3017049

Captive Washer Cap Screw

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3017049 Captive Washer Cap Screw is a specialized fastener designed for use in commercial trucks. It plays a role in securing various components within the truck’s assembly, ensuring stability and reliability under demanding operational conditions. This screw is particularly valued in the commercial trucking industry for its robust design and ease of use.

Basic Concepts

A Captive Washer Cap Screw is a type of fastener that incorporates a washer directly into the screw head. This design eliminates the need for separate washers, streamlining the installation process and reducing the risk of washer loss during assembly 1. In mechanical assemblies, these screws are used to provide a secure and consistent clamping force, which is important for the integrity and performance of the connected components.

Purpose of the 3017049 Captive Washer Cap Screw

The 3017049 Captive Washer Cap Screw plays a role in the operation and maintenance of commercial trucks by providing a reliable fastening solution for various applications. It is commonly used in engine components, chassis assemblies, and other critical areas where secure fastening is required. The screw’s design ensures that it can withstand the vibrations and stresses encountered in heavy-duty truck operations, contributing to the overall durability and performance of the vehicle 2.

Key Features

The Cummins 3017049 Captive Washer Cap Screw features a durable material composition, typically consisting of high-strength steel, which enhances its resistance to wear and corrosion. The screw’s design includes a captive washer that is integrated into the head, ensuring consistent clamping force and reducing the likelihood of washer displacement. Additionally, the screw is engineered with precision threading to facilitate easy installation and reliable performance 3.

Benefits

Using the 3017049 Captive Washer Cap Screw offers several advantages. Its integrated washer design simplifies the installation process, saving time and reducing the risk of errors. The screw’s high-strength material composition ensures improved reliability and durability, even under demanding conditions. Furthermore, the consistent clamping force provided by the captive washer enhances the performance and longevity of the fastened components.

Installation Process

Proper installation of the 3017049 Captive Washer Cap Screw involves several steps. Begin by ensuring that the mating surfaces are clean and free of debris. Align the screw with the designated hole and use a torque wrench to tighten it to the manufacturer’s specified torque settings. It is important to avoid over-tightening, which can lead to damage, and to ensure that the screw is perpendicular to the surface to maintain optimal clamping force. Regularly inspect the screw for signs of wear or damage during routine maintenance checks.

Troubleshooting and Maintenance

Common issues with the 3017049 Captive Washer Cap Screw may include loosening due to vibrations or corrosion. To address these problems, regularly inspect the screws during maintenance intervals and re-tighten as necessary. If corrosion is detected, consider applying a corrosion-resistant coating to the screw and surrounding areas. Additionally, replacing worn or damaged screws promptly will help maintain the integrity of the truck’s components.

Compatibility and Use Cases

The 3017049 Captive Washer Cap Screw is designed for use in various commercial truck applications. It is compatible with a range of engine and chassis components, providing a versatile fastening solution. Typical use cases include securing engine mounts, chassis brackets, and other critical assemblies where reliable fastening is required.

Safety Considerations

When handling and installing the 3017049 Captive Washer Cap Screw, it is important to follow safety guidelines to protect personnel and ensure the integrity of the truck’s components. Wear appropriate personal protective equipment, such as gloves and safety glasses, to prevent injuries. Use the correct tools and follow torque specifications to avoid over-tightening, which can lead to component damage. Additionally, ensure that the work area is clean and free of hazards to maintain a safe working environment.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and reliability in the commercial truck industry. The company’s extensive product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding requirements of heavy-duty applications.

Role of Part 3017049 Captive Washer Cap Screw in Engine Systems

The 3017049 Captive Washer Cap Screw is integral to the assembly and secure functioning of various engine components. Its application ensures that parts remain firmly in place, thereby contributing to the overall stability and performance of the engine system.

Base Parts

In the assembly of base parts, the Captive Washer Cap Screw plays a significant role in fastening components that form the foundational structure of the engine. It secures these parts, ensuring they withstand the vibrations and stresses encountered during engine operation.

Engine Shipping Bar

When engines are transported, the shipping bar is used to stabilize the engine within its crate. The Captive Washer Cap Screw is employed to attach the shipping bar securely, preventing any movement that could damage the engine during transit.

Fuel Pump

The fuel pump is a vital component responsible for delivering fuel from the tank to the engine. The Captive Washer Cap Screw is used to mount the fuel pump securely within the fuel system, ensuring it operates efficiently without any risk of detachment.

Fuel Pump Drive Mounting

For the fuel pump drive system, the Captive Washer Cap Screw is essential in mounting the drive mechanism. This ensures the drive remains aligned and functions correctly, which is important for the consistent delivery of fuel.

Oil Mounting Pan

The oil mounting pan collects and stores oil within the engine system. The Captive Washer Cap Screw is utilized to attach the pan securely, preventing oil leaks and ensuring the pan remains in place under the dynamic conditions of engine operation.

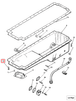

Oil Pan

Similarly, the oil pan, which houses the engine’s lubricant, relies on the Captive Washer Cap Screw for secure attachment. This fastening is vital for maintaining the integrity of the oil system and preventing any oil loss.

Oil Pan and Dipstick

The assembly of the oil pan and dipstick also benefits from the use of the Captive Washer Cap Screw. It ensures that the dipstick is properly aligned and the oil pan is sealed effectively, facilitating accurate oil level readings and maintaining system integrity.

Oil Pan Mounting

In the overall mounting of the oil pan to the engine block, the Captive Washer Cap Screw provides the necessary tension and security. This is important for the pan’s stability and the prevention of oil leaks.

Pan Oil

Finally, in systems where pan oil is utilized, the Captive Washer Cap Screw ensures that all components related to the oil pan are securely fastened. This includes any additional fittings or sensors that may be attached to the pan, ensuring they function correctly and remain in place.

Conclusion

The Cummins 3017049 Captive Washer Cap Screw is a critical component in the assembly and maintenance of commercial trucks and engines. Its robust design, ease of use, and reliable performance make it an essential part for ensuring the stability and efficiency of various engine components. Proper installation, regular maintenance, and adherence to safety guidelines are important for maximizing the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.