3918002

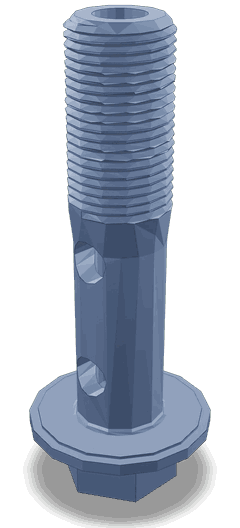

Banjo Connector Screw

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3918002 Banjo Connector Screw, manufactured by Cummins, is a specialized component designed for use in heavy-duty truck systems. This part is integral to the fluid systems of trucks, ensuring secure and efficient connections. Cummins, a well-established name in the automotive and heavy-duty truck industry, produces this component with a focus on quality and reliability.

Basic Concepts of Banjo Connector Screws

A Banjo Connector Screw is a type of fitting used in fluid systems to connect hoses or pipes to various components. It typically consists of a bolt with a hollow body, a sealing washer, and a banjo fitting. The banjo fitting is a short, tubular component with a flat surface that allows for the attachment of hoses or pipes. When tightened, the Banjo Connector Screw compresses the sealing washer against the flat surface of the banjo fitting, creating a secure seal that prevents fluid leaks 1.

Purpose of the 3918002 Banjo Connector Screw

The 3918002 is specifically designed to play a role in the operation of heavy-duty trucks. It is commonly used in brake systems, fuel systems, and hydraulic systems. In these applications, it ensures that fluid connections remain secure and leak-free, which is vital for the safe and efficient operation of the truck 2.

Key Features

The 3918002 is constructed from high-quality materials, typically including stainless steel for the screw and durable synthetic materials for the sealing washer. It features a specific thread type that ensures a tight and secure fit. The design includes a sealing mechanism that provides excellent resistance to fluid leaks and corrosion. Unique design elements may include reinforced banjo fittings for added durability and specialized washers for enhanced sealing performance 3.

Benefits

Using the 3918002 offers several advantages. Its design contributes to improved sealing, which helps prevent fluid leaks that could compromise system performance. The materials used provide resistance to corrosion, extending the component’s lifespan. The screw is designed for ease of installation, allowing for quick and secure connections. Additionally, its long-term reliability makes it a preferred choice over alternative connector types in many applications.

Installation Process

Proper installation of the 3918002 involves several steps. First, ensure that the banjo fitting is correctly aligned with the hose or pipe. Next, place the sealing washer over the flat surface of the banjo fitting. Thread the screw into the fitting, ensuring it is hand-tightened initially to avoid cross-threading. Finally, use a torque wrench to tighten the screw to the manufacturer’s specified torque setting. This ensures a secure connection without over-tightening, which could damage the fitting or washer.

Troubleshooting Common Issues

Common issues with Banjo Connector Screws include leaks, corrosion, and improper sealing. To address leaks, check the sealing washer for damage and replace it if necessary. Ensure the screw is tightened to the correct torque specification. Corrosion can be mitigated by using components made from corrosion-resistant materials and regularly inspecting the connections. Improper sealing may require re-evaluating the alignment of the banjo fitting and the condition of the sealing washer.

Maintenance Tips

Regular maintenance of the 3918002 is important for ensuring longevity and optimal performance. Inspect the connections at regular intervals for signs of wear, corrosion, or leaks. Clean the fittings and screws as part of routine maintenance to remove any buildup that could affect performance. If any component shows signs of wear or damage, consider replacement to maintain system integrity.

Cummins Overview

Cummins Inc. is a leading manufacturer in the automotive and heavy-duty truck industry, known for its commitment to quality and innovation. Founded in 1919, Cummins has a long history of producing reliable and high-performance components. The company’s product range includes engines, filtration systems, and aftermarket parts, all designed to meet the demanding requirements of heavy-duty applications. Cummins’ dedication to excellence is evident in its manufacturing processes and the durability of its products.

