This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

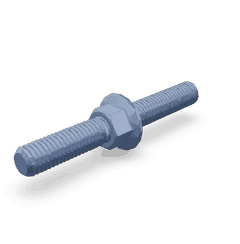

The 5337514 Studded Flange Cap Screw is a specialized fastener produced by Cummins, a well-established manufacturer in the commercial truck industry. This component is designed to meet the demanding requirements of heavy-duty applications, ensuring reliable performance and durability in various truck components.

Basic Concepts

A Studded Flange Cap Screw is a type of fastener that includes a threaded stud and a flanged head. It is commonly used in mechanical systems where secure and robust connections are required. The flange provides additional surface area for torque application, enhancing the screw’s ability to hold components firmly in place. Within an assembly, this type of screw plays a role in joining parts that experience significant stress or vibration, ensuring that the connection remains intact under operational conditions 1.

Purpose and Role in Truck Operation

In the context of commercial trucks, the 5337514 Studded Flange Cap Screw serves a specific purpose by securing critical components that are subject to high stress and dynamic loads. It is often used in applications where the connection must withstand substantial force, such as in the engine compartment or chassis. By providing a secure and stable attachment, this screw contributes to the overall reliability and safety of the truck, facilitating efficient operation and maintenance.

Key Features

The 5337514 Studded Flange Cap Screw boasts several key features that distinguish it from standard cap screws. It is constructed from high-strength materials, typically alloy steel, which offers superior durability and resistance to wear. The design includes a flanged head that enhances torque application and prevents the screw from loosening over time. Additionally, the studded design allows for easy installation and removal, making it a practical choice for maintenance tasks.

Benefits

Using the 5337514 Studded Flange Cap Screw offers several advantages. Its high-strength material composition ensures enhanced durability, making it suitable for high-stress environments commonly found in commercial trucks. The flanged head provides improved torque application, contributing to a more secure connection. Furthermore, the screw’s design promotes reliability in securing critical components, reducing the likelihood of failure and extending the lifespan of the assembly.

Installation Process

Proper installation of the 5337514 Studded Flange Cap Screw involves several steps to ensure a secure and effective fit. Begin by cleaning the mating surfaces to remove any debris or contaminants. Use a torque wrench to install the screw, applying the recommended torque specification to avoid over-tightening, which could damage the threads or the component. Ensure that the flange is seated properly against the surface to maximize the screw’s holding power. Finally, periodically check the connection to confirm that it remains secure during operation.

Troubleshooting and Maintenance

Common issues with the 5337514 Studded Flange Cap Screw may include loosening due to vibration or corrosion. To identify these problems, regularly inspect the screw and the surrounding components for signs of wear or damage. If corrosion is present, clean the affected areas and apply a suitable anti-corrosion treatment. To prevent loosening, ensure that the screw is torqued to the manufacturer’s specifications and consider using a thread locker for added security. Routine maintenance practices, such as periodic inspection and re-torquing, will help prolong the lifespan of the screw and ensure optimal performance.

Cummins Overview

Cummins Inc. is a renowned manufacturer with a rich history in the commercial truck industry. Founded in 1919, the company has built a reputation for producing high-quality engine and power generation equipment. Cummins offers a comprehensive range of products, including engines, filtration systems, and aftermarket parts, all designed to meet the rigorous demands of heavy-duty applications. The company’s commitment to innovation, quality, and customer satisfaction has established it as a trusted source for truck components, making Cummins a preferred choice for fleet operators and maintenance professionals 2.

Integration of Studded Flange Cap Screw Part 5337514 in Cummins Engines

The Studded Flange Cap Screw part 5337514, manufactured by Cummins, is a critical component in the assembly and maintenance of various Cummins engines. This part is designed to provide secure fastening in flange connections, ensuring that the engine’s components remain tightly sealed and properly aligned.

