3011829

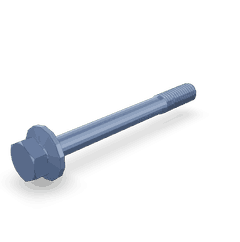

Captive Washer Cap Screw

Cummins®

IN STOCK

9 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3011829 Captive Washer Cap Screw, manufactured by Cummins, is a specialized fastener designed for use in commercial trucks. Cummins is renowned in the automotive industry for its high-quality components that enhance vehicle performance and reliability. This part is integral to the structural integrity and functionality of commercial trucks, playing a significant role in various mechanical assemblies.

Basic Concepts of Captive Washer Cap Screws

A Captive Washer Cap Screw is a type of fastener that includes an integrated washer, which remains attached to the screw during installation. This design ensures that the washer does not become misplaced or lost, simplifying the installation process and enhancing the overall efficiency of mechanical assemblies. These screws are commonly used in applications where consistent and reliable fastening is required, such as in the construction of vehicle frames, engine components, and other critical assemblies 1.

Purpose of the 3011829 Captive Washer Cap Screw in Truck Operations

The 3011829 Captive Washer Cap Screw serves multiple functions in the operation and maintenance of commercial trucks. It is used in applications where secure and durable fastening is necessary to maintain structural integrity. This screw plays a role in connecting various components, ensuring that they remain firmly in place under operational stress. Its design contributes to the overall reliability and safety of the truck, making it a vital component in both routine maintenance and repairs 2.

Key Features

The 3011829 Captive Washer Cap Screw boasts several key features that enhance its performance and reliability. Its design includes an integrated washer, which simplifies installation and reduces the risk of washer loss. The screw is made from high-quality materials, ensuring durability and resistance to corrosion. Additionally, its precise threading and robust construction allow it to withstand significant stress and vibration, making it suitable for demanding applications in commercial trucks 3.

Benefits

Using the 3011829 Captive Washer Cap Screw offers several benefits. The integrated washer design streamlines the installation process, saving time and reducing the likelihood of errors. The screw’s durable construction ensures long-lasting performance, minimizing the need for frequent replacements. Furthermore, its resistance to corrosion and ability to withstand high stress contribute to the overall reliability and safety of the truck.

Installation Process

Proper installation of the 3011829 Captive Washer Cap Screw involves several steps to ensure optimal performance. Begin by selecting the appropriate screw size for the application. Clean the installation area to remove any debris or contaminants that could affect the screw’s performance. Align the screw with the designated hole and use a torque wrench to tighten it to the manufacturer’s specified torque settings. Avoid over-tightening, as this can damage the screw or the surrounding components. Regularly inspect the installation to ensure the screw remains secure and functions as intended.

Troubleshooting Common Issues

Common issues with Captive Washer Cap Screws include loosening, corrosion, and damage from over-tightening. To address these problems, regularly inspect the screws for signs of wear or corrosion. If a screw appears loose, re-tighten it to the specified torque settings. In cases of significant corrosion or damage, replace the screw with a new one to maintain the integrity of the assembly. Proper maintenance and timely replacements can prevent more severe issues and ensure the continued reliability of the truck.

Maintenance Tips

Regular maintenance of the 3011829 Captive Washer Cap Screw is essential for ensuring longevity and optimal performance. Inspect the screws periodically for signs of wear, corrosion, or loosening. Clean the installation area to prevent the buildup of debris and contaminants. Follow the manufacturer’s torque specifications during installation and re-tightening to avoid over-tightening. Replace any damaged or corroded screws promptly to maintain the structural integrity and functionality of the truck.

Cummins: A Brief Overview

Cummins is a renowned manufacturer with a rich history in the automotive industry. The company is known for its commitment to quality, innovation, and reliability in producing automotive components. Cummins’ reputation is built on its dedication to developing high-performance parts that enhance the efficiency and durability of vehicles. The company’s focus on research and development ensures that its products meet the evolving needs of the industry, providing customers with trusted and dependable components for their commercial trucks.

