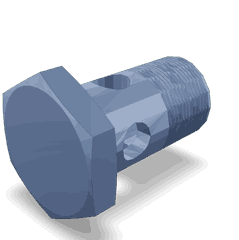

4940181

Banjo Connector Screw

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 4940181 Banjo Connector Screw, manufactured by Cummins, is a specialized component designed for use in commercial trucks. Cummins, a well-established name in the commercial truck industry, produces a wide range of parts and systems that enhance the performance and reliability of heavy-duty vehicles. This Cummins part is integral to the hydraulic and fuel systems of these trucks, ensuring efficient fluid transfer and system integrity.

Basic Concepts of Banjo Connector Screw

A Banjo Connector Screw is a type of fitting used in hydraulic and fuel systems to connect hoses to various components. It typically consists of a banjo bolt, a sealing washer, and a nut. The banjo bolt features a hollow, cylindrical body with a threaded end and a flat surface that houses the sealing washer. When tightened, the nut compresses the washer against the flat surface, creating a seal that prevents fluid leakage. This fitting allows for the secure connection of hoses to fittings, facilitating the transfer of fluids under pressure.

Role of the 4940181 Banjo Connector Screw in Truck Operation

The 4940181 Banjo Connector Screw plays a significant role in the operation of commercial trucks by connecting hoses to fittings within the hydraulic and fuel systems. Its primary function is to manage the flow of fluids, such as hydraulic oil or fuel, ensuring that these critical systems operate efficiently. By providing a secure and leak-proof connection, the banjo connector screw helps maintain system pressure and performance, which is vital for the truck’s overall functionality.

Key Features

The 4940181 Banjo Connector Screw is designed with several key features that enhance its performance and durability. It is constructed from high-quality materials, typically steel or stainless steel, which offer excellent resistance to corrosion and wear. The thread type is standardized to ensure compatibility with various fittings and hoses commonly used in commercial trucks. Additionally, the design includes precise machining to ensure a tight and reliable seal, minimizing the risk of leaks. The inclusion of a sealing washer further enhances the connector’s ability to maintain fluid integrity under pressure.

Benefits

The 4940181 Banjo Connector Screw offers several benefits that contribute to the reliable operation of commercial trucks. One of the primary advantages is improved fluid sealing, which prevents leaks and maintains system pressure. The ease of installation is another significant benefit, as the standardized thread type allows for quick and straightforward connection and disconnection of hoses. Additionally, the materials used in its construction provide resistance to corrosion and wear, ensuring longevity and consistent performance even in demanding operating conditions.

Troubleshooting and Maintenance

Common issues that may arise with Banjo Connector Screws include leaks or connection failures. These problems can often be traced to improper installation, damaged sealing washers, or corrosion. Regular inspection and maintenance are recommended to ensure the longevity and reliable performance of these fittings. This includes checking for signs of wear or corrosion, ensuring that the sealing washer is in good condition, and verifying that the connections are tight and secure. Promptly addressing any issues can prevent more significant problems and maintain the efficiency of the hydraulic and fuel systems.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration systems, and related technologies. Founded in 1919, Cummins has built a reputation for innovation, quality, and reliability in the commercial truck industry. The company’s extensive product range includes engines, powertrains, and aftermarket parts, all designed to enhance the performance and durability of heavy-duty vehicles. Cummins’ commitment to excellence and customer satisfaction has made it a trusted name among commercial truck operators and manufacturers.

Cummins Engine Compatibility with Part 4940181

The Banjo Connector Screw, part number 4940181, manufactured by Cummins, is a crucial component in various engine systems. This part is designed to secure hoses and lines, ensuring a tight and leak-proof connection. Here is a detailed look at its compatibility across different Cummins engines:

ISB Series Engines

- ISB CM2150

- ISB6.7 CM2250

- ISB6.7 CM2350 B101

The ISB series engines, including the ISB CM2150, ISB6.7 CM2250, and ISB6.7 CM2350 B101, utilize the Banjo Connector Screw to maintain the integrity of hydraulic and fuel lines. This part is essential for ensuring that connections remain secure under the high pressures and vibrations typical of these engines.

ISX Series Engines

- ISX12 CM2350 X102

- ISX12/ISX11.9 CM2250

- ISX15 CM2250

- ISX15 CM2250 SN

- ISX15 CM2350 X101

The ISX series engines, such as the ISX12 CM2350 X102, ISX12/ISX11.9 CM2250, ISX15 CM2250, ISX15 CM2250 SN, and ISX15 CM2350 X101, also benefit from the use of the Banjo Connector Screw. These engines are known for their robust performance, and the screw ensures that all fluid lines are properly secured, preventing leaks and maintaining system efficiency.

