3957770

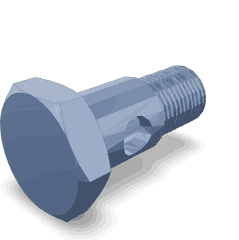

Banjo Connector Screw

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3957770 Banjo Connector Screw, manufactured by Cummins, is a critical component in commercial truck operations. Cummins, a well-established name in the industry, produces this part to ensure reliable and efficient fluid system connections in trucks. The Banjo Connector Screw is integral to maintaining the functionality of hydraulic and fuel systems in commercial vehicles.

Basic Concepts and Functionality

A Banjo Connector Screw is a type of fitting used in fluid systems to connect hoses or pipes to various components. It typically consists of a bolt with an integrated fitting that allows for the secure attachment of hoses. In the context of a truck’s hydraulic or fuel system, this part facilitates the transfer of fluids under pressure, ensuring that systems operate smoothly and efficiently 1.

Role in Truck Operation

The 3957770 Banjo Connector Screw plays a specific role in the operation of a commercial truck by connecting hoses or pipes to critical components within the hydraulic or fuel system. This connection is vital for the proper distribution of fluids, which in turn supports the functioning of brakes, transmissions, and other systems reliant on hydraulic or fuel pressure 2.

Key Features

The design and construction of the 3957770 Banjo Connector Screw include several features that enhance its performance and durability. It is typically made from high-quality materials resistant to corrosion and capable of withstanding high pressures. The thread type is designed to provide a secure fit, and the overall construction ensures a reliable seal, preventing leaks and maintaining system integrity 3.

Benefits

Using the 3957770 Banjo Connector Screw offers several advantages. Its design allows for improved sealing, which is crucial for maintaining system pressure and efficiency. The screw is also designed for ease of installation, reducing downtime during maintenance procedures. Additionally, its resistance to corrosion and high pressures ensures longevity and reliable performance in demanding commercial truck environments.

Installation Process

Proper installation of the 3957770 Banjo Connector Screw involves several steps to ensure a secure and leak-free connection. It is important to follow torque specifications provided by the manufacturer to achieve the correct tightness without over-tightening, which could damage the fitting or the connected components. Precautions such as cleaning the mating surfaces and inspecting the screw for any damage before installation are also recommended.

Troubleshooting Common Issues

Common problems associated with Banjo Connector Screws include leaks and connection failures. These issues can often be traced back to improper installation, damage to the fitting, or corrosion. Troubleshooting steps may involve re-torquing the connection, replacing damaged components, or cleaning and inspecting the fitting and mating surfaces to ensure a proper seal.

Maintenance Tips

To ensure the longevity and reliable performance of the 3957770 Banjo Connector Screw, regular maintenance practices are recommended. This includes periodic inspection for signs of wear or corrosion, ensuring that connections remain tight and secure, and replacing the screw if any damage is detected. Adhering to these maintenance tips can help prevent unexpected failures and extend the service life of the component.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-performance components. The company’s product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding requirements of commercial vehicle operations.

Cummins Engine Part 3957770: Banjo Connector Screw

The Banjo Connector Screw, part number 3957770, is a critical component in the fuel and fluid systems of various Cummins engines. This part is designed to secure the banjo fitting to the engine’s fuel lines, ensuring a leak-proof connection. Below is a detailed description of how this part fits with the listed Cummins engines:

B Series Engines

- B4.5 CM2350 B129B

- B4.5 CM2350 B104

- B3.9 CM2220 B107

The Banjo Connector Screw is integral to the B series engines, providing a secure connection for the fuel lines that feed into the injection pump. This screw ensures that the banjo fitting remains tightly sealed, preventing any fuel leaks that could compromise engine performance.

D Series Engines

- D4.0 CM2620 D103B

In the D series engines, the Banjo Connector Screw is used to secure the banjo fitting on the fuel lines that connect to the injection pump. This ensures a reliable and leak-proof connection, which is crucial for maintaining the engine’s performance and efficiency.

F Series Engines

- F3.8 CM2350 F120B

- F3.8 CM2350 F128C

- F3.8 CM2620 F137B

- F4.5 CM2620 F139B

The F series engines utilize the Banjo Connector Screw to secure the banjo fittings on their fuel lines. This part is essential for maintaining the integrity of the fuel system, ensuring that the engine receives a consistent and reliable fuel supply.

