This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

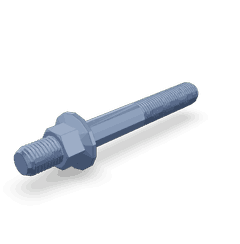

The Studded Flange Cap Screw, identified by part number 5486506, is a component manufactured by Cummins, a prominent entity in the automotive industry. This screw is integral to the assembly and operation of heavy-duty trucks. Its design and functionality are tailored to meet the demanding requirements of truck mechanics, ensuring reliable performance under various operational conditions.

Basic Concepts of Studded Flange Cap Screws

A Studded Flange Cap Screw is a type of fastener characterized by a threaded shank and a flanged head. The flange provides a larger surface area for distribution of clamping force, which enhances the screw’s ability to secure components firmly. These screws are utilized across multiple industries for their robustness and efficiency in joining metal parts 1.

Purpose of the 5486506 Studded Flange Cap Screw in Truck Operation

This part plays a role in the assembly and functionality of truck components by providing a secure connection between parts. It is designed to withstand the dynamic loads and vibrations typical in heavy-duty truck operations, ensuring that critical components remain firmly attached 2.

Key Features of the 5486506 Studded Flange Cap Screw

The 5486506 is constructed from high-strength materials, typically alloy steel, which contributes to its durability and resistance to wear. It features a coarse thread that allows for quick assembly and disassembly, and its flanged head design distributes clamping force more effectively than standard cap screws. Additionally, the screw may include features such as a corrosion-resistant coating to enhance its performance in harsh environments 3.

Benefits of Using the 5486506 Studded Flange Cap Screw

Incorporating this Cummins part into truck assemblies offers several advantages. It provides improved load distribution due to its flanged head, which reduces the risk of component failure under stress. The screw’s design also enhances security by minimizing the likelihood of vibration-induced loosening. Furthermore, its material composition and construction contribute to resistance against corrosion and mechanical wear.

Installation Guidelines

Proper installation of the 5486506 is vital for optimal performance. It should be installed with the correct torque specification to ensure a secure fit without over-tightening, which could damage the screw or the components being joined. Best practices include using a torque wrench for precise application of force and ensuring that mating surfaces are clean and free of debris to facilitate a strong connection.

Troubleshooting Common Issues

Common issues with Studded Flange Cap Screws include corrosion, stripping, and loosening. Corrosion can be mitigated by selecting screws with appropriate coatings for the operational environment. Stripping may occur if the screw is over-tightened or if it is not compatible with the material of the components being joined. Loosening can often be addressed by re-torquing the screw or by using lock washers or thread-locking compounds.

Maintenance Tips

Regular maintenance of the 5486506 involves periodic inspection for signs of wear, corrosion, or loosening. Cleaning the screw and its mating surfaces can prevent buildup that may affect performance. Replacement should be considered if there is significant wear or if the screw no longer provides a secure connection.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins serves the automotive industry, particularly in the heavy-duty truck sector, by providing reliable and high-performance components. The company’s product range includes a variety of parts designed to meet the rigorous demands of truck operations.

Integration of Studded Flange Cap Screw in Cummins Engines

The Studded Flange Cap Screw, part number 5486506, manufactured by Cummins, is a critical component in the assembly and maintenance of several Cummins engines. This part is integral to ensuring the secure fastening of flanges, which are essential for sealing and connecting various engine components.

Application in X12 CM2350 and X119B Engines

In the X12 CM2350 engine, the Studded Flange Cap Screw is utilized in multiple areas where flanges need to be fastened securely. These include the connection of the exhaust manifold to the engine block, ensuring a tight seal to prevent exhaust leaks. Additionally, it is used in the fastening of the intake manifold, which is crucial for maintaining the integrity of the air intake system.

Similarly, in the X119B engine, the Studded Flange Cap Screw plays a vital role in the assembly of the exhaust manifold and the intake manifold. Its use in these areas ensures that the flanges are held firmly in place, which is essential for the engine’s performance and longevity.

Importance of the Studded Flange Cap Screw

The use of studded flange cap screws in these engines is not merely a matter of convenience but a necessity for the engine’s operational safety and efficiency. The studs provide a robust and reliable means of securing flanges, which is critical in environments where engines are subjected to high temperatures and pressures. The design of the studded flange cap screw allows for easy installation and removal, which is beneficial during maintenance and repair operations.

Compatibility and Specifications

The Studded Flange Cap Screw, part number 5486506, is designed to meet the stringent specifications required for use in Cummins engines. This includes the material composition, which is typically high-strength steel, ensuring durability and resistance to the harsh conditions within the engine. The threading and length of the screw are also tailored to fit the specific requirements of the flanges in the X12 CM2350 and X119B engines.

Maintenance and Replacement

Regular inspection and maintenance of the Studded Flange Cap Screw are essential to ensure that it remains in optimal condition. Over time, the screws can become worn or damaged, which can compromise the integrity of the flange connections. Therefore, it is recommended to replace the screws as part of routine maintenance or when any signs of wear are detected.

Role of Part 5486506 Studded Flange Cap Screw in Engine Systems

The Part 5486506 is instrumental in ensuring the secure and efficient operation of various engine components. In the context of an engine arrangement, this screw plays a significant role in maintaining the structural integrity of the engine block and its associated components. It is often used to fasten critical parts such as cylinder heads, valve covers, and other engine covers, ensuring that these components remain firmly in place under the high stresses and vibrations experienced during engine operation.

In accessory support systems, the Studded Flange Cap Screw is employed to secure accessories like alternators, water pumps, and air conditioning compressors to the engine. This ensures that these accessories are held in the correct position and alignment, which is essential for their efficient operation and longevity. The studded flange design of the screw provides additional surface area for a more robust connection, reducing the risk of loosening over time.

Furthermore, the use of this screw in both the engine arrangement and accessory support highlights its versatility and reliability in various applications within the engine system. Its design allows for easy installation and removal, facilitating maintenance and repair processes. The secure fastening provided by the Studded Flange Cap Screw contributes to the overall stability and performance of the engine, ensuring that all components work in harmony to deliver optimal engine function.

Conclusion

The Studded Flange Cap Screw, part number 5486506, is a vital component in the assembly and maintenance of heavy-duty trucks and Cummins engines. Its robust design, high-strength material, and flanged head contribute to secure fastening, improved load distribution, and resistance to corrosion and wear. Proper installation, regular maintenance, and timely replacement are essential to ensure the optimal performance and longevity of this critical component.

-

Dixon, John. Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning, 2010.

↩ -

Awari, G.K., Kumbhar, V.S., and Tirpude, R.B. Automotive Systems Principles and Practice. CRC Press, 2011.

↩ -

Miedema, S. A., and Lu, Z. The Dynamic Behavior of a Diesel Engine. Published by Drir S. A. Miedema, 2010.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.