C6204131610

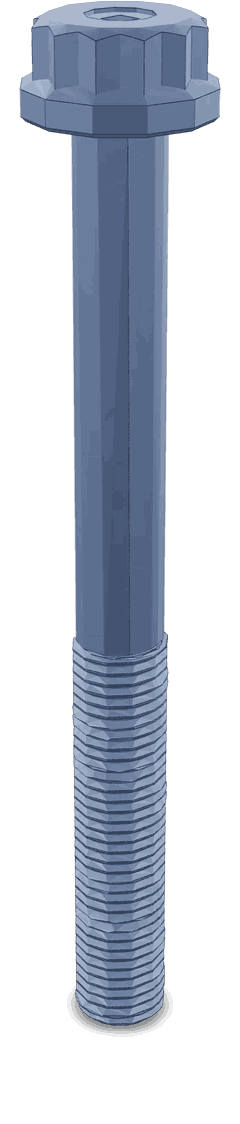

Hexagon Flange Head Cap Screw

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The C6204131610 Hexagon Flange Head Cap Screw is a specialized fastener widely used in commercial truck applications. Manufactured by Cummins, a renowned company in diesel engine manufacturing, this part is essential for the secure assembly of various truck components. Its design and functionality ensure reliable performance under demanding conditions.

Basic Concepts

A Hexagon Flange Head Cap Screw is characterized by its hexagonal head and flange. The hexagonal head allows for efficient torque application using standard tools, ensuring secure fastening. The flange, a flat, circular plate at the head’s base, distributes the load over a larger area, reducing the risk of the screw pulling through the material. This design enhances stability and resistance to loosening under vibration, making it ideal for demanding applications 1.

Role in Truck Operation

In commercial trucks, the Hexagon Flange Head Cap Screw is crucial for the secure assembly of various components and assemblies. It is commonly used in applications requiring high tensile strength and resistance to vibration, such as engine mounts and chassis components. The screw’s design ensures it can withstand dynamic loads and environmental conditions encountered in truck operations 2.

Key Features

The C6204131610 Hexagon Flange Head Cap Screw is crafted from high-quality materials, typically alloy steel, to ensure durability and strength. It features a coarse thread type, providing excellent holding power in various materials. Additionally, the screw may undergo special coatings or treatments, such as zinc plating, to enhance its corrosion resistance and prolong its service life. These features make it an ideal choice for demanding truck applications 3.

Benefits

Using a Hexagon Flange Head Cap Screw in truck applications offers several advantages. The screw’s design enhances fastening security, providing a robust connection that resists loosening due to vibration. This is particularly important in commercial trucks, where components are subjected to constant movement and dynamic loads. Additionally, the ease of installation and removal using standard tools simplifies maintenance procedures, reducing downtime and enhancing operational efficiency 4.

Troubleshooting and Maintenance

Common issues with Hexagon Flange Head Cap Screws include corrosion and stripping. Regular inspection and maintenance can help identify these issues early. To prevent corrosion, ensure that screws are properly coated and that any exposed areas are protected with appropriate sealants. If a screw becomes stripped, it should be replaced to maintain the integrity of the fastening. Adhering to recommended torque specifications during installation also helps prevent over-tightening, which can lead to stripping 5.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established itself as a trusted name in the automotive industry, particularly in diesel engine manufacturing. The company’s commitment to quality, innovation, and customer satisfaction is reflected in its wide range of products, including the C6204131610 Hexagon Flange Head Cap Screw.

Cummins Engine Compatibility with Hexagon Flange Head Cap Screw

The C6204131610 Hexagon Flange Head Cap Screw is designed to be compatible with a range of Cummins engines, ensuring secure fastening and reliable performance. This part is particularly suited for use in the B3.3, QSB3.3 CM2150, and QSB3.3 CM2250 EC engines.

In the B3.3 engine, the Hexagon Flange Head Cap Screw is used in various applications where a robust and dependable fastening solution is required. Its design allows for easy installation and removal, making it ideal for maintenance and repair tasks.

For the QSB3.3 CM2150 and QSB3.3 CM2250 EC engines, the C6204131610 screw is utilized in critical areas where high strength and precision are necessary. The flange head design provides a large bearing surface, distributing the load evenly and preventing damage to the engine components. This ensures that the screw remains tight and secure under operational stresses.

The compatibility of the C6204131610 screw with these engines highlights Cummins’ commitment to providing high-quality, interchangeable parts that maintain the integrity and performance of their engines. This part is engineered to meet the stringent requirements of Cummins’ engine designs, ensuring that it performs reliably in demanding conditions.

Understanding the Role of C6204131610 Hexagon Flange Head Cap Screw in Engine Systems

The C6204131610 Hexagon Flange Head Cap Screw is integral to the assembly and functionality of various engine components. Its design and application are tailored to ensure secure fastening and reliable performance under the demanding conditions within an engine system.

Integration with the Camshaft

In the camshaft assembly, the C6204131610 screw is used to secure the camshaft bearings and sprockets. This ensures that the camshaft operates smoothly, maintaining precise valve timing which is essential for engine performance.

Securing the Connecting Rod and Piston

For the connecting rod and piston assembly, this screw plays a role in fastening components that connect the piston to the crankshaft. Proper securing is vital for the efficient transfer of force from the piston to the crankshaft, contributing to the engine’s power output.

Cylinder Head and Head Assembly

Within the cylinder head and head assembly, the C6204131610 screw is employed to fasten various components such as valve covers and intake manifolds. This ensures a sealed environment, preventing leaks and maintaining optimal combustion efficiency.

Injector Plumbing

In the injector plumbing system, these screws are used to secure injector mounts and fuel rail components. This is important for maintaining fuel delivery precision, which directly impacts engine performance and fuel efficiency.

Long Block Assembly

During the construction of a long block, which includes the cylinder block, crankshaft, pistons, and camshaft, the C6204131610 screw is utilized to fasten various sub-assemblies. This ensures structural integrity and alignment, which are essential for the engine’s overall functionality.

General Use in Engine Parts

Across various engine parts, the C6204131610 Hexagon Flange Head Cap Screw is a versatile fastener. Its application ranges from securing sensor mounts to fastening ancillary components, ensuring that all parts work in unison for optimal engine performance.

Enhancing Performance

By providing a secure and reliable fastening solution, the C6204131610 screw contributes to the overall performance and durability of the engine. Its role in maintaining component alignment and integrity is fundamental to achieving desired engine output and longevity.

Conclusion

The C6204131610 Hexagon Flange Head Cap Screw is a critical component in the assembly and operation of commercial truck engines. Its design, featuring a hexagonal head and flange, ensures secure fastening and resistance to vibration, making it ideal for demanding applications. The screw’s compatibility with various Cummins engines highlights its versatility and reliability. Regular maintenance and proper installation are essential to maximize its performance and longevity, ensuring the secure and efficient operation of truck engines.

-

Robert Bosch GmbH. (2014). Bosch Automotive Handbook 9th Edition. Robert Bosch GmbH.

↩ -

Douglas R. Fehan. (2013). Design of Racing and High-Performance Engines 2004-2013. SAE International.

↩ -

Dominique Bonneau, Aurelian Fatu, and Dominique Souchet. (2014). Internal Combustion Engine Bearings Lubrication in Hydrodynamic Bearings. Wiley-ISTE.

↩ -

John Dixon. (2010). Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning.

↩ -

Robert Bosch GmbH. (2014). Bosch Automotive Handbook 9th Edition. Robert Bosch GmbH.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.