5365025

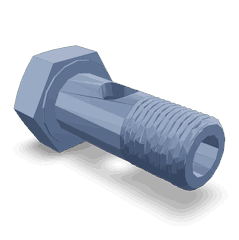

Banjo Connector Screw

Cummins®

AVAILABLE

4 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 5365025 Banjo Connector Screw, manufactured by Cummins, is a specialized component used in the fluid systems of commercial trucks. Cummins is a well-established name in the automotive industry, known for its high-quality and reliable components. This part is integral to the efficient operation of fluid systems, ensuring proper fluid transfer and system integrity.

Basic Concepts and Functionality

A banjo connector screw is a type of fitting used in fluid systems to connect hoses or pipes to various components. It consists of a bolt with a hollow, typically cylindrical body that allows fluid to pass through. The screw is secured with a nut, and a gasket or O-ring ensures a tight seal, preventing leaks. In commercial trucks, banjo connector screws are commonly used in hydraulic and fuel systems to facilitate the transfer of fluids under pressure. The design allows for easy connection and disconnection, which is crucial for maintenance and system adjustments 1.

Purpose of the 5365025 Banjo Connector Screw

The 5365025 Banjo Connector Screw plays a specific role in the operation of commercial trucks by ensuring the reliable transfer of fluids within hydraulic and fuel systems. Its function is to provide a secure connection point that allows fluids to flow between components while maintaining system pressure and preventing leaks. This contributes to the overall efficiency and reliability of the truck’s systems, ensuring that critical functions such as braking, steering, and fuel delivery operate smoothly 2.

Key Features

The 5365025 Banjo Connector Screw is designed with several key features that enhance its performance and durability. It is typically made from high-strength materials such as stainless steel, which provides corrosion resistance and longevity. The design includes precise threading and a robust body to withstand high pressures. Additionally, the screw often features integrated gaskets or O-rings to ensure a leak-proof seal. These characteristics make it well-suited for the demanding environments found in commercial trucking.

Benefits

Using the 5365025 Banjo Connector Screw offers several benefits. Its high-quality construction ensures improved system integrity, reducing the risk of leaks and system failures. The design allows for ease of installation, which is particularly important during maintenance procedures. Additionally, the robust material and precise engineering contribute to longevity, reducing the need for frequent replacements. These factors collectively enhance the operational efficiency of commercial trucks 3.

Installation and Usage

Proper installation of the 5365025 Banjo Connector Screw is crucial for optimal performance. It should be torqued to the manufacturer’s recommended settings to ensure a secure fit without over-tightening, which could damage the gasket or threads. Specific instructions may include the use of thread lubricant to facilitate installation and prevent galling. The screw is used in various truck systems, including hydraulic lines, fuel systems, and brake systems, where reliable fluid transfer is essential.

Troubleshooting and Maintenance

Common issues with the 5365025 Banjo Connector Screw may include leaks or connection failures. Troubleshooting should begin with a visual inspection for signs of wear, corrosion, or damage to the gasket or O-ring. Regular maintenance involves checking the torque settings and ensuring that all connections are secure. Inspection intervals should be in accordance with the manufacturer’s guidelines, and any signs of wear or failure should prompt immediate replacement to prevent system downtime.

Cummins: Manufacturer Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions systems. With a history spanning over a century, Cummins has built a reputation for quality, innovation, and reliability in the commercial truck industry. The company is committed to advancing technology and providing solutions that meet the evolving needs of its customers, ensuring that their components, like the 5365025 Banjo Connector Screw, deliver high performance and durability.

Cummins Banjo Connector Screw 5365025 in Engine Applications

The Cummins Banjo Connector Screw 5365025 is a critical component in various engine systems, ensuring secure and leak-proof connections for hydraulic or fuel lines. This part is integral to maintaining the integrity of the engine’s fluid systems, which is essential for optimal performance and reliability.

B3.3 Engine Group

In the B3.3 engine series, the Banjo Connector Screw 5365025 is utilized to secure hoses that transport critical fluids such as fuel or hydraulic oil. Its design allows for a tight seal, preventing any leaks that could compromise engine efficiency or safety. The screw’s robust construction ensures it can withstand the operational stresses and environmental conditions typical in engine environments.

The application of this screw in the B3.3 engine series highlights its versatility and importance in maintaining the engine’s fluid systems. The screw’s role in securing connections is vital for the overall functionality and longevity of the engine, making it a key component in the maintenance and repair processes.

Role of Part 5365025 Banjo Connector Screw in Engine Systems

In the realm of engine systems, the part 5365025 Banjo Connector Screw plays a significant role in ensuring the integrity and efficiency of fuel delivery systems. This component is integral to the secure connection between various fuel system components, facilitating a reliable and leak-free transfer of fuel.

Integration with Fuel Filter Plumbing

The Banjo Connector Screw is often utilized in the fuel filter plumbing system. It connects the fuel lines to the fuel filter, ensuring that fuel flows smoothly from the tank to the engine. This connection is vital for maintaining the cleanliness of the fuel, as the filter removes impurities that could otherwise damage engine components. The secure fit provided by the Banjo Connector Screw prevents fuel leaks, which are not only a safety hazard but also lead to inefficient fuel consumption.

Connection to Fuel Inlet Fitting

Another key application of the Banjo Connector Screw is in the connection to the fuel inlet fitting of the engine. This fitting is the point where fuel enters the engine’s fuel system. A reliable connection here is essential for the consistent delivery of fuel to the engine’s combustion chambers. The Banjo Connector Screw ensures that this connection is tight and secure, preventing any fuel loss or air intake that could disrupt the fuel-to-air ratio, affecting engine performance.

Ensuring System Integrity

By providing a secure and leak-proof connection in both the fuel filter plumbing and the fuel inlet fitting, the Banjo Connector Screw contributes to the overall integrity of the engine’s fuel system. It ensures that fuel is delivered efficiently and safely to the engine, supporting optimal performance and longevity of the engine components.

Conclusion

The 5365025 Banjo Connector Screw is a vital component in the fluid systems of commercial trucks and engines. Its robust design, high-quality materials, and precise engineering ensure reliable fluid transfer, system integrity, and longevity. Proper installation, regular maintenance, and timely replacement are essential to maximize the benefits of this Cummins part, contributing to the overall efficiency and reliability of commercial truck operations.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.