This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

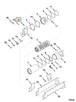

The Captive Washer Cap Screw Assembly, specifically Part #3012474 by Cummins, is a component designed for use in heavy-duty trucks. Cummins, a well-established manufacturer in the automotive industry, produces this assembly to meet the demanding requirements of truck mechanics and operators. This part is integral to the structural and functional integrity of heavy-duty trucks, ensuring that various components are securely fastened and maintained 1.

Basic Concepts

A Captive Washer Cap Screw Assembly consists of a screw, a washer, and a cap that holds the washer in place. This design ensures that the washer remains attached to the screw during installation, reducing the risk of loss and ensuring consistent torque application. Within a truck’s mechanical system, this assembly plays a role in securing components, distributing load, and preventing wear and tear on fastened parts 2.

Purpose and Role in Truck Operation

The 3012474 Captive Washer Cap Screw Assembly is designed to secure various components within a truck’s structure. Its role includes fastening panels, brackets, and other parts that require a secure and durable connection. By providing a stable attachment point, this assembly contributes to the overall structural integrity of the truck, ensuring that components remain in place under various operating conditions 3.

Key Features

The 3012474 Captive Washer Cap Screw Assembly features a design that integrates a screw with a captive washer, held in place by a cap. This design enhances the assembly’s performance by ensuring that the washer does not detach during installation. The materials used in its construction are selected for their durability and resistance to corrosion, making the assembly suitable for the harsh environments often encountered by heavy-duty trucks 4.

Benefits

The benefits of using the 3012474 Captive Washer Cap Screw Assembly include improved reliability due to its secure design, ease of installation thanks to the captive washer feature, and maintenance advantages such as reduced need for re-tightening or replacement of lost washers. These attributes contribute to the overall efficiency and longevity of the truck’s mechanical systems.

Installation Process

Installing the 3012474 Captive Washer Cap Screw Assembly involves aligning the screw with the designated fastening point, ensuring the cap is properly oriented, and tightening the screw to the recommended torque specification. Best practices include verifying that the washer is correctly positioned before final tightening and avoiding over-tightening, which could damage the assembly or the fastened components.

Troubleshooting and Maintenance

Common issues with the 3012474 Captive Washer Cap Screw Assembly may include loosening over time or corrosion in harsh environments. Troubleshooting involves checking for proper torque, ensuring the washer is intact and correctly positioned, and inspecting for signs of corrosion or wear. Maintenance tips include regular inspection of the assembly for signs of wear, ensuring it remains tight, and replacing the assembly if significant corrosion or damage is observed.

Manufacturer - Cummins

Cummins is a reputable manufacturer in the automotive industry, known for its commitment to quality and innovation. With a history of producing reliable and high-performance components, Cummins has established a strong reputation among truck mechanics and operators. The company’s focus on research and development ensures that its products, including the 3012474 Captive Washer Cap Screw Assembly, meet the evolving needs of the heavy-duty truck industry.

Captive Washer Cap Screw Assembly (Part 3012474) in Cummins Engines

The Captive Washer Cap Screw Assembly, part number 3012474, is a critical component in various Cummins engines, ensuring secure fastening and stability. This part is designed to fit seamlessly into the engine’s architecture, providing a reliable connection between different parts.

K-Series Engines

In the K-Series engines, such as the K19, K38, and K50, the 3012474 part is used to secure various components, ensuring that the engine operates smoothly and efficiently. These engines are known for their robust design and are often used in heavy-duty applications.

QSK Series Engines

The QSK Series engines, including the QSK19 CM2350 K105, QSK19 CM2350 K114, QSK19 CM2350 K144G, QSK19 CM500, QSK19 CM850 MCRS, QSK19G, QSK45 CM500, QSK60 CM500, and QSK78 CM500, also utilize the 3012474 part. This assembly is crucial in maintaining the integrity of the engine’s structure, particularly in the mounting and fastening of critical components.

QSM Series Engines

The QSM11 CM570 engine incorporates the 3012474 part to ensure that all fastened components remain secure under high operational stresses. This engine is designed for demanding applications, and the use of this screw assembly is vital for its performance.

Other Cummins Engines

The 3012474 part is also compatible with other Cummins engines such as the 6C8.3, G855, N14 MECHANICAL, NH/NT 855, V28, and V903. In these engines, the screw assembly is used to fasten various parts, ensuring that the engine maintains its structural integrity and operational efficiency.

This captive washer cap screw assembly is a testament to Cummins’ commitment to quality and reliability, ensuring that all its engines perform optimally under various conditions.

Role of Part 3012474 Captive Washer Cap Screw Assembly in Engine Systems

The Part 3012474 Captive Washer Cap Screw Assembly is instrumental in ensuring the secure and reliable attachment of various components within engine systems. Its application spans across multiple critical areas, enhancing both the functionality and durability of the engine.

Accessory Mounting Drive

In the accessory mounting drive, the Captive Washer Cap Screw Assembly is used to fasten accessories securely to the engine. This ensures that accessories such as alternators, power steering pumps, and air conditioning compressors remain firmly in place, reducing the risk of vibration-induced detachment.

