3011714

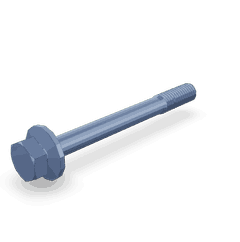

Captive Washer Cap Screw

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3011714 Captive Washer Cap Screw by Cummins is a specialized fastener designed for use in commercial truck maintenance and operation. This part plays a role in securing various components within the truck’s mechanical assemblies, contributing to the overall structural integrity and functionality of the vehicle.

Basic Concepts

A Captive Washer Cap Screw is a type of fastener that includes an integrated washer, which is held in place by a protrusion or step on the screw’s shank. This design ensures that the washer remains attached to the screw during installation, reducing the risk of loss and simplifying the assembly process. In mechanical assemblies, these screws are commonly used to secure components that require a consistent and reliable clamping force, as well as corrosion resistance and durability 1.

Purpose and Function

The 3011714 Captive Washer Cap Screw is specifically designed for use in commercial trucks. It plays a role in securing critical components, such as engine parts, transmission elements, and chassis structures. By providing a stable and consistent clamping force, this screw helps maintain the structural integrity of the truck, ensuring that components remain securely in place under various operating conditions. Its design also contributes to the prevention of galvanic corrosion between dissimilar metals, enhancing the longevity of the fastened components 2.

Key Features

The 3011714 Captive Washer Cap Screw features a robust design that includes a hex-shaped head for easy installation and removal using standard tools. It is manufactured from high-strength materials, typically alloy steel, which provides excellent resistance to wear, corrosion, and fatigue. The integrated washer is designed to distribute the clamping force evenly across the fastened components, reducing the risk of damage and ensuring a secure connection. Additionally, the screw may feature a coating or treatment to further enhance its corrosion resistance and durability in harsh operating environments.

Benefits

Using the 3011714 Captive Washer Cap Screw offers several advantages in commercial truck maintenance and operation. Its design simplifies the installation process by eliminating the need for separate washers, reducing the risk of washer loss and ensuring consistent clamping force. The high-strength material and corrosion-resistant properties contribute to improved reliability and longevity, minimizing the need for frequent replacements. Additionally, the ease of installation and maintenance enhances overall efficiency in truck servicing operations.

Troubleshooting and Maintenance

Common issues with Captive Washer Cap Screws may include loosening due to vibration or thermal expansion, corrosion, and wear. Regular inspection and maintenance are recommended to ensure the screws remain in good condition and continue to provide a secure connection. If corrosion is detected, the affected screws should be replaced to prevent further degradation and potential failure. Additionally, applying a thread locker or anti-seize compound during installation can help mitigate loosening and corrosion issues.

Manufacturer Information

Cummins is a renowned manufacturer with a long-standing reputation for producing high-quality automotive and heavy-duty truck components. The company’s commitment to innovation, quality, and customer satisfaction is evident in its wide range of products, including the 3011714 Captive Washer Cap Screw. Cummins’ expertise in the automotive industry ensures that their components meet the rigorous demands of commercial truck applications, providing reliable performance and durability.

Captive Washer Cap Screw (Part 3011714) in Cummins Engines

The Captive Washer Cap Screw, part number 3011714, manufactured by Cummins, is a critical component in various Cummins engine models. This part is designed to provide secure fastening in applications where a captive washer is integral to the screw’s function, ensuring both reliability and ease of assembly.

G855 Series

The G855 engines, including the G855 CM558 and GTA855 CM558 (CM2358), utilize the 3011714 screw in several key areas. These engines are known for their robust design and are often used in heavy-duty applications. The screw’s secure fastening capability is essential in maintaining the integrity of engine components under high stress and operational conditions.

N14 Series

The N14 engines, which include the N14 CELECT, N14 CELECT PLUS, N14 G, and N14 MECHANICAL, also incorporate the 3011714 screw. These engines are widely used in various industries due to their durability and efficiency. The captive washer cap screw ensures that critical engine parts remain tightly fastened, contributing to the overall performance and longevity of the engine.

NH/NT 855 Series

In the NH/NT 855 engines, the 3011714 screw plays a vital role in securing various components. These engines are designed for applications requiring high power and reliability, such as agricultural and construction equipment. The screw’s design helps maintain the structural integrity of these engines under demanding conditions.

QSN14 Series

The QSN14 engines, specifically the QSN14 CM876 N103 and QSNT14 CM876 N102, also benefit from the use of the 3011714 screw. These engines are engineered for applications that demand superior performance and durability. The screw’s secure fastening ensures that engine components remain properly aligned and secured, contributing to the engine’s overall efficiency and reliability.

Role of Part 3011714 Captive Washer Cap Screw in Engine Systems

The 3011714 Captive Washer Cap Screw is instrumental in securing various components within engine systems, ensuring stability and proper function.

In the context of the Accessory Mounting Plate and Accessory Plate, this screw plays a significant role in attaching these plates to the engine, allowing for the secure mounting of accessories such as alternators, power steering pumps, and air conditioning compressors.

For the Base Engine Mounting and EBM (Engine Block Mounting) Cover, the screw ensures that the engine is firmly attached to the vehicle’s frame, providing necessary support and reducing vibrations during operation.

When dealing with the Front Gear and Front Gear Cover, the 3011714 screw is used to maintain the integrity of the gear case cover mounting, ensuring that the front gear remains aligned and functions smoothly.

In the Gear Case Cover Mounting and Gear Cover, this screw is essential for securing the cover in place, protecting internal components from debris and ensuring that the gear cover remains sealed.

For the Engine Mount, Engine Mounting, Engine Mounting Support, and Engine Mounting, the screw helps in attaching the engine to its supports, providing the necessary stability and reducing stress on the engine during operation.

Lastly, in the Front Engine Support and Engine Supports, the 3011714 screw ensures that the front engine support remains securely attached, contributing to the overall structural integrity of the engine system.

Conclusion

The 3011714 Captive Washer Cap Screw by Cummins is a vital component in commercial truck maintenance and operation. Its robust design, high-strength materials, and integrated washer ensure secure fastening and reliable performance in various engine systems. Regular maintenance and proper installation practices are essential to maximize the benefits of this Cummins part, contributing to the overall efficiency and longevity of commercial trucks.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.