This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

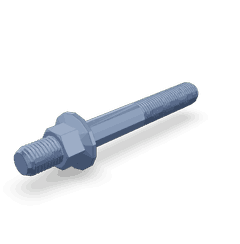

The 5399718 Studded Flange Cap Screw is a specialized fastener produced by Cummins, a reputable manufacturer known for its high-quality automotive components. This particular cap screw is designed for use in commercial truck applications, where it plays a significant role in ensuring the integrity and functionality of various truck systems.

Basic Concepts

A Studded Flange Cap Screw is a type of fastener that features a threaded stud on one end and a flange on the other. This design allows it to be secured with a nut on the threaded end while the flange provides a bearing surface that distributes load and prevents the screw from pulling through the material. In mechanical applications, these screws are used to join components securely, often in environments where vibration and stress are common 1.

Purpose and Role in Truck Operation

In the context of commercial trucks, the 5399718 Studded Flange Cap Screw serves a specific purpose by securing critical components and assemblies. It is often used in applications where a high level of durability and resistance to loosening is required. By providing a stable and secure connection, this cap screw contributes to the overall operation and maintenance of the vehicle, ensuring that components remain firmly in place under various driving conditions 2.

Key Features

The 5399718 Studded Flange Cap Screw is distinguished by several key features. It is made from high-strength materials, ensuring durability in heavy-duty applications. The design includes a studded end for secure fastening with a nut and a flange that offers additional stability and load distribution. These characteristics make it suitable for demanding environments where standard cap screws might fail 3.

Benefits

Using the 5399718 Studded Flange Cap Screw offers several advantages. Its high-strength material composition enhances durability, allowing it to withstand the rigors of commercial truck operation. The design elements, such as the flange and stud, contribute to improved performance by providing a secure and stable connection. Additionally, the reliability of this cap screw reduces the need for frequent replacements, offering long-term value in maintenance scenarios 4.

Installation Process

Proper installation of the 5399718 Studded Flange Cap Screw involves several steps. First, ensure that the mating surfaces are clean and free of debris. Next, align the screw with the designated hole and begin threading it in by hand to avoid cross-threading. Once started, use an appropriate torque wrench to tighten the screw to the manufacturer’s specified torque settings. This ensures that the screw is secure without being overtightened, which could damage the threads or the flange 5.

Troubleshooting and Maintenance

Common issues with the 5399718 Studded Flange Cap Screw may include loosening due to vibration or corrosion. Regular inspection and tightening can prevent these problems. If corrosion is detected, cleaning the affected area and applying a suitable anti-seize compound can help. Maintenance tips include checking torque settings periodically and ensuring that nuts and mating surfaces remain clean and free of contaminants 6.

Common Applications

The 5399718 Studded Flange Cap Screw is typically used in various components and systems within commercial trucks. Examples include securing engine mounts, transmission housings, and other critical assemblies where vibration and stress are present. Its robust design makes it ideal for these applications, ensuring that components remain securely fastened 7.

Safety Considerations

When working with the 5399718 Studded Flange Cap Screw, it is important to follow safety guidelines. Ensure that all tools and equipment are in good condition and that proper personal protective equipment is worn. Handle the screw carefully to avoid injury from sharp edges, and follow torque specifications to prevent damage to the screw or the components it secures 8.

About Cummins

Cummins is a reputable manufacturer with a strong presence in the automotive industry. Known for producing high-quality components, Cummins is committed to innovation and excellence. Their products, including the 5399718 Studded Flange Cap Screw, are designed to meet the demanding requirements of commercial truck applications, ensuring reliability and performance 9.

Cummins Engine Compatibility with Studded Flange Cap Screw Part 5399718

The Studded Flange Cap Screw part number 5399718, manufactured by Cummins, is a critical component in the assembly of various Cummins engines. This part is designed to secure flanges and other components, ensuring a tight and reliable connection. Its application is widespread across multiple engine models, providing a robust solution for maintaining structural integrity and operational efficiency.

B3.3 Engine

In the B3.3 engine, the Studded Flange Cap Screw part 5399718 is utilized in several key areas. It is often employed to fasten components that require a secure and durable connection, such as exhaust manifolds, intake manifolds, and other critical flanges. The studded design of the screw ensures that it can withstand the high stresses and vibrations typical in engine environments, contributing to the engine’s overall reliability and performance.

QSB3.3 and CM2150 Engines

For the QSB3.3 and CM2150 engines, the Studded Flange Cap Screw part 5399718 serves similar functions. These engines, known for their robust design and versatility, benefit from the enhanced security provided by this screw. It is commonly used in the attachment of various engine components, including but not limited to, turbocharger housings, coolant manifolds, and other critical flanges. The studded feature of the screw ensures that it can maintain a tight grip even under the demanding conditions of engine operation, thereby contributing to the longevity and efficiency of the engine.

The use of part 5399718 across these engines underscores its importance in maintaining the structural integrity and operational efficiency of Cummins engines. Its design and application are tailored to meet the specific needs of each engine model, ensuring that it performs optimally in its intended role.

Role of Part 5399718 Studded Flange Cap Screw in Engine Systems

In the context of engine systems, the Part 5399718 Studded Flange Cap Screw is instrumental in ensuring the secure attachment and stability of various components.

Alternator Mounting

When it comes to alternator mounting, the Studded Flange Cap Screw plays a significant role. It is used to fasten the alternator to the engine block or bracket, ensuring that the alternator remains firmly in place. This secure attachment is essential for the alternator to function correctly, as any movement can lead to inefficient operation or even damage. The screw’s design allows for a tight and durable connection, which is vital for the alternator’s performance and longevity.

General Mounting Applications

Beyond the alternator, the Studded Flange Cap Screw is widely used in various mounting applications throughout the engine system. It is employed to secure components such as brackets, sensors, and other auxiliary parts to the engine block or chassis. This versatility ensures that different parts remain stable and correctly positioned, contributing to the overall efficiency and reliability of the engine.

Importance in Engine Stability

The secure attachment provided by the Studded Flange Cap Screw is fundamental to the stability of the engine system. By ensuring that components are firmly mounted, it helps prevent vibrations and movement that could otherwise lead to wear, misalignment, or failure of engine parts. This stability is particularly important in high-performance engines where precision and reliability are paramount.

Conclusion

In summary, the Part 5399718 Studded Flange Cap Screw is a key component in maintaining the integrity and performance of engine systems through its reliable mounting capabilities. Its robust design and high-strength material composition make it suitable for demanding environments, ensuring that components remain securely fastened and contributing to the overall reliability and efficiency of commercial truck engines.

-

Automotive Fuels Reference Book, Paul Richards and Jim Barker, SAE International, 2023.

↩ -

Entire Vehicle: Second Edition, Michael Hilgers, Springer Nature, 2023.

↩ -

The Evolution of Automotive Engineering: A Handbook, Gijs Mom, SAE International, 2023.

↩ -

Automobile Wheel Alignment and Wheel Balancing, R Mananathan, SAE International, 2022.

↩ -

Fault Code Troubleshooting Manual, Cummins, Bulletin Number 4358563, 2023.

↩ -

Automotive Fuels Reference Book, Paul Richards and Jim Barker, SAE International, 2023.

↩ -

Entire Vehicle: Second Edition, Michael Hilgers, Springer Nature, 2023.

↩ -

The Evolution of Automotive Engineering: A Handbook, Gijs Mom, SAE International, 2023.

↩ -

Fault Code Troubleshooting Manual, Cummins, Bulletin Number 4358563, 2023.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.