Aftercooler Kit

For the aftercooler kit, this assembly plays a role in attaching the aftercooler to the engine and other components. It ensures a tight seal and proper alignment, which is essential for efficient cooling of the compressed air from the turbocharger.

Air Intake Manifold

Within the air intake manifold, the Captive Washer Cap Screw Assembly is employed to secure the manifold to the engine block. This connection is vital for maintaining the integrity of the air pathway, ensuring optimal airflow into the combustion chambers.

Corrosion Resistor

When integrating corrosion resistors into the engine system, this screw assembly helps in mounting these components securely. It prevents any movement that could compromise the resistor’s effectiveness in protecting metal surfaces from corrosion.

Crankcase Breather Arrangement

In the crankcase breather arrangement, the assembly is used to attach the breather components to the engine. This ensures that crankcase ventilation is maintained, allowing for the safe release of gases and moisture, which prevents pressure build-up and contamination.

Engine Oil Cooler

For the engine oil cooler, the Captive Washer Cap Screw Assembly is critical in securing the cooler to its mounting points. This ensures efficient heat exchange and maintains the oil at optimal temperatures for engine performance.

Front Engine Support

In the front engine support system, this assembly is utilized to fasten the support structure to the engine and chassis. This connection is essential for absorbing vibrational forces and ensuring the engine remains stable within the vehicle.

Fuel Pump and Fuel Pump Mounting Support

The assembly is integral in securing the fuel pump and its mounting support to the engine. This ensures a stable fuel supply system, which is crucial for consistent engine operation.

Kit Assembly Cooler

For the kit assembly cooler, the Captive Washer Cap Screw Assembly is used to attach various components within the kit to the engine. This ensures that all parts are securely in place, facilitating efficient cooling processes.

Lube Oil Cooler and Lubricating Oil Cooler

In both the lube oil cooler and lubricating oil cooler systems, this assembly is employed to fasten the coolers to their respective mounting points. This ensures effective heat dissipation from the lubrication oil, maintaining its viscosity and performance.

Lubricating Oil Mounting Filter and Pump

The assembly is used to secure the lubricating oil mounting filter and pump to the engine. This ensures that the oil filtration and pumping processes are reliable and uninterrupted.

Lubricating Oil Top Level Assembly Pump

For the lubricating oil top level assembly pump, the Captive Washer Cap Screw Assembly ensures that the pump is securely attached, allowing for precise control of oil levels within the engine.

Lubricating Suction Connection

In the lubricating suction connection, this assembly is used to fasten the connection points securely. This ensures a consistent and reliable oil supply to the engine’s moving parts.

Mounting and Fuel Bypass Tube

The assembly is crucial in securing the mounting and fuel bypass tube to the engine. This ensures that fuel bypass mechanisms operate correctly, maintaining fuel system integrity.

Noise Panel Mtg

For noise panel mounting, the Captive Washer Cap Screw Assembly is used to attach noise reduction panels to the engine compartment. This helps in reducing engine noise and improving the overall acoustic environment.

Oil Bypass Filter

In the oil bypass filter system, this assembly is employed to secure the filter to its mounting points. This ensures that the bypass function operates effectively, protecting the engine from contaminants.

Oil Cooler

The assembly is used to fasten the oil cooler to the engine, ensuring efficient cooling of the lubrication oil and maintaining its optimal performance characteristics.

Rocker Hsg Cov and Rocker Lever Mounting Cover

For the rocker housing cover and rocker lever mounting cover, the Captive Washer Cap Screw Assembly ensures these components are securely attached to the engine. This maintains the integrity of the valve train system.

Turbocharger Conversion Kit

In the turbocharger conversion kit, this assembly is used to attach various components to the engine. This ensures that the turbocharger system is securely integrated, enhancing engine performance and efficiency.

Valve Mounting Cover

The assembly is utilized to secure the valve mounting cover to the engine. This ensures that the valve components are properly housed and protected, contributing to reliable engine operation.

Water Connection Kit

Finally, in the water connection kit, the Captive Washer Cap Screw Assembly is used to fasten water connection points securely. This ensures efficient coolant flow and temperature regulation within the engine.

Conclusion

The 3012474 Captive Washer Cap Screw Assembly by Cummins is a vital component in the maintenance and operation of heavy-duty trucks and engines. Its design ensures secure fastening, durability, and ease of installation, contributing to the overall efficiency and reliability of the vehicle. Cummins’ commitment to quality and innovation is evident in this part, making it a trusted choice for truck mechanics and operators.

-

Andrew Brown Jr, Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles, National Academy of Sciences, 2010.

↩ -

Allan Bonnick and Derek Newbold, A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition, Elsevier Ltd, 2011.

↩ -

Libby Osgood, Gayla Cameron, and Emma Christensen, Engineering Mechanics: Statics, Creative Commons, 2024.

↩ -

Zhiyu Han, Simulation and Optimization of Internal Combustion Engines, SAE International, 2022.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.