This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Captive Washer with Cap Screw Assembly, identified by part number 3012480, is a component manufactured by Cummins, a well-established name in the automotive industry. This assembly is designed for use in heavy-duty trucks, where it plays a role in ensuring the mechanical integrity and operational efficiency of various truck systems.

Basic Concepts

The Captive Washer with Cap Screw Assembly is engineered based on fundamental mechanical principles that ensure secure fastening and reliable performance. The assembly includes a washer that is integrated with a cap screw, which is a type of bolt with a built-in head. This design allows for efficient load distribution and enhanced fastening security, which are important in the demanding environments typical of heavy-duty trucks.

Purpose and Role in Truck Operation

The primary purpose of the Captive Washer with Cap Screw Assembly is to provide a secure and durable fastening solution in heavy-duty truck applications. It is used to join components that require a high degree of stability and resistance to vibration and stress. By ensuring that parts remain firmly attached, the assembly contributes to the overall safety and efficiency of truck operations.

Key Features

The Captive Washer with Cap Screw Assembly features a design that includes a cap screw with an integrated washer. This design eliminates the need for separate washers, reducing the risk of washer loss during installation and ensuring consistent load distribution. The materials used in the assembly are selected for their strength and durability, making them suitable for the harsh conditions encountered in heavy-duty truck applications. Additionally, the assembly may include features such as corrosion-resistant coatings to enhance its performance in various environments.

Benefits

The Captive Washer with Cap Screw Assembly offers several advantages. Its integrated design simplifies the installation process, reducing the likelihood of errors and ensuring a consistent fastening solution. The assembly’s durable materials and design contribute to improved reliability and longevity, even in demanding truck environments. Furthermore, the elimination of separate washers reduces the risk of washer loss or misplacement, streamlining the maintenance and repair processes.

Installation Process

Installing the Captive Washer with Cap Screw Assembly involves several steps to ensure proper fastening and performance. First, the appropriate hole size should be prepared in the components to be joined. The cap screw is then inserted through the hole, and a compatible tool, such as a torque wrench, is used to tighten the screw to the manufacturer’s specified torque settings. This ensures that the assembly is securely fastened without over-tightening, which could damage the components or the assembly itself.

Common Applications

The Captive Washer with Cap Screw Assembly is versatile and can be found in various applications within heavy-duty trucks. It is commonly used in the fastening of engine components, chassis parts, and other critical systems where secure and durable fastening is required. Its design makes it suitable for applications that experience significant vibration, stress, and environmental exposure.

Troubleshooting and Maintenance

To ensure the longevity and optimal performance of the Captive Washer with Cap Screw Assembly, regular maintenance and troubleshooting are recommended. Inspecting the assembly for signs of wear, corrosion, or loosening can help identify potential issues before they lead to failures. If any issues are detected, the assembly should be tightened to the specified torque settings or replaced if necessary. Additionally, keeping the assembly clean and free of debris can help maintain its performance and durability.

About Cummins

Cummins is a renowned manufacturer in the automotive industry, known for its high-quality truck components and engines. With a history of innovation and a commitment to excellence, Cummins has established a reputation for producing reliable and durable parts that meet the demanding requirements of heavy-duty truck applications. The company’s focus on quality, performance, and customer satisfaction has made it a trusted name in the industry.

Captive Washer with Cap Screw Assembly (Part 3012480) in Cummins Engines

The Captive Washer with Cap Screw Assembly, identified by part number 3012480, is a component in various Cummins engine models. This assembly is designed to secure and stabilize different parts within the engine, ensuring optimal performance and longevity.

NH/NT 855 Engines

In the NH/NT 855 engines, the 3012480 assembly plays a role in maintaining the integrity of the engine’s internal structure. It is typically used in areas where precise alignment and fastening are essential, such as securing engine mounts, brackets, or other critical components. The cap screw provides the necessary clamping force, while the captive washer ensures even distribution of pressure, preventing damage to the fastened parts.

The assembly’s design allows for easy installation and removal, which is vital during maintenance and repair operations. Its robust construction ensures that it can withstand the high stresses and vibrations inherent in engine operation, contributing to the overall reliability of the NH/NT 855 engines.

Grouping of Engines

The 3012480 Captive Washer with Cap Screw Assembly is not limited to the NH/NT 855 engines alone. Cummins has designed this part to be compatible with a range of their engine models, ensuring a standardized approach to engine assembly and maintenance. This standardization facilitates easier inventory management and reduces the complexity of sourcing replacement parts.

By using the 3012480 assembly across multiple engine models, Cummins ensures that the same high-quality fastening solution is applied consistently, enhancing the overall performance and durability of their engines.

Role of Part 3012480 Captive Washer with Cap Screw Assembly in Engine Systems

The Captive Washer with Cap Screw Assembly is an integral component in various engine systems, ensuring secure and efficient operation.

In engine mounting, this assembly is used to fasten the engine securely to its mounting brackets. It provides a stable connection, absorbing vibrations and ensuring that the engine remains firmly in place during operation.

For engine rotation, the assembly is employed in attaching components that require rotational stability. It ensures that parts rotate smoothly without wobbling, maintaining the engine’s balance and efficiency.

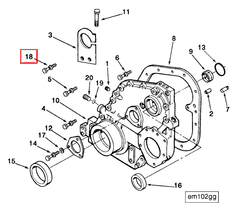

In the context of gear cover mounting, the captive washer with cap screw assembly is utilized to secure the gear cover to the engine block. This ensures that the gear cover remains in place, protecting internal components from contaminants and ensuring proper lubrication.

The lubricating filter pump and lubricating oil filter pump systems benefit from this assembly by securing pump components together. It ensures that the pump operates efficiently, maintaining consistent oil flow and filtration.

Similarly, in the lubricating oil pump system, the assembly is used to fasten pump components, ensuring that the pump can deliver oil under pressure to various engine parts, enhancing lubrication and reducing wear.

In systems involving recirculation, the assembly helps in securing components that manage the flow of fluids back into the system, ensuring that recirculation processes are smooth and uninterrupted.

For the exhaust system, the assembly is used to secure exhaust components, ensuring that the exhaust path is sealed properly to prevent leaks and maintain efficient emission control.

In terms of support structures within the engine, the captive washer with cap screw assembly provides the necessary fastening for support brackets and frames, ensuring that these structures can withstand the stresses of engine operation.

Lastly, in the front engine components, this assembly is crucial for securing front-mounted accessories and parts, ensuring they are held firmly in place and function correctly.

Overall, the Captive Washer with Cap Screw Assembly plays a role in maintaining the integrity and efficiency of various engine systems by providing secure and reliable fastening solutions.

Conclusion

The Captive Washer with Cap Screw Assembly (Part #3012480) by Cummins is a critical component in heavy-duty truck and engine applications. Its design, featuring an integrated washer and cap screw, ensures secure fastening, efficient load distribution, and enhanced durability. The assembly is used in various applications within engines, including engine mounting, rotation, gear cover mounting, lubrication systems, recirculation, exhaust, and support structures. Regular maintenance and proper installation are essential to ensure the longevity and optimal performance of this part. Cummins’ commitment to quality and innovation is reflected in the design and functionality of the 3012480 assembly, making it a reliable choice for demanding truck and engine environments.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.