F2.8 CM2620 F135B

In the F2.8 CM2620 F135B engine, the Studded Flange Cap Screw part 5337514 is utilized in several key areas where flange connections are essential. These include the attachment of exhaust manifolds, coolant flanges, and other critical components that require a robust and reliable fastening solution. The studded design of the screw ensures that it can withstand the high pressures and temperatures typical of engine environments.

ISB6.7 G CM2180 B118, ISF2.8 CM2220 F117, ISF2.8 CM2220 F129

The ISB6.7 G CM2180 B118 engine, along with the ISF2.8 CM2220 F117 and ISF2.8 CM2220 F129 engines, also benefit from the use of the Studded Flange Cap Screw part 5337514. These engines share similar design principles and operational requirements, necessitating the use of this screw in various flange connections. The screw’s design ensures that it can maintain the integrity of these connections under the demanding conditions of engine operation.

R2.8 CM2220 R101B

The R2.8 CM2220 R101B engine incorporates the Studded Flange Cap Screw part 5337514 in its construction, particularly in areas where flange connections are critical for the engine’s performance and durability. This includes the attachment of components such as turbochargers, intake manifolds, and other parts that require a secure and reliable fastening method. The studded feature of the screw provides an additional layer of security, ensuring that the connections remain tight and stable over time.

Each of these engines relies on the Studded Flange Cap Screw part 5337514 to maintain the structural integrity and operational efficiency of their flange connections. This part’s design and material properties make it an essential component in the assembly and maintenance of these Cummins engines.

Role of Part 5337514 Studded Flange Cap Screw in Engine Systems

The Part 5337514 Studded Flange Cap Screw is integral to the secure assembly and operation of various engine components. Its primary function is to provide a robust fastening solution that ensures components remain firmly in place under the demanding conditions of engine operation.

Air Intake Connection

In the air intake system, the 5337514 Studded Flange Cap Screw is used to secure the air intake connection to the air intake manifold. This ensures a tight seal, preventing air leaks that could affect engine performance and efficiency. The screw’s studded flange design offers additional stability, crucial for maintaining the integrity of the air intake path.

Air Intake Manifold

When attaching the air intake manifold to the engine block, the 5337514 Studded Flange Cap Screw plays a key role. It ensures that the manifold is securely fastened, which is essential for uniform air distribution to the cylinders. This contributes to optimal combustion and overall engine performance.

Electronic Control Module (ECM) Wiring Harness

The ECM wiring harness requires secure mounting to prevent damage from vibrations and ensure consistent electrical connections. The 5337514 Studded Flange Cap Screw is employed to fasten the harness in place, providing the necessary stability and protection for the sensitive electronic components.

Engine Control Wiring Harness

Similarly, the engine control wiring harness benefits from the secure fastening provided by the 5337514 Studded Flange Cap Screw. This ensures that all electrical connections remain intact, facilitating reliable communication between the engine’s various sensors and the ECM.

Fuel Plumbing

In fuel systems, the 5337514 Studded Flange Cap Screw is used to secure fuel lines and fittings. This is vital for maintaining the integrity of the fuel delivery system, ensuring that fuel is delivered consistently and without leaks, which is essential for engine operation.

Turbocharger

For turbocharged engines, the 5337514 Studded Flange Cap Screw is utilized in securing the turbocharger to the engine. This ensures that the turbocharger remains firmly attached, allowing it to operate efficiently and withstand the high pressures and temperatures generated during operation.

Water Inlet Connection

In cooling systems, the screw is used to secure the water inlet connection to the engine block. This is important for maintaining a sealed cooling system, which is essential for effective heat dissipation and engine temperature regulation.

Overall, the 5337514 Studded Flange Cap Screw is a versatile and reliable fastening solution that enhances the performance and durability of various engine components.

Conclusion

The 5337514 Studded Flange Cap Screw is a critical component in the assembly and maintenance of Cummins engines, providing secure fastening in flange connections and ensuring the structural integrity and operational efficiency of various engine systems. Its high-strength material composition, flanged head design, and studded feature make it an essential part for heavy-duty applications, contributing to the overall reliability and safety of commercial trucks.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.