QSK Series Engines

- QSK95 CM2350 K111

- QSK95 CM2350 K113

The QSK series engines, including the QSK95 CM2350 K111 and QSK95 CM2350 K113, incorporate the Banjo Connector Screw to maintain the integrity of their fluid lines. This part is vital for ensuring that the engine’s hydraulic and fuel systems operate without leaks, contributing to the overall reliability of these engines.

QSX Series Engines

- QSX11.9 CM2250 ECF

- QSX15 CM2250

- QSX15 CM2250 ECF

- QSX15 CM2350 X105

The QSX series engines, such as the QSX11.9 CM2250 ECF, QSX15 CM2250, QSX15 CM2250 ECF, and QSX15 CM2350 X105, also use the Banjo Connector Screw. This part ensures that all connections in the engine’s fluid systems are secure, which is crucial for the high-performance demands of these engines.

ISZ and QSZ Series Engines

- ISZ13 CM2150 Z105

- QSZ13 CM2150 Z101

- QSZ13 CM2150 Z102

The ISZ and QSZ series engines, including the ISZ13 CM2150 Z105, QSZ13 CM2150 Z101, and QSZ13 CM2150 Z102, utilize the Banjo Connector Screw to secure their fluid lines. This ensures that the engines operate efficiently and reliably, with no leaks in the hydraulic or fuel systems.

X Series Engines

- X11 CM2670 X126B

- X12 CM2350 X119B

- X12 CM2670 X121B

The X series engines, such as the X11 CM2670 X126B, X12 CM2350 X119B, and X12 CM2670 X121B, also incorporate the Banjo Connector Screw. This part is essential for maintaining the integrity of the engine’s fluid lines, ensuring that the engine operates smoothly and efficiently.

Role of Part 4940181 Banjo Connector Screw in Engine Systems

The 4940181 Banjo Connector Screw is an essential component in various engine systems, facilitating the secure connection of hoses and pipes to ensure efficient fluid transfer. Its applications span across multiple subsystems, each playing a distinct role in the overall performance and reliability of the engine.

Fuel System Integration

In the fuel system, the 4940181 Banjo Connector Screw is utilized to connect the fuel lines to the fuel filter and the fuel injectors. This ensures a consistent and uninterrupted flow of fuel from the tank to the combustion chambers, which is vital for maintaining engine performance and efficiency. The secure fitting provided by the banjo connector screw prevents fuel leaks, which could otherwise lead to dangerous situations and inefficient engine operation.

Turbocharger Coolant Plumbing

For engines equipped with turbochargers, the 4940181 Banjo Connector Screw is employed in the turbocharger coolant plumbing system. It connects the turbocharger coolant supply tube and the turbocharger coolant drain tube to the cylinder head and the turbocharger gasket kit. This connection is imperative for managing the temperature of the turbocharger, thereby enhancing its longevity and performance. Effective coolant flow regulated by the banjo connector screw helps in dissipating heat, preventing overheating, and ensuring the turbocharger operates within optimal temperature ranges.

Cylinder Head and Rocker Arm Assembly

In the cylinder head and rocker arm assembly, the 4940181 Banjo Connector Screw is used to connect various plumbing lines that supply and drain fluids. This includes connections to the camshaft and the connecting rod and piston components. Proper fluid management in these areas is essential for lubrication and cooling, directly impacting the durability and efficiency of the engine. The banjo connector screw ensures that these connections are tight and secure, minimizing the risk of leaks and maintaining consistent fluid pressure.

Turbocharger and Lever Mechanisms

The banjo connector screw also plays a role in the turbocharger and lever mechanisms by securing the connections in the turbocharger plumbing and the turbocharger coolant supply tube. These connections are critical for the efficient operation of the turbocharger, which relies on precise fluid dynamics to function correctly. The secure fittings provided by the banjo connector screw ensure that the turbocharger receives the necessary coolant and lubrication, contributing to its overall performance and reliability.

Drain and Supply Tubes

Additionally, the 4940181 Banjo Connector Screw is used in the fuel drain and various drain tubes throughout the engine. These include the turbocharger coolant drain tube and the turbocharger coolant drain tube. Effective drainage is essential for removing contaminants and excess fluids, which can otherwise accumulate and cause damage to engine components. The banjo connector screw ensures that these drain tubes are properly connected, facilitating efficient fluid removal and maintaining the cleanliness of the engine system.

Primer and Performance Enhancement

In the context of engine priming and performance enhancement, the 4940181 Banjo Connector Screw is used to connect the primer system to the fuel system. This ensures that the engine can be primed effectively, allowing for easier starting and improved performance. The secure connections provided by the banjo connector screw are vital for maintaining the integrity of the priming system, ensuring that it functions as intended.

Conclusion

The 4940181 Banjo Connector Screw is a versatile and indispensable component in various engine systems, contributing to the efficient and reliable operation of the engine by ensuring secure and leak-free connections across multiple subsystems. Its role in maintaining system integrity, preventing leaks, and ensuring efficient fluid transfer is crucial for the performance and durability of commercial trucks.

References

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.