This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

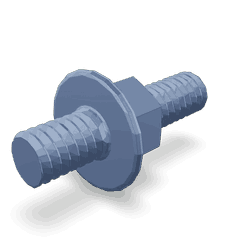

The Studded Flange Cap Screw (Part #5332668) manufactured by Cummins is a specialized fastener designed for heavy-duty truck applications. This component is integral to ensuring secure and reliable connections in various truck systems. Its robust design and high-quality materials make it suitable for demanding environments where durability and performance are paramount 1.

Basic Concepts

Studded flange cap screws are a type of fastener characterized by a threaded shank and a flange at one end. The flange provides additional surface area for torque application, enhancing the screw’s ability to maintain a secure connection. These screws are commonly used in applications requiring high tensile strength and resistance to vibration. They function by threading into a corresponding tapped hole, creating a strong and stable joint that can withstand significant stress and movement 2.

Purpose and Role in Truck Operation

This Cummins part plays a significant role in the operation of heavy-duty trucks by securing critical components and assemblies. It is often used in applications where vibration and dynamic loads are present, such as in the engine compartment, transmission systems, and chassis components. By providing a secure fastening solution, this screw helps maintain the integrity of these systems, ensuring optimal performance and safety 3.

Key Features

The 5332668 Studded Flange Cap Screw boasts several key features that enhance its performance and durability. It is constructed from high-strength materials, typically alloy steel, which offers excellent resistance to wear and corrosion. The screw features a coarse thread design that allows for quick and easy installation while providing a strong grip. The flange at the end of the screw provides additional torque application surface, improving the screw’s ability to resist loosening. Additionally, the screw’s design includes a chamfered end for easy insertion into tapped holes 4.

Benefits

The benefits of using the 5332668 Studded Flange Cap Screw include improved fastening security, enhanced resistance to vibration, and better load distribution. The flange design allows for greater torque application, ensuring a tighter and more secure connection. The screw’s high-strength material and coarse thread design contribute to its durability and reliability in demanding applications. Additionally, the screw’s ability to distribute loads evenly helps prevent stress concentrations, reducing the risk of component failure 1.

Installation Considerations

Proper installation of the 5332668 Studded Flange Cap Screw is crucial to ensure its effectiveness and longevity. It is important to follow torque specifications provided by the manufacturer to achieve the correct clamping force without over-tightening, which could damage the screw or the components being fastened. Alignment of the screw with the tapped hole is also critical to prevent cross-threading and ensure a secure fit. Compatibility with other components, such as washers and gaskets, should be verified to maintain the integrity of the fastening system 2.

Troubleshooting and Maintenance

Common issues with studded flange cap screws include loosening due to vibration, corrosion, and damage from over-tightening. Regular inspection and maintenance can help identify and address these issues promptly. If loosening is detected, re-torque the screw to the specified value. Corrosion can be mitigated by using screws made from corrosion-resistant materials and applying appropriate coatings or treatments. Damaged screws should be replaced to maintain the integrity of the fastening system 3.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation for quality, reliability, and innovation in the automotive and heavy-duty truck industries. The company’s extensive product portfolio includes a wide range of components and systems designed to meet the demanding requirements of modern transportation and power generation applications 4.

Studded Flange Cap Screw 5332668 in Cummins Engines

The Studded Flange Cap Screw 5332668, manufactured by Cummins, is a critical component in various Cummins engine models. This part is designed to secure flanges and other components, ensuring a tight and reliable connection. Below is an overview of how this screw fits into the specified Cummins engines:

ISB3.9 CM2220 B107 and L8.9 CM2670 L134C

The Studded Flange Cap Screw 5332668 is utilized in both the ISB3.9 CM2220 B107 and L8.9 CM2670 L134C engines. In these engines, the screw is essential for securing various flanges, including those used in the exhaust systems and other critical connections. The studded design provides enhanced grip and stability, which is crucial for maintaining the integrity of these connections under high operational stresses 1.

QSB3.9 CM2880 B138

In the QSB3.9 CM2880 B138 engine, the Studded Flange Cap Screw 5332668 plays a pivotal role in securing the flanges in the exhaust system and other critical areas. The robust design of the screw ensures that these connections remain tight and secure, even under the demanding conditions of heavy-duty operations 2.