Cummins Engine Compatibility with Part 3918002

The Banjo Connector Screw, part number 3918002, manufactured by Cummins, is a critical component used in various engine models. This part is essential for securing hoses and lines in the engine’s fuel, coolant, and other fluid systems, ensuring a tight and leak-proof connection.

4B3.9, 6B5.9, 6C8.3, B5.9 GAS PLUS CM556

The Banjo Connector Screw is used in these engines to secure hoses in the fuel and coolant systems. It ensures that the connections remain tight and leak-proof, which is crucial for maintaining engine performance and preventing fluid loss.

ISB CM850, ISB5.9 CM2880 B110, ISB5.9 CM2880 B140, ISB5.9G CM2180

In the ISB series engines, the 3918002 is used to secure various hoses, including those in the fuel, coolant, and oil systems. Its application in these engines ensures that all connections are secure and reliable, contributing to the engine’s overall efficiency and longevity.

ISC CM554, ISC CM850, ISL CM554, ISL9 CM2150 SN, ISM CM876, ISX CM871, ISX12 CM2350 X102, ISX12/ISX11.9 CM2250, ISX15 CM2250

For the ISC, ISL, ISM, and ISX series engines, the Banjo Connector Screw is used in multiple systems, including fuel, coolant, and oil lines. Its application in these engines is critical for maintaining the integrity of the fluid systems, ensuring that there are no leaks and that the engine operates smoothly.

L8.9 L121, QSB5.9 CM2880 B115, QSC8.3 CM554, QSL9 CM554

In the L8.9 L121, QSB5.9 CM2880 B115, QSC8.3 CM554, and QSL9 CM554 engines, the 3918002 is used to secure hoses in the fuel and coolant systems. Its role in these engines is to provide a reliable and leak-proof connection, which is essential for maintaining the engine’s performance and preventing any fluid-related issues.

Role of Part 3918002 Banjo Connector Screw in Various Engine Systems

The Banjo Connector Screw, identified by part number 3918002, is an essential component in numerous engine systems, facilitating the secure connection of various fluid and air lines. Its application spans across multiple subsystems, ensuring efficient operation and reliability.

Fuel Systems

In fuel systems, the Banjo Connector Screw is utilized in the fuel plumbing to connect the fuel pump to the fuel injection pump. This connection is vital for maintaining the integrity of the fuel line, preventing leaks, and ensuring consistent fuel delivery to the engine. Additionally, it is employed in the fuel pump lubrication system, where it connects the fuel pump lubricating plumbing to the fuel pump, guaranteeing proper lubrication and prolonging the lifespan of the fuel pump components.

Air Systems

For air systems, the Banjo Connector Screw plays a significant role in the air compressor setup. It is used in the air compressor mounting to connect the compressor to the air coupling, ensuring a secure and leak-free connection. This is particularly important in systems where the compressor is part of a turbocharger setup, where air delivery efficiency directly impacts engine performance.

Exhaust and Recirculation Systems

In exhaust recirculation systems, the Banjo Connector Screw is employed to connect the exhaust recirculation water plumbing to the recirculation supply. This connection is essential for managing exhaust gases and improving engine efficiency. Similarly, in fuel pump lubrication systems, it connects the plumbing to the latchout oil press, ensuring that the lubrication system operates smoothly and effectively.

Additional Applications

Beyond the primary systems, the Banjo Connector Screw is also used in the front gear train accessory and fuel control module connections. In these applications, it ensures that all fluid and air lines are securely connected, contributing to the overall reliability and performance of the engine.

Conclusion

The 3918002 Banjo Connector Screw is a versatile component that enhances the functionality and efficiency of various engine systems through secure and reliable connections. Its role in fuel, air, exhaust, and recirculation systems, as well as additional applications, underscores its importance in maintaining the performance and longevity of heavy-duty engines.

-

Reif, Konrad Ed. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩ -

Dixon, John. Modern Diesel Technology: Heating, Ventilation, Air Conditioning, Refrigeration, 2nd Edition. Cengage Learning, 2014.

↩ -

Taghavifar, Hamid and Mardani, Aref. Offroad Vehicle Dynamics Analysis Modelling and Optimization. Springer, 2017.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.