ISB Series Engines

- ISB CM850

- ISB3.9 CM2220 B107

- ISB4.5 CM2350 B104

- ISB5.9 CM2880 B127

- ISB6.7 G CM2180 B118

In the ISB series engines, the Banjo Connector Screw is used to secure the banjo fittings on the fuel lines that connect to the injection pump. This ensures that the engine’s fuel system remains sealed and leak-free, which is vital for optimal engine performance.

ISBE Series Engines

- ISBE CM800

The ISBE series engine uses the Banjo Connector Screw to secure the banjo fittings on its fuel lines. This part is crucial for maintaining the integrity of the fuel system and ensuring that the engine operates efficiently.

ISF Series Engines

- ISF3.8 CM2220 AN

- ISF3.8 CM2350 F109

In the ISF series engines, the Banjo Connector Screw is used to secure the banjo fittings on the fuel lines. This ensures that the engine’s fuel system remains sealed and leak-free, which is essential for maintaining engine performance.

ISZ Series Engines

- ISZ13 CM2150 Z105

The ISZ series engine utilizes the Banjo Connector Screw to secure the banjo fittings on its fuel lines. This part is critical for maintaining the integrity of the fuel system and ensuring that the engine operates efficiently.

QSB Series Engines

- QSB3.9 CM2880 B138

- QSB4.5 CM850(CM2850)

- QSB5.9 CM2880 B139

- QSB6.7 CM850(CM2850)

- QSB7 CM2880 B117

The QSB series engines use the Banjo Connector Screw to secure the banjo fittings on their fuel lines. This ensures that the engine’s fuel system remains sealed and leak-free, which is crucial for maintaining engine performance.

QSF Series Engines

- QSF3.8 CM2350 F107

- QSF3.8 CM2880 F112

In the QSF series engines, the Banjo Connector Screw is used to secure the banjo fittings on the fuel lines. This ensures that the engine’s fuel system remains sealed and leak-free, which is essential for maintaining engine performance.

QSZ Series Engines

- QSZ13 CM2150 Z101

- QSZ13 CM2150 Z102

The QSZ series engines utilize the Banjo Connector Screw to secure the banjo fittings on their fuel lines. This part is critical for maintaining the integrity of the fuel system and ensuring that the engine operates efficiently.

Role of Part 3957770 Banjo Connector Screw in Engine Systems

The 3957770 Banjo Connector Screw is integral to the efficient operation of various engine systems. In the fuel system, it ensures secure connections between the fuel inlet and the fuel lines, maintaining the integrity of the fuel delivery system. This part is often found in the hardware kit for fuel system accessories, providing a reliable seal that prevents fuel leaks.

In turbocharger plumbing, the Banjo Connector Screw plays a significant role by connecting the turbocharger to the engine’s air intake system. It ensures that the pressurized air from the turbocharger is delivered efficiently to the engine’s combustion chambers, enhancing performance.

For the engine coolant system, this screw fitting is used in the plumbing to connect the coolant lines, ensuring that the coolant circulates properly through the engine block and radiator. This helps in maintaining optimal engine temperature and preventing overheating.

In exhaust recirculation systems, the Banjo Connector Screw is employed to connect the plumbing that reroutes a portion of the exhaust gases back into the intake manifold. This reduces nitrogen oxide emissions and improves fuel efficiency.

Additionally, in the fuel drain plumbing, this component ensures that any excess fuel is safely drained from the system, preventing potential hazards and maintaining system cleanliness.

The Banjo Connector Screw is also utilized in vent systems to connect various venting components, ensuring that pressure is properly managed within the engine compartment.

Overall, the 3957770 Banjo Connector Screw is a versatile and essential component in maintaining the functionality and safety of various engine systems.

Conclusion

The 3957770 Banjo Connector Screw is a vital component in the operation of commercial trucks and various Cummins engines. Its role in ensuring secure and leak-free connections in hydraulic and fuel systems cannot be overstated. Proper installation, regular maintenance, and understanding its applications across different engine systems are crucial for maximizing its performance and longevity.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.