Cummins Part 3011829 Captive Washer Cap Screw in Engine Applications

The Cummins part 3011829 Captive Washer Cap Screw is a critical component in various engine configurations, ensuring secure fastening and stability. This part is meticulously designed to meet the stringent requirements of high-performance engines, providing reliability and durability in demanding environments.

K-Series Engines

The K19, K38, and K50 engines are part of Cummins’ K-Series, known for their robust construction and efficiency. The Captive Washer Cap Screw (part 3011829) is integral in these engines, securing various components and ensuring that the engine operates smoothly under high stress.

KTA19 Series

The KTA19GC engine, part of the KTA19 series, is designed for heavy-duty applications. The Captive Washer Cap Screw is used extensively in this engine to maintain the integrity of critical assemblies, providing a reliable fastening solution that withstands the rigors of continuous operation.

N14 Celect Plus

The N14 Celect Plus engine is renowned for its performance and efficiency. The Captive Washer Cap Screw is essential in this engine, securing components that are subject to high loads and vibrations, ensuring that the engine maintains its structural integrity.

NH/NT Series

The NH/NT 855 engines are part of Cummins’ NH/NT series, which is widely used in various industrial applications. The Captive Washer Cap Screw is a key component in these engines, providing the necessary fastening strength to keep the engine’s components securely in place.

QSK Series

The QSK19 CM500 and QSK19G engines are part of Cummins’ QSK Series, known for their power and efficiency. The Captive Washer Cap Screw is used in these engines to secure various parts, ensuring that the engine can handle the high stresses and demands of heavy-duty operations.

V-Series Engines

The V28 and VTA903 CM2250 V105 engines are part of Cummins’ V-Series, which is designed for high-performance applications. The Captive Washer Cap Screw is a vital component in these engines, providing the necessary fastening strength to maintain the structural integrity of the engine under extreme conditions.

Each of these engines relies on the Captive Washer Cap Screw to ensure that all components are securely fastened, providing the necessary stability and reliability for optimal performance.

Role of Part 3011829 Captive Washer Cap Screw in Engine Systems

The 3011829 Captive Washer Cap Screw is instrumental in securing and maintaining the integrity of various engine components. Its application spans across multiple systems, ensuring that parts remain firmly in place under operational stresses.

Aftercooler Systems

In the aftercooler conversion kit and aftercooler cooler conversion kit, the 3011829 screw is used to fasten the aftercooler top level number components. This ensures that the aftercooler remains securely attached, allowing for efficient cooling of the compressed air from the turbocharger.

Air Management Components

For the air crossover connection mounting and air crossover mounting kit, the screw plays a vital role in attaching the air crossover pipes. This is essential for directing airflow between different parts of the engine, such as the air intake manifold and air intake mfld.

The air intercooler mounting, air manifold kit, air mounting crossover, air mounting intercooler, and air mounting manifold all rely on the 3011829 screw to ensure that these components are tightly secured. This is important for maintaining optimal airflow and cooling efficiency within the engine system.

Camshaft and Cooling Systems

In the camshaft assembly, the screw is used to secure various brackets and mounts, ensuring the camshaft operates smoothly without undue vibration.

For the engine cooling system and engine oil cooler, the screw is employed to fasten components such as the heat exchanger and oil cooler water plumbing. This secure attachment is necessary for maintaining the efficiency of the cooling process, preventing leaks, and ensuring consistent engine temperature.

Turbocharger and Sea Water Connections

In the turbocharger arrangement and turbocharger mounting, the 3011829 screw is critical for securing the turbocharger to the engine block. This ensures that the turbocharger operates efficiently under high-stress conditions.

The sea water mounting connection also utilizes this screw to attach components that interface with seawater cooling systems, ensuring a secure and leak-free connection.

Additional Applications

The screw is also found in the hydro mechanical step and injector systems, where it secures various mounts and brackets. This ensures that these components function correctly under the dynamic conditions of engine operation.

Conclusion

In summary, the 3011829 Captive Washer Cap Screw is a versatile fastener that contributes to the reliable operation of a wide range of engine components, from cooling systems to air management and turbocharger assemblies. Its robust design, ease of installation, and resistance to corrosion make it an essential component in the maintenance and operation of commercial trucks.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.