3017051

Captive Washer Cap Screw

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

Minimum Quantity 2

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Captive Washer Cap Screw, part number 3017051, is a component utilized in various applications, including heavy-duty trucks. Manufactured by Cummins, a well-established name in the automotive industry, this screw is designed to meet the rigorous demands of truck operations. Cummins is recognized for its commitment to quality and innovation, providing reliable components that enhance the performance and durability of vehicles.

Basic Concepts of Captive Washer Cap Screws

A Captive Washer Cap Screw is a type of fastener that includes an integrated washer. This design ensures that the washer remains in place during installation, reducing the risk of loss and simplifying the assembly process 1. In the automotive industry, these screws are commonly used in applications where vibration resistance and secure fastening are required. They play a role in maintaining the integrity of various components by providing a stable and consistent clamping force.

Purpose of the 3017051 Captive Washer Cap Screw in Truck Operations

The 3017051 Captive Washer Cap Screw is employed in heavy-duty trucks to fasten components that are subject to significant stress and vibration. Its design allows for efficient and reliable fastening, which is vital for the safe and effective operation of the vehicle. By securing critical parts, this screw contributes to the overall stability and performance of the truck, ensuring that components remain in place under demanding conditions.

Key Features of the 3017051 Captive Washer Cap Screw

The 3017051 Captive Washer Cap Screw is engineered with specific design elements and materials to enhance its performance and durability. It features a captive washer that is integrated into the screw, ensuring that the washer does not become dislodged during installation. The screw is typically made from high-strength materials, such as alloy steel, which provides resistance to corrosion and wear. Additionally, the screw may have a coated finish to further protect against environmental factors and improve longevity 2.

Benefits of Using the 3017051 Captive Washer Cap Screw

The use of the 3017051 Captive Washer Cap Screw offers several advantages. Its design simplifies the installation process by eliminating the need to separately handle and position the washer. This can lead to increased efficiency during maintenance and repair operations. The screw’s robust construction and materials contribute to its reliability, ensuring that it can withstand the stresses of heavy-duty truck applications. Furthermore, the integrated washer provides consistent clamping force, which enhances the security of fastened components 3.

Installation and Usage Guidelines

To ensure optimal performance, the 3017051 Captive Washer Cap Screw should be installed according to the following guidelines:

- Ensure the mating surface is clean and free of debris.

- Align the screw with the designated hole.

- Use the appropriate tool to drive the screw until it is fully seated.

- Check that the screw is secure and the washer is properly positioned.

Troubleshooting Common Issues

Common issues with Captive Washer Cap Screws may include loosening due to vibration or corrosion. To address these problems:

- Inspect screws regularly for signs of wear or corrosion.

- Tighten screws as necessary to maintain secure fastening.

- Replace screws that show significant wear or damage to prevent failure.

Maintenance Tips

To prolong the lifespan and ensure the continued effectiveness of the 3017051 Captive Washer Cap Screw, consider the following maintenance practices:

- Perform regular inspections to check for signs of wear, corrosion, or loosening.

- Clean the screw and surrounding area to remove dirt and debris that may contribute to corrosion.

- Apply a protective coating or lubricant, if recommended by the manufacturer, to enhance resistance to environmental factors.

Cummins: A Brief Overview

Cummins is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is committed to providing high-quality, innovative solutions for the automotive industry. The company’s product range includes engines, powertrains, and related components, all designed to meet the demanding requirements of various applications. Cummins’ dedication to quality and customer satisfaction has established it as a trusted name in the industry.

Captive Washer Cap Screw 3017051 in Cummins Engines

The Captive Washer Cap Screw part number 3017051 is a critical component in various Cummins engines, ensuring secure fastening and stability. This part is integral to the assembly and maintenance of several engine models, providing a reliable connection between different parts.

ISM Series Engines

In the ISM series, the Captive Washer Cap Screw 3017051 is utilized in the following engines:

- ISM CM570

- ISM CM570/870

- ISM CM876

- ISM11 CM876 SN

These engines are known for their robust performance and efficiency, and the cap screw plays a vital role in maintaining the structural integrity of the engine components.

K Series Engines

For the K series engines, the part 3017051 is used in:

- K19

- K38

- K50

These engines are designed for heavy-duty applications, and the cap screw ensures that all parts are securely fastened, contributing to the overall durability and reliability of the engine.

