearing surface, improving load distribution and reducing the risk of component damage. Additionally, the screw is designed with precision to ensure compatibility with various truck models and applications 3.

Benefits of Using the 5311308 Studded Flange Cap Screw

Using this part offers several advantages. The screw’s high-strength material composition and coarse threading type contribute to improved load distribution and enhanced security of fastened components. Its flanged head design provides additional stability and resistance to vibration, which is crucial in the dynamic environment of truck operations. Furthermore, the screw’s durable construction ensures long-term performance and reliability, even under harsh environmental conditions.

Installation and Usage Guidelines

Proper installation of the 5311308 Studded Flange Cap Screw is vital to ensure optimal performance and longevity. Begin by selecting the appropriate hole size and ensuring it is clean and free of debris. Thread the screw into the pre-tapped hole by hand to avoid cross-threading. Use a torque wrench to tighten the screw to the manufacturer’s specified torque value, which ensures a secure connection without over-tightening. Regularly inspect the screw for signs of wear or damage and replace it if necessary to maintain the integrity of the fastened components.

Troubleshooting Common Issues

Frequent problems associated with studded flange cap screws include loosening and corrosion. To address loosening, ensure that the screw is properly torqued during installation and periodically check for any signs of movement. If corrosion is detected, clean the affected area thoroughly and apply a suitable anti-corrosion coating to prevent further degradation. In some cases, replacing the screw may be necessary to maintain the security of the fastened components.

Maintenance Tips

Regular maintenance practices can prolong the service life of the 5311308 Studded Flange Cap Screw. Inspect the screw periodically for signs of wear, corrosion, or damage. Clean the screw and surrounding area to remove any dirt or debris that could contribute to corrosion. Apply a protective coating if necessary to enhance resistance to environmental factors. When replacing the screw, ensure that the new component meets the same specifications and quality standards as the original to maintain the integrity of the truck’s mechanical systems.

Compatibility of Studded Flange Cap Screw (Part 5311308) with Cummins Engines

The Studded Flange Cap Screw (Part 5311308) manufactured by Cummins is designed to fit seamlessly with several of their engine models. This part is crucial for securing flanges and ensuring a tight seal, which is vital for the operational integrity of the engines. Below are the Cummins engines that are compatible with this specific part:

- ISD4.5 CM2220 D108

- ISG12 G CMOH6.0 G111

These engines, while differing in specifications and applications, share a commonality in their requirement for reliable fastening solutions. The Studded Flange Cap Screw (Part 5311308) is engineered to meet the stringent demands of these engines, providing durability and ease of installation. Its design ensures that it can withstand the operational stresses and environmental conditions these engines are subjected to, thereby enhancing the overall performance and longevity of the engine systems.

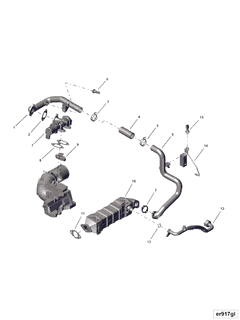

Role of Part 5311308 Studded Flange Cap Screw in Engine Systems

The 5311308 studded flange cap screw is a component in securing various parts within engine systems. Its primary function is to provide a robust and reliable fastening solution that ensures the integrity and stability of the engine’s structural and functional elements.

Block and Cylinder Assembly

In the engine block and cylinder assembly, the 5311308 studded flange cap screw is used to secure the cylinder head to the engine block. This connection is vital for maintaining the seal between the cylinder and the head, ensuring that combustion pressures are contained effectively. The screw’s design allows for precise torque application, which is necessary for achieving the correct clamping force without over-tightening, thus preventing damage to the gaskets and surfaces.

Cover Attachments

For engine covers, such as valve covers or timing chain covers, the 5311308 studded flange cap screw offers a secure attachment point. These covers protect internal components from contaminants and help maintain the engine’s cleanliness. The screw’s studded flange provides additional surface area for better load distribution, reducing the risk of stripping or pulling through the cover material.

Fuel Pump and Manifold Connections

In fuel pump assemblies, the 5311308 screw is often used to attach the fuel pump to the engine block or fuel system components. This ensures a stable and leak-free connection, which is essential for the proper delivery of fuel to the engine. Similarly, in manifold applications, whether intake or exhaust, the screw secures the manifold to the engine block or cylinder head, ensuring a tight seal that prevents air or exhaust leaks, which can affect engine performance and emissions.

Exhaust System Integration

Within the exhaust system, the 5311308 studded flange cap screw plays a role in attaching exhaust manifolds to the engine block and connecting various exhaust components. Its robust design withstands the high temperatures and vibrations typical in exhaust systems, ensuring a durable and reliable connection. Additionally, in exhaust recirculation systems, the screw secures components that reroute exhaust gases back into the intake tract, helping to reduce emissions and improve fuel efficiency.

Conclusion

Overall, the 5311308 studded flange cap screw is a versatile and reliable fastening solution that contributes to the structural integrity and functional performance of various engine components. Its high-strength material, coarse threading, and flanged head design make it suitable for demanding applications in commercial trucks and engine systems. Proper installation, maintenance, and troubleshooting practices are essential to ensure the longevity and reliability of this critical component.

-

Dixon, John. Modern Diesel Technology: Heating, Ventilation, Air Conditioning, Refrigeration, 2nd Edition. Cengage Learning, 2014.

↩ -

Caines, Arthur J., Haycock, Roger F., & Hillier, John E. Automotive Lubricants Reference Book. SAE International, 2004.

↩ -

Duffy, Owen C., & Wright, Gus. Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems. Jones Bartlett Learning, 2016.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.