This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

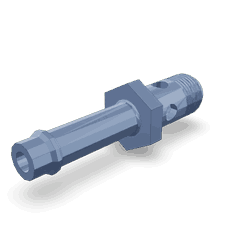

The 5486092 Banjo Connector Screw, manufactured by Cummins, is a component used in the maintenance and operation of commercial trucks. This part is integral to the fluid systems within these vehicles, ensuring the efficient transfer of fluids such as hydraulic or fuel. Cummins, a well-established name in the commercial truck industry, produces this connector screw with a focus on reliability and performance, making it a valuable component for truck maintenance professionals 1.

Basic Concepts of Banjo Connector Screws

A Banjo Connector Screw is a type of fitting used in fluid systems to connect hoses or pipes to various components. It typically consists of a banjo bolt, a sealing washer, and a nut. The banjo bolt has a hollow, cylindrical body with an internal passage for fluid flow. When tightened, the nut compresses the sealing washer against the banjo bolt and the component it is connecting to, creating a secure and leak-proof seal. In the context of a truck’s hydraulic or fuel system, the Banjo Connector Screw facilitates the transfer of fluids under pressure, ensuring the system operates efficiently 2.

Purpose of the 5486092 Banjo Connector Screw

The 5486092 Banjo Connector Screw serves a specific role in the operation of a truck by connecting hoses or pipes to various components within the truck’s hydraulic or fuel system. Its design allows for the secure transfer of fluids, ensuring that the system functions correctly. This connector screw is particularly important in maintaining the integrity of the fluid pathways, preventing leaks, and ensuring that the system operates under the correct pressure conditions 3.

Key Features

The 5486092 is designed with several features that make it suitable for its intended use. It is constructed from high-quality materials that can withstand the pressures and temperatures encountered in truck fluid systems. The thread type is selected to ensure a secure fit, while the sealing mechanisms are designed to prevent leaks. These features contribute to the connector screw’s reliability and durability in demanding applications 4.

Benefits

Using the 5486092 offers several advantages. Its reliable design ensures consistent performance, reducing the likelihood of system failures. The ease of installation is another benefit, as the connector screw is designed to be quickly and securely fitted into place. Additionally, the maintenance benefits include straightforward inspection and replacement procedures, contributing to the overall efficiency of truck maintenance operations.

Installation Process

Installing the 5486092 involves several steps to ensure a secure and leak-proof connection. Begin by cleaning the connection points to remove any debris or old sealant. Apply a compatible sealant to the threads of the banjo bolt if required. Insert the banjo bolt into the component and align the hose or pipe. Place the sealing washer over the banjo bolt, followed by the nut. Tighten the nut to the manufacturer’s specified torque, ensuring the connection is secure without over-tightening, which could damage the sealing washer or the component.

Troubleshooting Common Issues

Common issues with Banjo Connector Screws include leaks and connection failures. To troubleshoot these problems, first, ensure that the connector screw is correctly installed and tightened to the specified torque. Check for any signs of damage to the sealing washer or the banjo bolt. If leaks persist, consider replacing the sealing washer or the entire connector screw. Regular inspections can help identify potential issues before they lead to system failures.

Maintenance Tips

To ensure the longevity and proper function of the 5486092, regular maintenance practices are recommended. Inspect the connector screw and its connections during routine maintenance checks for signs of wear, corrosion, or leaks. Cleaning the connection points and applying a compatible sealant as needed can help maintain a secure seal. Following these maintenance tips can contribute to the efficient operation of the truck’s fluid systems.

Compatibility and Applications

The 5486092 is designed for use in various truck models and systems, with specific applications within Cummins-powered vehicles. It is important to consult the manufacturer’s guidelines for compatibility and any specific requirements or considerations for use in different truck models or systems.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history of innovation and quality, Cummins has established a strong reputation in the commercial truck industry. The company’s commitment to excellence is reflected in its product range, which includes components like the 5486092, designed to meet the demanding requirements of commercial truck applications.

Cummins Banjo Connector Screw 5486092 Compatibility

The Cummins Banjo Connector Screw part number 5486092 is designed to fit seamlessly with several engine models, ensuring a secure and leak-proof connection for hydraulic or fuel lines. This part is crucial for maintaining the integrity of the engine’s fluid systems.

X12 CM2350

In the X12 CM2350 engine, the 5486092 is used to secure the banjo fitting to the engine’s hydraulic or fuel lines. This ensures that the connection remains tight and reliable under various operating conditions, preventing leaks and maintaining system efficiency.

X119B

Similarly, in the X119B engine, the 5486092 plays a vital role in securing the banjo fitting. This engine relies on precise fluid connections to function optimally, and the screw ensures that the connections are both secure and leak-proof.

Grouping of Engines

The X12 CM2350 and X119B engines share common design principles and fluid management systems, which is why the 5486092 is compatible with both. This compatibility allows for easier maintenance and part replacement across different engine models, providing a streamlined approach to engine upkeep.

Conclusion

The 5486092 Banjo Connector Screw is a critical component in the maintenance and operation of commercial trucks, particularly those powered by Cummins engines. Its design and features ensure reliable and efficient fluid transfer within the truck’s hydraulic or fuel systems. Regular maintenance and proper installation are key to maximizing the benefits of this part, contributing to the overall performance and longevity of the vehicle’s fluid systems.

-

Parikyan Ed, T. (2022). Advances in Engine and Powertrain Research and Technology. Springer Nature.

↩ -

Hilgers, M. (2023). Alternative Powertrains and Extensions to the Conventional Powertrain. Springer Nature.

↩ -

Garrett, T.K., Newton, K., & Steeds, W. (2001). The Motor Vehicle. Reed Educational and Professional Publishing Ltd.

↩ -

Carroll, D.R. (2020). Energy Efficiency of Vehicles. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.