This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Socket Head Cap Screw 5419137 is a specialized fastener produced by Cummins, a leading manufacturer in the commercial truck industry. This screw is designed for use in various applications within commercial trucks, contributing to the secure assembly of components and ensuring reliable performance under demanding conditions.

Basic Concepts of Socket Head Cap Screws

Socket Head Cap Screws are a type of fastener characterized by a hexagonal socket in the head, allowing for efficient and secure tightening using a hex key. These screws are commonly used in mechanical assemblies where high strength and resistance to loosening are required. They function by providing a strong, permanent connection between parts, distributing load evenly, and resisting rotational forces 1.

Purpose of Socket Head Cap Screw 5419137 in Truck Operations

This part plays a specific role in the operation and maintenance of commercial trucks. It is utilized in applications where secure fastening is crucial, such as in engine components, transmission systems, and chassis assemblies. Its design ensures that parts remain firmly attached, even under the vibrations and stresses encountered during truck operation.

Key Features

The Socket Head Cap Screw 5419137 is distinguished by several key features that enhance its functionality. It is typically made from high-strength materials, such as alloy steel, to provide durability and resistance to wear. The screw’s design includes a countersunk head for flush installation and a precise thread pitch for optimal engagement. Additionally, it may feature a corrosion-resistant coating to protect against environmental factors 2.

Benefits

Using this Cummins part offers several advantages. Its high-strength material ensures long-lasting performance, while the hexagonal socket allows for easy and precise installation. The screw’s resistance to loosening helps maintain secure connections over time, reducing the need for frequent maintenance. Furthermore, its design contributes to efficient load distribution, enhancing the overall reliability of truck components.

Installation and Usage

Proper installation of the Socket Head Cap Screw 5419137 is crucial for ensuring its effectiveness. It should be installed using the appropriate hex key to achieve the specified torque, which ensures a secure connection without over-tightening. Best practices include cleaning the mating surfaces before installation and periodically checking the screw’s tightness during routine maintenance to prevent loosening 3.

Troubleshooting and Maintenance

Common issues with Socket Head Cap Screws include loosening due to vibrations and corrosion from exposure to moisture or chemicals. Troubleshooting involves checking for proper torque and inspecting for signs of wear or corrosion. Maintenance tips include regular inspection of screws in critical applications, re-tightening as necessary, and applying a thread locker to prevent loosening. In cases of severe corrosion, replacement of the screw may be required to ensure continued reliability.

Safety Considerations

When working with Socket Head Cap Screws, it is important to observe safety practices to prevent injury and ensure proper installation. This includes using the correct tools, such as a hex key of the appropriate size, and wearing personal protective equipment (PPE) like gloves and safety glasses. Handling screws with care and following manufacturer guidelines for torque specifications are also critical to safe and effective use.

Cummins: A Brief Overview

Cummins is a renowned manufacturer with a significant presence in the commercial truck industry. Founded in 1919, the company has a long history of innovation and quality in engine and power generation technologies. Cummins is known for its commitment to producing reliable and efficient components that meet the demanding requirements of commercial truck applications. Their products, including the Socket Head Cap Screw 5419137, are designed with precision and durability in mind, contributing to the overall performance and longevity of trucks.

Socket Head Cap Screw (Part 5419137) in Cummins Engines

The Socket Head Cap Screw, identified by the part number 5419137, is a critical component in the assembly and maintenance of various Cummins engines. This part is integral to the structural integrity and operational efficiency of the engines, ensuring that various components are securely fastened.

QSK95 and CM2350 Engines

In the QSK95 and CM2350 engines, the Socket Head Cap Screw 5419137 is utilized in several key areas. These engines, known for their robust performance and reliability, require precise fastening to maintain their operational standards. The screw is often used in the assembly of engine blocks, cylinder heads, and other critical assemblies where high strength and durability are paramount. Its design allows for secure fastening, reducing the risk of loosening under operational stresses.

K113 Engine

The K113 engine also benefits from the use of the Socket Head Cap Screw 5419137. This engine, part of the Cummins lineup, is designed for heavy-duty applications, and the screw’s role is crucial in maintaining the integrity of its components. The screw is used in various mounting and fastening applications, ensuring that parts are held firmly in place, which is essential for the engine’s performance and longevity.

Common Applications

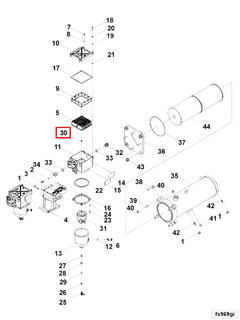

Across these engines, the Socket Head Cap Screw 5419137 is employed in several common applications:

- Engine Block Assembly: Ensuring the engine block remains securely fastened.

- Cylinder Head Attachment: Providing a reliable connection between the cylinder head and the engine block.

- Mounting Brackets: Securing various engine components to their respective mounts.

- Accessory Drive Systems: Ensuring that components such as pulleys and tensioners are firmly attached.

The use of this screw in these engines highlights its importance in maintaining the structural and operational integrity of the engines. Its design and material properties ensure that it can withstand the rigors of engine operation, providing a reliable fastening solution.

Role of Part 5419137 Socket Head Cap Screw in Engine Systems

The part 5419137 Socket Head Cap Screw is integral in securing various components within engine systems, ensuring stability and reliability. In the context of accessories, this screw is often used to mount and secure additional components such as sensors, gauges, or other auxiliary devices that enhance engine performance and monitoring. Its design allows for a snug fit, minimizing vibrations and ensuring that these accessories remain firmly in place under varying operational conditions.

Within the fuel system, the Socket Head Cap Screw plays a significant role in attaching and securing the fuel filter. The fuel filter is a vital component that removes impurities from the fuel before it reaches the engine, ensuring optimal combustion and prolonging the engine’s lifespan. The screw ensures that the fuel filter is held securely in its housing, preventing any leaks or misalignments that could disrupt the fuel flow and affect engine performance.

Moreover, the Socket Head Cap Screw is also utilized in various other fuel system components, such as fuel lines and connectors, to maintain the integrity of the system. Its application in these areas ensures that all connections are tight and secure, contributing to the overall efficiency and safety of the fuel delivery process.

Conclusion

The Socket Head Cap Screw 5419137 by Cummins is a critical component in the assembly and maintenance of commercial trucks and Cummins engines. Its high-strength material, precise design, and resistance to loosening make it an essential fastener for ensuring the secure attachment of various components. Proper installation, regular maintenance, and adherence to safety practices are vital for maximizing the performance and longevity of this part in demanding truck and engine applications.

-

Dixon, John. Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning, 2010.

↩ -

Mom, Gijs. The Evolution of Automotive Engineering: A Handbook. SAE International, 2023.

↩ -

Osgood, Libby, Gayla Cameron, and Emma Christensen. Engineering Mechanics: Statics. Creative Commons, 2024.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.