This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

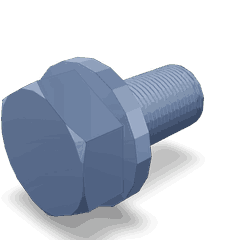

The Cummins 5527452 Captive Washer Cap Screw is a specialized fastener designed for use in commercial trucks. Cummins, a well-established name in the automotive industry, produces a range of components that enhance the performance and reliability of heavy-duty vehicles. This Cummins part plays a significant role in the assembly and maintenance of truck engines and other mechanical systems.

Basic Concepts

A Captive Washer Cap Screw is a type of fastener that includes an integrated washer, which is held in place by a protrusion or step on the screw’s shaft. This design ensures that the washer remains attached to the screw, reducing the risk of loss during installation and providing a more consistent and secure fastening solution. In mechanical assemblies, these screws are used to join components together, providing both structural integrity and electrical insulation where necessary 1.

Purpose and Role in Truck Operation

This part serves a specific purpose in the operation of a truck by securing various components within the engine and other mechanical systems. Its role is to maintain the structural integrity of these assemblies, ensuring that parts remain firmly in place under the dynamic conditions experienced by commercial trucks. This fastener helps to distribute loads evenly across joined surfaces, reducing the risk of component failure and enhancing the overall reliability of the truck 2.

Key Features

The 5527452 boasts several key features that enhance its performance. Its design includes an integrated washer, which simplifies the installation process and ensures consistent torque application. The screw is made from high-quality materials, offering excellent resistance to corrosion and wear. Additionally, its unique attributes, such as a hexagonal socket head for easy tightening and a zinc-plated finish for added durability, make it a reliable choice for demanding applications.

Benefits

Using the 5527452 provides several advantages. Its design contributes to improved reliability by ensuring that the washer remains in place, which is crucial for maintaining the integrity of the fastening. The ease of installation reduces assembly time and labor costs, while the screw’s durability and resistance to environmental factors contribute to maintenance efficiency. These benefits make the 5527452 an invaluable component in the maintenance and operation of commercial trucks.

Installation Process

Proper installation of the 5527452 is vital for ensuring optimal performance and longevity. The process involves selecting the appropriate screw size for the application, cleaning the mating surfaces to remove any debris or contaminants, and using a torque wrench to tighten the screw to the manufacturer’s specified torque settings. Careful attention to these steps will help to achieve a secure and lasting fastening solution.

Troubleshooting and Maintenance

Common issues with the 5527452 may include loosening over time due to vibration or corrosion. Regular inspections and maintenance can help to identify and address these issues before they lead to component failure. Troubleshooting tips include checking for proper torque application, ensuring that mating surfaces are clean and free of contaminants, and replacing screws that show signs of wear or corrosion. These practices will help to prolong the service life of the fastener and maintain the integrity of the truck’s mechanical systems.

Safety Considerations

When handling and installing the 5527452, it is important to observe several safety guidelines and precautions. These include wearing appropriate personal protective equipment, such as gloves and safety glasses, to protect against injury. Additionally, ensuring that the work area is clean and free of hazards will help to prevent accidents. Following the manufacturer’s torque specifications and using the correct tools for installation will also contribute to safe and effective use of the fastener.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions technologies. With a history spanning over a century, Cummins has established a strong reputation for quality, reliability, and customer satisfaction in the commercial truck industry. The company’s extensive product range and commitment to innovation make it a trusted partner for truck manufacturers and operators worldwide.

Captive Washer Cap Screw (Part 5527452) Compatibility with Cummins Engines

The Captive Washer Cap Screw, part number 5527452, manufactured by Cummins, is a critical component used in various Cummins engine models. This part is designed to secure and stabilize different engine parts, ensuring the integrity and performance of the engine. Below is a detailed description of its compatibility with specific Cummins engine models:

ISC Series Engines

- ISC CM2150

- ISC CM554

- ISC CM850

The Captive Washer Cap Screw is utilized in the ISC series engines to secure various components, ensuring that parts remain tightly fastened and aligned. This is crucial for maintaining engine stability and performance.

ISL Series Engines

- ISL CM2150

- ISL CM554

- ISL G CM2180

- ISL9 CM2150 SN

- ISL9 CM2250

In the ISL series engines, the part 5527452 is employed to fasten and secure multiple engine components. Its design ensures that the engine parts are held firmly in place, contributing to the overall reliability and efficiency of the engine.

QSC and QSL Series Engines

- QSC8.3 CM554

- QSC8.3 CM850 (CM2850)

- QSC9 CM2250 / QSL9 CM2250

- QSL8.9 CM2150 L141

- QSL9 CM2250

- QSL9 CM554

- QSL9 CM850 (CM2850)

The Captive Washer Cap Screw is also integral to the QSC and QSL series engines. It is used to secure various components within these engines, ensuring that all parts are tightly fastened and properly aligned. This is essential for maintaining the structural integrity and performance of these engines.

C Series Engines

- C GAS PLUS CM556

- C8.3 G

In the C series engines, the part 5527452 is used to fasten and stabilize key components. Its design ensures that the engine parts are held securely, contributing to the overall efficiency and reliability of the engine.

By using the Captive Washer Cap Screw in these various engine models, Cummins ensures that the engines maintain their structural integrity and operational efficiency. This part plays a crucial role in securing and stabilizing different engine components, making it an essential element in the overall design and performance of Cummins engines.

Role of Part 5527452 Captive Washer Cap Screw in Engine Systems

In the context of engine systems, the Part 5527452 Captive Washer Cap Screw is integral to the assembly and securement of various components. This screw is particularly significant in the Flywheel Housing where it ensures that the housing is tightly secured, preventing any potential misalignment or movement during engine operation.

When it comes to the Flywheel Top Level Assembly Housing, the captive washer cap screw plays a role in maintaining the structural integrity of the assembly. It helps in evenly distributing the load and stress across the housing, which is essential for the smooth functioning of the flywheel.

In the broader Housing components of the engine, this screw is used to fasten different parts together, ensuring that they remain in place under the dynamic conditions of engine operation. Its design allows for easy installation and removal, which is beneficial during maintenance or repair procedures.

For the Flywheel Repto system, the captive washer cap screw is utilized to secure the repto mechanism within the flywheel housing. This ensures that the repto system operates efficiently without any undue stress or movement that could affect its performance.

In the Kit assemblies, which often include a variety of components packaged together for specific engine modifications or repairs, the captive washer cap screw is a common fastening element. It ensures that all parts within the kit are securely attached, facilitating easier installation and reducing the risk of component failure.

Lastly, in the Repto Upfit applications, where additional components are added to the engine for enhanced performance or functionality, the captive washer cap screw is used to integrate these upfits seamlessly into the existing engine structure. This screw ensures that the upfit components are securely fastened, contributing to the overall reliability and performance of the modified engine system.

Conclusion

The Cummins 5527452 Captive Washer Cap Screw is a vital component in the maintenance and operation of commercial trucks. Its design, featuring an integrated washer and high-quality materials, ensures reliable and secure fastening in various engine systems. Proper installation, regular maintenance, and adherence to safety guidelines are essential for maximizing the performance and longevity of this fastener. As a critical part in Cummins engines, the 5527452 contributes significantly to the structural integrity and efficiency of these engines, making it an indispensable element in the automotive industry.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.