This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

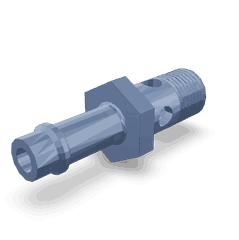

The 3970267 Banjo Connector Screw, manufactured by Cummins, is a specialized component designed for use in commercial trucks. This part is integral to the truck’s hydraulic and fuel systems, ensuring the secure connection of hoses and pipes. Its role is to facilitate the transfer of fluids while maintaining system integrity and performance.

Function and Operation

The 3970267 operates by providing a secure and leak-proof connection between hoses and pipes within the truck’s hydraulic or fuel systems. It features a unique design that allows for the efficient transfer of fluids under pressure. The screw’s threads ensure a tight seal, which is crucial for maintaining system pressure and preventing leaks. This component plays a role in the overall efficiency and reliability of the truck’s systems by ensuring that fluid connections remain intact and functional under various operating conditions 1.

Key Features

The 3970267 is constructed from high-quality materials, typically including steel or stainless steel, which offer excellent durability and resistance to corrosion. Its design incorporates precise threading and a robust body to withstand high pressure and mechanical stress. Additionally, the screw may feature a banjo bolt and washer assembly, which enhances its sealing capabilities and ensures a secure connection. These features contribute to the screw’s reliability and longevity in demanding commercial truck applications 2.

Benefits

The 3970267 provides several advantages, including improved system reliability due to its secure and leak-proof connections. Its design allows for ease of installation, reducing downtime during maintenance procedures. Additionally, the screw’s durable construction and resistance to corrosion contribute to lower maintenance requirements and extended service life, making it a cost-effective solution for commercial truck operators 3.

Installation Process

Proper installation of the 3970267 involves several steps to ensure a secure and effective fit. Begin by cleaning the connection points to remove any debris or old sealant. Apply a compatible thread sealant to the screw threads to enhance the seal. Using the appropriate torque wrench, tighten the screw to the manufacturer’s specified torque settings to avoid over-tightening, which could damage the connection. Finally, inspect the connection for leaks and ensure that all components are properly seated.

Maintenance and Troubleshooting

To maintain the 3970267 and ensure its longevity, regular inspections should be conducted to check for signs of wear, corrosion, or leaks. If any issues are detected, the screw should be replaced or repaired as necessary. Common problems may include leaks due to worn seals or improper installation. Troubleshooting steps include re-torquing the screw to the correct settings, replacing damaged seals, or inspecting the connection points for debris.

Safety Considerations

When working with the 3970267, it is important to observe several safety practices. Ensure that the truck’s engine is off and the system is depressurized before beginning any work. Use the appropriate personal protective equipment, such as gloves and safety glasses, to protect against potential hazards. Follow the manufacturer’s guidelines for torque settings and installation procedures to prevent damage to the component or the system. Additionally, be aware of the potential for fluid leaks, which can pose a slip hazard or environmental risk.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation for quality and innovation in the commercial truck industry. The company’s extensive product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding requirements of commercial applications. Cummins parts, like the 3970267, are trusted by professionals for their reliability, durability, and performance, contributing to the overall efficiency and safety of commercial truck operations.

Role of 3970267 in Various Engine Systems

Plumbing Systems

In plumbing systems, the 3970267 is integral for secure connections between pipes and fittings. It ensures a leak-free seal, maintaining the integrity of fluid transfer within the system. This component is often used in high-pressure applications where reliability and durability are paramount.

Radiator Systems

Within radiator systems, the 3970267 plays a significant role in connecting hoses to the radiator and other cooling system components. It facilitates the efficient circulation of coolant, which is essential for maintaining optimal engine temperature. The secure fitting provided by this screw helps prevent coolant leaks, ensuring the cooling system operates effectively.

Turbocharger Systems

In turbocharger systems, the 3970267 is used to connect oil lines that supply lubrication to the turbocharger. This connection is vital for the turbocharger’s performance and longevity. The screw ensures a consistent oil flow, which is necessary for reducing friction and wear on moving parts within the turbocharger.

Conclusion

Overall, the 3970267 is a versatile component that enhances the functionality and reliability of various engine systems by providing secure and leak-proof connections. Its use in commercial trucks ensures that fluid systems remain efficient, reliable, and safe.

-

Lakshminarayanan, P. A., & Kumar, A. (2020). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature.

↩ -

Hilgers, M. (2023). Electrical Systems and Mechatronics, Second Edition. Springer Vieweg.

↩ -

Bonneau, D., Fatu, A., & Souchet, D. (2014). Internal Combustion Engine Bearings Lubrication in Hydrodynamic Bearings. Wiley-ISTE.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.