L10 Series Engines

In the L10 series, the Captive Washer Cap Screw is used across various configurations:

- L10 CELECT

- L10 GAS

- L10 MECHANICAL

This part is essential in maintaining the alignment and stability of the engine components, ensuring smooth operation and longevity.

M11 Series Engines

For the M11 series engines, the part 3017051 is used in:

- M11 CELECT

- M11 CELECT PLUS

- M11 MECHANICAL

The cap screw is crucial in these engines, providing a secure fastening mechanism that is essential for the proper functioning of the engine.

N14 Series Engines

In the N14 series, the Captive Washer Cap Screw is used in:

- N14 CELECT

- N14 CELECT PLUS

- N14 MECHANICAL

These engines benefit from the cap screw’s ability to maintain tight and secure connections, which is vital for the engine’s performance and reliability.

QSK Series Engines

For the QSK series engines, the part 3017051 is used in:

- QSK19 CM500

- QSK45 CM500

- QSK60 CM500

The cap screw is essential in these high-performance engines, ensuring that all components are securely fastened and aligned.

QSM and QSNT Series Engines

In the QSM and QSNT series engines, the Captive Washer Cap Screw is used in:

- QSM11 CM570

- QSM11 CM876

- QSN14 CM876 N103

- QSNT14 CM876 N102

These engines rely on the cap screw to maintain the integrity of the engine assembly, ensuring that all parts are securely fastened and aligned.

NH/NT 855 and V28 Engines

The part 3017051 is also used in the following engines:

- NH/NT 855

- V28

In these engines, the cap screw ensures that the engine components are securely fastened, contributing to the overall performance and reliability of the engine.

Role of Part 3017051 Captive Washer Cap Screw in Engine Systems

The 3017051 Captive Washer Cap Screw is integral to the assembly and securement of various components within engine systems. Its design ensures a reliable fastening solution that maintains the integrity and efficiency of the engine’s operation.

Aftercooler Systems

In aftercooler setups, whether for automotive applications or multi-unit systems, the 3017051 screw is used to secure the aftercooler to its mounting points. This ensures that the aftercooler remains firmly in place, allowing for optimal cooling of the compressed air before it enters the engine. The screw’s captive washer feature prevents loss of the washer during installation, maintaining the seal and preventing leaks.

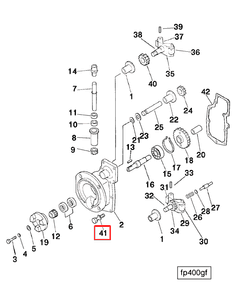

Fuel System Components

For fuel-related components such as the fuel pump, fuel adapter kit, and fuel top-level assembly pump, the 3017051 screw plays a key role in securing these parts to the engine or fuel system framework. This is particularly important in calibration processes where precise positioning and secure fastening are required to ensure accurate fuel delivery and engine performance.

Engine Control and Calibration

When dealing with engine control modules and calibration kits, the 3017051 screw is employed to attach sensors, regulators, and other critical components. Its use ensures that these parts remain in the correct position, which is essential for the accurate reading of engine parameters and the effective calibration of fuel and air mixtures.

Intake Manifold and Performance Parts

In the assembly of intake manifolds and performance parts, the 3017051 screw helps in securing these components to the engine block. This is vital for maintaining the airtight seals necessary for optimal airflow into the engine, directly influencing its performance and efficiency.

Plumbing and Pressure-Time Fuel Pumps

For plumbing applications within the engine system, including pressure-time fuel pumps, the 3017051 screw is used to secure fittings and connections. This ensures that the fuel lines and associated components are held firmly in place, preventing leaks and ensuring consistent fuel pressure throughout the system.

General Application Across Engine Systems

Across various engine systems, from non-AFC auto fuel pumps to performance parts and pressure regulators, the 3017051 Captive Washer Cap Screw provides a versatile fastening solution. Its application ensures that components are securely attached, contributing to the overall reliability and performance of the engine.

Conclusion

The 3017051 Captive Washer Cap Screw by Cummins is a vital component in the automotive industry, particularly for heavy-duty truck applications. Its design, featuring an integrated washer, simplifies installation and ensures secure fastening, which is crucial for the stability and performance of vehicles. The screw’s robust construction and materials make it reliable under demanding conditions, contributing to the longevity and efficiency of engine systems. Regular maintenance and proper installation practices are essential to maximize the benefits of this component.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.