This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3019574 Captive Washer Cap Screw by Cummins is a component used in the maintenance and assembly of heavy-duty trucks. Cummins, a well-established manufacturer in the automotive industry, produces this screw to meet the demanding requirements of commercial truck applications. This part is specifically designed for use in various truck components, ensuring reliable performance and durability.

Basic Concepts of Captive Washer Cap Screws

A Captive Washer Cap Screw is a type of fastener that includes an integrated washer. This design allows the washer to remain attached to the screw, which simplifies the installation process and reduces the risk of losing the washer. The washer plays a role in providing a sealing surface, which helps to distribute the load and prevent the screw from loosening due to vibration or other dynamic forces encountered in mechanical assemblies 1.

Purpose of the 3019574 Captive Washer Cap Screw in Truck Operation

The 3019574 Captive Washer Cap Screw is utilized in the operation and maintenance of heavy-duty trucks to secure various components and systems. It is applied in areas where a secure, vibration-resistant connection is required. The screw’s design ensures that it remains tight and does not back out, which is particularly important in the harsh operating conditions typical of commercial trucks 2.

Key Features of the 3019574 Captive Washer Cap Screw

The 3019574 Captive Washer Cap Screw is constructed with specific features that enhance its performance and durability. It is made from high-quality materials that provide strength and resistance to corrosion. The screw has a specific thread type that ensures a secure fit in the corresponding components. Additionally, the integrated washer is designed to provide an effective sealing surface, which contributes to the screw’s overall functionality.

Benefits of Using the 3019574 Captive Washer Cap Screw

The advantages of using the 3019574 Captive Washer Cap Screw include improved sealing capabilities, resistance to vibration, and ease of installation. These benefits contribute to the efficiency and reliability of truck operations by ensuring that components remain securely fastened under various conditions. The screw’s design also simplifies the installation process, reducing the time and effort required for maintenance tasks 3.

Installation and Usage Guidelines

To install the 3019574 Captive Washer Cap Screw, follow these steps: First, ensure that the mating surface is clean and free of debris. Next, align the screw with the designated hole and begin threading it in by hand to avoid cross-threading. Once the screw is started, use a torque wrench to tighten it to the manufacturer’s specified torque setting. This ensures that the screw is properly secured without over-tightening, which could damage the threads or the component being fastened.

Troubleshooting and Maintenance

Common issues with Captive Washer Cap Screws may include loosening over time or damage to the threads. To identify these issues, regularly inspect the screws during maintenance checks. If a screw appears loose or shows signs of wear, it should be tightened or replaced as necessary. To prolong the life of the screw, avoid over-tightening and ensure that the mating surfaces are kept clean and free of contaminants that could affect the screw’s performance.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins provides a wide range of components for the automotive industry, including heavy-duty trucks. The company’s products are known for their reliability and performance, making Cummins a trusted name in the industry for providing components that meet the rigorous demands of commercial applications.

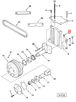

Captive Washer Cap Screw 3019574 in Cummins Engines

The Captive Washer Cap Screw part number 3019574 is a critical component in several Cummins engine models. This part is designed to secure various engine parts, ensuring stability and reliability during operation. Here is how it fits into different Cummins engines:

G855 and NH/NT 855 Engines

In the G855 and NH/NT 855 engines, the Captive Washer Cap Screw 3019574 is used to secure the engine’s internal components. Its design ensures that the washer remains captive, preventing it from being lost during assembly or maintenance. This is crucial for maintaining the integrity of the engine’s structure and ensuring that all parts remain properly aligned.

K50 Engine

The K50 engine also utilizes the Captive Washer Cap Screw 3019574 for securing various engine parts. Given the K50’s design, this screw is essential for maintaining the alignment and stability of components that are critical for the engine’s performance.

N14 CELECT and N14 CELECT PLUS Engines

In the N14 CELECT and N14 CELECT PLUS engines, the Captive Washer Cap Screw 3019574 plays a vital role in securing the engine’s internal components. The captive washer feature ensures that the screw does not come loose, which is crucial for the engine’s longevity and performance. This screw is used in areas where precise alignment and stability are necessary.

N14 MECHANICAL Engine

The N14 MECHANICAL engine also incorporates the Captive Washer Cap Screw 3019574. This screw is used to secure various parts within the engine, ensuring that they remain in place under the high stresses and vibrations typical of engine operation. The captive washer design is particularly beneficial in this engine model, as it helps maintain the structural integrity of the engine.

V903 Engine

In the V903 engine, the Captive Washer Cap Screw 3019574 is used to secure several critical components. Its design ensures that the washer remains in place, which is essential for maintaining the engine’s performance and reliability. This screw is used in areas where precise alignment and stability are necessary to prevent any potential failures.

Role of Part 3019574 Captive Washer Cap Screw in Engine Systems

The Part 3019574 Captive Washer Cap Screw is integral to the assembly and securement of various components within engine systems. Its application ensures that parts remain firmly in place, thereby contributing to the overall stability and efficiency of the engine.

In the Accessory Kit, this screw is used to attach additional components securely, ensuring they function as intended without the risk of detachment.

For the Adapter Front P.T.O. (Power Take-Off), the screw plays a role in maintaining the adapter’s alignment and connection to the engine, which is essential for the transfer of power to auxiliary equipment.

In the context of Brackets, such as the Fan & TCC Support and Fan & Supt TCC, the screw ensures that these brackets are tightly secured to the engine frame. This is vital for supporting the fan and torque converter cooling (TCC) systems, which are responsible for maintaining optimal engine temperatures.

The Damper Mounting relies on this screw to keep the vibration damper securely attached to the engine. This is important for reducing engine vibrations and ensuring smooth operation.

Within the Drive Arrangement and Fan Arrangements, the screw helps in securing the fan drive components, including the fan brace support and fan bracket. This ensures that the fan operates efficiently, contributing to effective engine cooling.

For the Fan Drive and its associated components like the fan drive arrangement and fan drive ratio (including the specific .75 to 1 ratio), the screw is used to maintain the precise alignment and secure attachment of these parts. This is essential for the fan to operate at the correct speed and efficiency.

The Fan Hub Bracket and Fan Mounting Brace also utilize this screw to ensure that the fan is firmly mounted and can withstand the operational stresses without shifting or becoming misaligned.

In the Fan Support Mounting Bracket, the screw ensures that the bracket is securely attached to the engine, providing a stable platform for the fan and other cooling components.

For the Heat Exchanger and Plumbing systems, particularly those involving Seawater and the Radiator Cooling System, the screw is used to secure various fittings and connections. This is important for maintaining the integrity of the cooling system and ensuring efficient heat exchange.

The Rod Support Mounting benefits from the use of this screw to keep the rods securely in place, which is essential for the structural integrity of the engine.

Lastly, in the Torque Converter Cooling and Torque Converter Cooling, the screw ensures that all components are tightly secured, allowing for efficient cooling of the torque converter and maintaining its performance.

Conclusion

The 3019574 Captive Washer Cap Screw by Cummins is a vital component in the maintenance and assembly of heavy-duty trucks and various Cummins engine models. Its design, featuring an integrated washer, ensures secure and vibration-resistant connections, contributing to the reliability and efficiency of truck and engine operations. Proper installation and maintenance of this screw are essential for the longevity and performance of the components it secures.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.