QSB6.7 M CM2250

For the QSB6.7 M CM2250 engine, the Studded Flange Cap Screw 5332668 is used to secure flanges in several key areas, including the exhaust system and other high-stress connections. The screw’s design provides the necessary stability and durability to maintain these connections under the rigorous demands of the engine’s operation 3.

QSF2.8 CM2880 Series

The QSF2.8 CM2880 series engines, including the F104, F105, F108, and F114 variants, also utilize the Studded Flange Cap Screw 5332668. In these engines, the screw is crucial for securing flanges in the exhaust system and other critical areas. The studded design ensures that these connections remain tight and secure, even under the demanding conditions of heavy-duty operations. The consistency in design across these variants allows for easy interchangeability and maintenance, streamlining the repair and service processes 4.

Role of Part 5332668 Studded Flange Cap Screw in Various Engine Systems

The Part 5332668 Studded Flange Cap Screw is an essential component in several engine systems, ensuring secure and reliable connections across various applications. Its design and functionality make it suitable for integration into multiple systems where robust fastening is required 1.

Module Integration

In modular engine systems, the Studded Flange Cap Screw is utilized to secure modules to the engine frame or other structural components. This ensures that the modules remain firmly in place, even under the dynamic conditions experienced during engine operation. The secure attachment is vital for the proper functioning of the modules, which often house critical components such as sensors, actuators, and control units 2.

Engine Control Systems

Within engine control systems, the Studded Flange Cap Screw plays a significant role in mounting control units and sensors. These units are responsible for monitoring and regulating various engine parameters, such as fuel injection, ignition timing, and emissions. The screw’s studded flange design provides a strong and stable connection, which is essential for the accurate and reliable operation of the control systems 3.

Plumbing Applications

In plumbing applications related to engine systems, the Studded Flange Cap Screw is used to secure fittings and connections in fuel lines, coolant systems, and lubrication circuits. Its robust design ensures that these connections remain leak-free and stable, even under high pressure and temperature conditions. This is particularly important in maintaining the integrity of the fluid systems, which are crucial for engine performance and longevity 4.

Keel Cooler Attachment

For keel coolers, which are used to cool engine oil in marine and industrial applications, the Studded Flange Cap Screw is employed to attach the cooler to the engine or its support structure. The screw’s design allows for a secure and vibration-resistant connection, ensuring that the keel cooler operates efficiently and remains in place during operation. This is important for maintaining optimal oil temperature and engine performance 1.

Shield Mounting

In applications where shields are used to protect sensitive components from heat, debris, or environmental factors, the Studded Flange Cap Screw is used to mount these shields securely. The screw’s flange provides additional surface area for attachment, enhancing the stability and effectiveness of the shield. This is particularly important in high-temperature environments where shields help prevent heat transfer and protect critical engine components 2.

Heat Management Systems

In heat management systems, such as heat exchangers and radiators, the Studded Flange Cap Screw is used to secure components and ensure proper alignment and sealing. Its design allows for a tight and durable connection, which is essential for efficient heat transfer and the overall performance of the cooling system. This ensures that the engine operates within safe temperature ranges, preventing overheating and potential damage 3.

Conclusion

The 5332668 Studded Flange Cap Screw is a critical component in heavy-duty truck and engine systems, providing secure and reliable connections across various applications. Its robust design, high-strength materials, and key features make it suitable for demanding environments where durability and performance are essential. Proper installation, regular maintenance, and understanding its role in different engine systems are crucial for ensuring the longevity and effectiveness of this Cummins part 4.

-

Xin, Q. (2011). Diesel Engine System Design. Woodhead Publishing Limited.

↩ ↩ ↩ ↩ ↩ -

Lakshminarayanan, P. A., & Nayak, N. S. (2011). Critical Component Wear in Heavy Duty Engines. John Wiley & Sons.

↩ ↩ ↩ ↩ ↩ -

Calder, N. (2007). Diesel Engine Care and Repair. The McGraw-Hill Companies.

↩ ↩ ↩ ↩ ↩ -

Limpert, R. (2011). Brake Design and Safety, Third Edition. SAE International.

↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.