This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

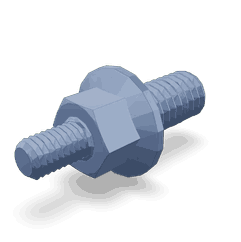

The Studded Flange Cap Screw, identified by part number 5320537, is a specialized fastener utilized in heavy-duty truck applications. Manufactured by Cummins, a renowned name in the automotive and heavy-duty truck industry, this component is integral to ensuring the secure assembly of various truck components. Cummins is recognized for its commitment to quality and innovation, making the 5320537 Studded Flange Cap Screw a reliable choice for truck maintenance and operation 1.

Basic Concepts

A Studded Flange Cap Screw is a type of fastener that combines the features of a stud and a flanged bolt. It is designed to provide a secure and stable connection in mechanical systems. The screw features a threaded stud that passes through pre-drilled holes in the components being joined, and a flange at one end that distributes the clamping force over a larger area, enhancing the stability of the connection. This type of fastener is commonly used in applications where high tensile strength and resistance to vibration are required 2.

Purpose of the 5320537 Studded Flange Cap Screw

This part plays a specific role in the operation of heavy-duty trucks. It is utilized in various truck components where secure and durable fastening is necessary. This includes applications in the engine assembly, transmission systems, and other critical areas where components are subjected to significant stress and vibration. The screw ensures that parts remain firmly in place, contributing to the overall reliability and performance of the truck 3.

Key Features

The 5320537 Studded Flange Cap Screw is characterized by several primary features that enhance its performance. Its design includes a robust threaded stud and a wide flange that provides additional surface area for clamping. The material composition typically consists of high-strength steel, which offers excellent durability and resistance to wear and tear. Additionally, the screw may feature coatings or treatments that improve corrosion resistance, ensuring longevity in various operating conditions.

Benefits

Using this Cummins part offers several advantages. Its high tensile strength and resistance to vibration make it ideal for heavy-duty applications. The flanged design enhances the stability of the connection, reducing the risk of loosening over time. Furthermore, the durable material composition ensures long-lasting performance, minimizing the need for frequent replacements. These factors contribute to improved efficiency in truck maintenance and operation.

Installation Process

Proper installation of the 5320537 Studded Flange Cap Screw is crucial for optimal performance and longevity. The installation process involves the following steps:

- Ensure that the components to be joined are properly aligned and that the holes are clean and free of debris.

- Insert the threaded stud through the pre-drilled holes in the components.

- Use a compatible nut to secure the screw in place, ensuring that the flange is positioned against the surface of the component.

- Tighten the nut to the recommended torque specification to achieve the proper clamping force without over-tightening, which could damage the components or the screw.

Troubleshooting and Maintenance

To ensure the continued reliable operation of the 5320537 Studded Flange Cap Screw, regular maintenance and troubleshooting are necessary. Common issues may include loosening due to vibration or corrosion. Regular inspections should be conducted to check for signs of wear or damage. If corrosion is detected, cleaning the affected areas and applying a corrosion-resistant coating can help prolong the lifespan of the screw. Additionally, ensuring that the screw is properly torqued during installation and re-tightening it periodically can prevent loosening.

Cummins: Manufacturer Overview

Cummins is a well-established manufacturer with a strong reputation in the automotive and heavy-duty truck industry. Founded in 1919, Cummins has a long history of innovation and quality in producing engine and powertrain components. The company is committed to delivering reliable and high-performance products that meet the demanding requirements of heavy-duty applications. Cummins’ dedication to research and development ensures that their components, including the 5320537 Studded Flange Cap Screw, continue to evolve and provide superior performance in the field.

Cummins Engine Part 5320537: Studded Flange Cap Screw

The Studded Flange Cap Screw, part number 5320537, manufactured by Cummins, is a critical component in the assembly of various Cummins engines. This part is designed to secure flanges and other components, ensuring a tight and reliable connection. Here’s how it fits into the specified engines:

L9 CM2670 L128B and L9.3 L105 Engines

For the L9 CM2670 L128B and L9.3 L105 engines, the Studded Flange Cap Screw is utilized in several key areas:

- Cylinder Head to Block Connection: This screw is often used to fasten the cylinder head to the engine block, ensuring a secure seal and preventing leaks.

- Exhaust Manifold Attachment: It is also employed to attach the exhaust manifold to the engine, maintaining the integrity of the exhaust system.

- Oil Pan Fastening: The screw can be used to secure the oil pan to the engine block, ensuring that the oil is contained within the system.

These applications highlight the importance of the Studded Flange Cap Screw in maintaining the structural integrity and operational efficiency of the engines. Its design, which includes studs that provide additional strength and resistance to loosening, makes it a reliable choice for these critical connections.

Role of Part 5320537 Studded Flange Cap Screw in Engine Systems

Integration with the Cylinder Block Kit

The 5320537 studded flange cap screw is instrumental in securing various components within the cylinder block kit. This screw ensures that the cylinder block remains intact and properly aligned, which is essential for the engine’s overall performance. By fastening critical elements such as cylinder liners, piston assemblies, and other internal components, it maintains the structural integrity of the cylinder block. This, in turn, allows for efficient combustion and power generation within the engine.

Contribution to the Arrangement of Engine Components

In the arrangement of engine components, the 5320537 studded flange cap screw plays a significant role. It is used to secure gaskets, spacers, and other intermediary parts that are essential for the proper alignment and sealing of engine components. This screw helps in maintaining the precise distances and alignments required between moving parts, which is vital for the smooth operation of the engine. Its robust design ensures that these components remain in place under the high stresses and vibrations typical in engine operation.

Importance in Lifting and Handling

During the lifting and handling of engine components, the 5320537 studded flange cap screw provides a secure attachment point. Whether it is for maintenance, repair, or installation, this screw ensures that components are safely and firmly held in place. This is particularly important during the disassembly and reassembly of engine parts, where secure fastening is necessary to prevent damage or misalignment. The screw’s design allows for easy attachment and removal, facilitating efficient and safe handling procedures.

Conclusion

The 5320537 Studded Flange Cap Screw by Cummins is a vital component in the assembly and maintenance of heavy-duty truck engines. Its robust design, high tensile strength, and resistance to vibration make it an ideal choice for securing critical engine components. Proper installation and regular maintenance ensure the longevity and reliability of this part, contributing to the overall performance and efficiency of the engine.

-

Hilgers, Michael. Transmissions and Drivetrain Design. Springer Vieweg, 2022.

↩ -

Reif, Konrad. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩ -

Brown Jr, Andrew. Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles. National Academy of Sciences, 2010.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.