This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

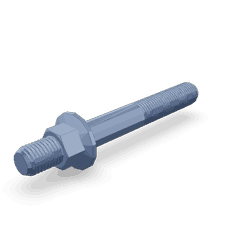

The 5347959 Studded Flange Cap Screw is a specialized fastener produced by Cummins, a well-established manufacturer in the commercial truck industry. This screw is designed for use in various applications within commercial trucks, where it plays a role in securing components and ensuring the integrity of mechanical assemblies.

Basic Concepts of Studded Flange Cap Screws

A studded flange cap screw is a type of fastener that features a threaded shank and a flanged head. The flange provides a larger surface area for distribution of clamping force, which helps in securing components more effectively 1. These screws are commonly used in mechanical assemblies where a high degree of security and resistance to vibration is required. The studded flange design allows for easier installation and removal, as well as providing a visual indication of proper torque application 2.

Purpose of the 5347959 Studded Flange Cap Screw in Truck Operation

In the context of commercial trucks, the 5347959 Studded Flange Cap Screw serves to secure various components across different truck systems. It is particularly useful in applications where components are subject to significant vibration or where a high clamping force is necessary to maintain the integrity of the assembly. This screw is applied in engine components, transmission systems, and other critical areas where reliable fastening is paramount 3.

Key Features

The 5347959 Studded Flange Cap Screw boasts several key features that enhance its performance and durability. It is constructed from high-strength materials, ensuring it can withstand the rigors of commercial truck operation. The screw features a specific threading type that provides optimal engagement with mating components, and its flange design allows for efficient distribution of clamping force. Additionally, the screw may include unique attributes such as corrosion-resistant coatings or specialized threading to further improve its functionality in harsh environments.

Benefits

Utilizing the 5347959 Studded Flange Cap Screw offers several advantages. The design of the screw contributes to improved security of fastened components, reducing the risk of loosening due to vibration. Its material composition and construction provide resistance to corrosion, enhancing the screw’s longevity in demanding operating conditions. Furthermore, the ease of installation and the visual torque indication offered by the flange contribute to efficient maintenance practices.

Installation Guidelines

Proper installation of the 5347959 Studded Flange Cap Screw is vital for ensuring optimal performance. Installation should follow specific torque specifications provided by the manufacturer to achieve the correct clamping force without over-tightening. It is also important to ensure that mating surfaces are clean and free from debris to facilitate a secure fit. Special considerations may include the use of thread lockers or anti-seize compounds, depending on the application and environmental conditions.

Troubleshooting and Maintenance

Common issues with the 5347959 Studded Flange Cap Screw may include loosening over time or corrosion in exposed applications. Regular inspection and maintenance are recommended to address these issues. If loosening is detected, re-torquing the screw to the manufacturer’s specifications can often resolve the issue. In cases of corrosion, cleaning the affected area and applying a corrosion-resistant treatment may be necessary to prolong the screw’s lifespan.

Cummins: Manufacturer Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration systems, and aftermarket parts. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range and focus on reliability make it a preferred choice for components like the 5347959 Studded Flange Cap Screw, ensuring that truck operators can rely on high-performance fastening solutions.

Studded Flange Cap Screw 5347959 in Cummins Engines

The Studded Flange Cap Screw 5347959, manufactured by Cummins, is a critical component in several of their engine models. This part is integral to the assembly and operation of the engines, ensuring secure fastening and stability.

Engines Utilizing the 5347959 Studded Flange Cap Screw

15N CM2380 M104B, D4.0 CM2620 D103B, F3.8 CM2350 F120B, F3.8 CM2350 F128C, F3.8 CM2620 F137B, F4.5 CM2620 F139B

These engines, which include the 15N CM2380 M104B, D4.0 CM2620 D103B, F3.8 CM2350 F120B, F3.8 CM2350 F128C, F3.8 CM2620 F137B, and F4.5 CM2620 F139B, all utilize the 5347959 Studded Flange Cap Screw. This part is essential for maintaining the structural integrity of the engine’s flange connections, ensuring that components are securely fastened and aligned.

ISF3.8 CM2220 AN, ISF3.8 CM2350 F109, ISF4.5 CM2220 F123

The ISF3.8 CM2220 AN, ISF3.8 CM2350 F109, and ISF4.5 CM2220 F123 engines also incorporate the 5347959 Studded Flange Cap Screw. This screw is vital for the proper assembly and operation of these engines, providing the necessary strength and durability to withstand the operational stresses.

QSF3.8 CM2880 F112

The QSF3.8 CM2880 F112 engine is another model that relies on the 5347959 Studded Flange Cap Screw. This component ensures that the flange connections are tightly secured, contributing to the overall reliability and performance of the engine.

X12N CMMDG1 X143B

Lastly, the X12N CMMDG1 X143B engine uses the 5347959 Studded Flange Cap Screw. This part is crucial for maintaining the integrity of the flange connections in this engine, ensuring that all components are properly fastened and aligned.

Each of these engines benefits from the use of the 5347959 Studded Flange Cap Screw, which plays a pivotal role in the assembly and operational efficiency of the engine.

Role of Part 5347959 Studded Flange Cap Screw in Engine Systems

The Part 5347959 Studded Flange Cap Screw is instrumental in securing various components within engine systems, ensuring stability and proper function.

Manifold Integration

In the context of the manifold, the 5347959 Studded Flange Cap Screw is used to fasten the manifold to the engine block or other structural components. This secure attachment is essential for maintaining the integrity of the manifold, which distributes the air-fuel mixture to the cylinders. Proper fastening prevents leaks and ensures that the manifold remains in the correct position, contributing to efficient engine performance.

Air Intake System

Within the air intake system, the 5347959 Studded Flange Cap Screw plays a significant role in attaching the air intake components, such as the air filter housing and intake manifold. This secure connection is vital for maintaining a sealed system, which is necessary for optimal airflow into the engine. Efficient airflow is critical for combustion efficiency and overall engine performance. The screw ensures that all components remain firmly in place, reducing the risk of vibrations or disconnections that could impair engine function.

By providing a robust and reliable fastening solution, the 5347959 Studded Flange Cap Screw contributes to the durability and efficiency of these engine components.

Conclusion

The 5347959 Studded Flange Cap Screw is a critical component in the commercial truck industry, particularly in Cummins engines. Its design and features ensure secure fastening, resistance to vibration, and longevity in harsh environments. Proper installation and maintenance are essential for optimal performance, highlighting the importance of this Cummins part in ensuring the reliability and efficiency of truck operations.

-

Reif, K. (2014). Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg.

↩ -

Reif, K. (2014). Diesel Engine Management Systems and Components. Springer.

↩ -

Denton, T., & Pells, H. (2022). Automotive Technician Training Theory. Routledge.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.